Method for preparing high-temperature compound bulk crystals

A compound, high-temperature technology, applied in the field of powder metallurgy, can solve the problems of high dislocation rate, low efficiency, and many micropores, and achieve the effects of low dislocation rate, high efficiency, and less parasitic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

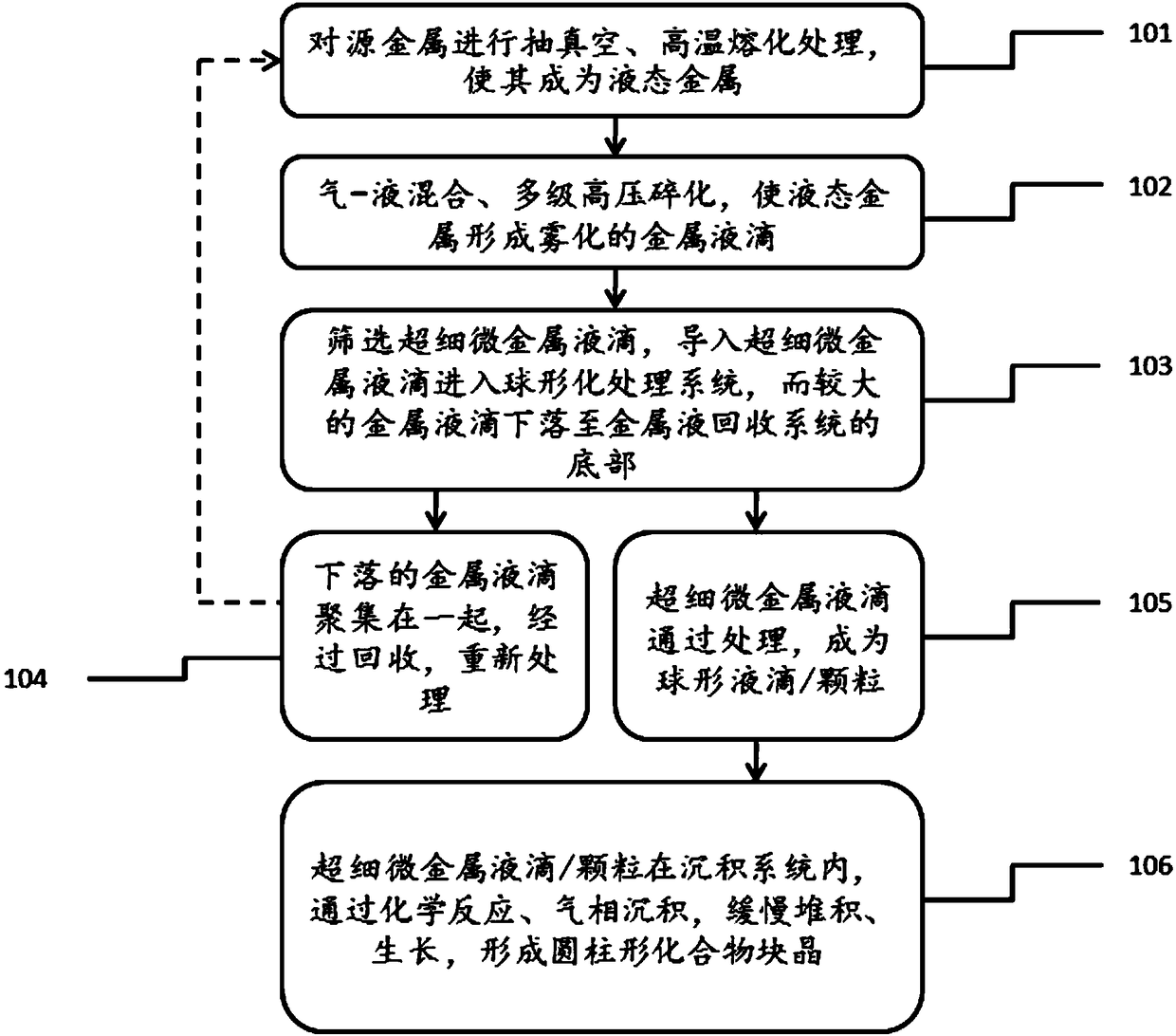

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

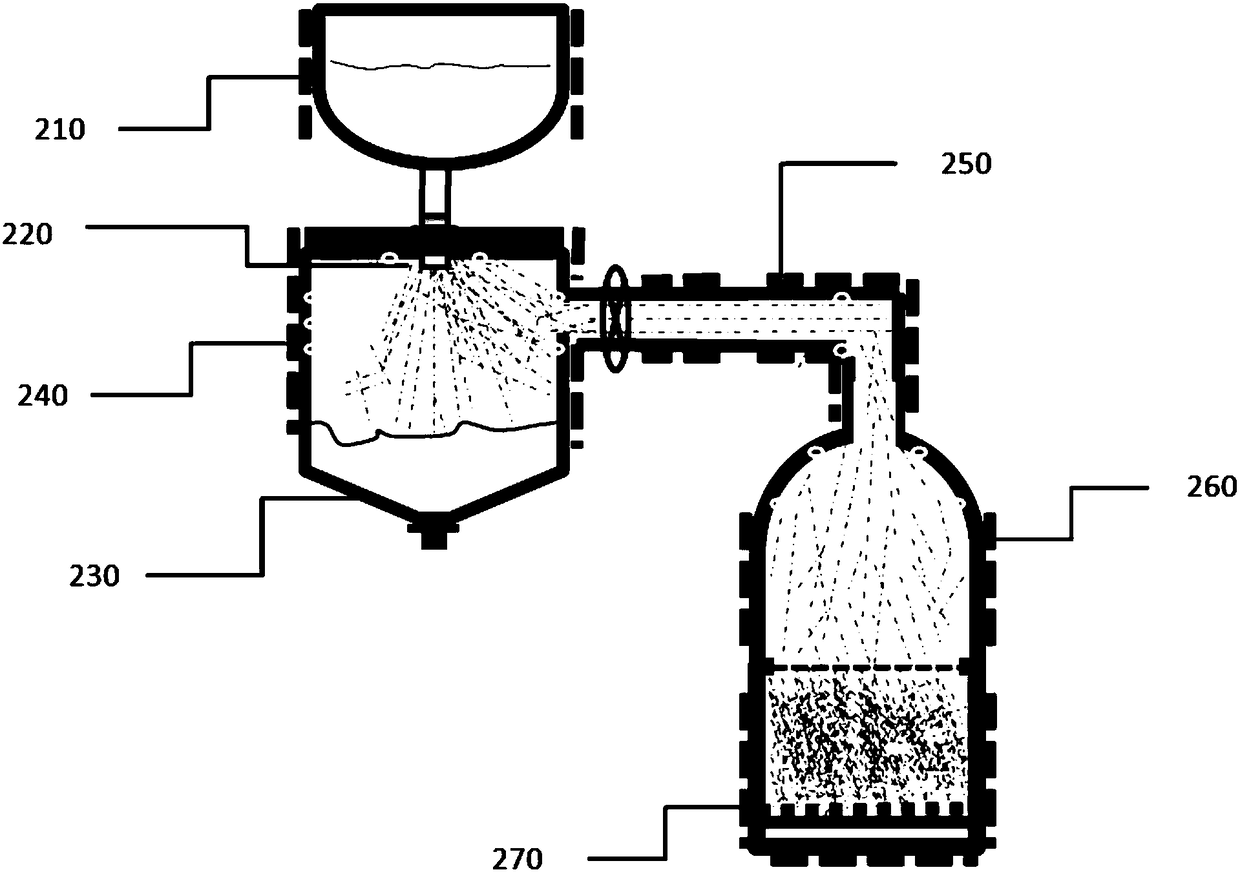

[0038] Such as figure 2 As shown, this embodiment includes a source metal liquefier 210, a high-pressure gas-liquid mixing atomizer 220, a filter 230, a molten metal recovery system 240, a particle preprocessor 250, a compound reactor 260 and a deposition grower 270; The source metal liquefier 210 is located above the high-pressure gas-liquid mixing atomizer 220, which heats and liquefies the source metal and transports it to the high-pressure gas-liquid mixing atomizer 220; the high-pressure gas-liquid mixing atomizer 220 is set in the metal liquid recovery system At the top of 240, the source metal liquid flow in the high-pressure gas-liquid mixing atomizer 220 forms fine or ultra-fine metal droplets through high-pressure stirring and mixing; On the processor 250, the ultra-fine metal droplets are introduced into the particle pre-processor 250 under the joint action of airflow drive and attraction; the metal liquid recovery system 240 is located below the source metal lique...

Embodiment 2

[0074] Such as Figure 10 As shown, this embodiment is used to prepare gallium nitride bulk material, and the specific process is as follows:

