A salt spray corrosion