[0075] Step 201, vacuumize and heat pure gallium metal under vacuum conditions, and the heating temperature is higher than 29.78°C, so that gallium metal becomes liquid; inert gas nitrogen or argon participates in protection to prevent external impurity gas pollution;

[0076] Step 202, performing multi-stage high-pressure atomization on liquid gallium, performing gas-liquid mixing and multi-stage high-pressure crushing, so that it gradually becomes fine and ultrafine gallium metal droplets;

[0077] Step 203, use the gas and air flow screening system to screen the fine and ultrafine gallium metal droplets, and process them separately, so that the ultrafine gallium metal droplets / particles can smoothly enter the spheroidization processing system, while the larger and heavier The gallium metal droplets fall one after another and gather...

Embodiment 3

[0086] Such as Figure 11 As shown, this embodiment is used to prepare aluminum nitride bulk material, and the specific process is as follows:

[0087] Step 301, vacuumize and heat pure metal aluminum under vacuum conditions, and the heating temperature is higher than 660.4°C, so that the aluminum metal becomes liquid; inert gas nitrogen or argon participates in protection to prevent external impurity gas pollution;

[0088] Step 302, performing multi-stage high-pressure atomization on the liquid aluminum, performing gas-liquid mixing and multi-stage high-pressure crushing, so that it gradually becomes fine and ultra-fine aluminum metal droplets;

[0089] Step 203, use the gas and airflow screening system to screen the fine and ultra-fine aluminum metal droplets and process them separately, so that the ultrafine aluminum metal droplets / particles can smoothly enter the spheroidization processing system, while the larger and heavier The aluminum metal droplets fall one after an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com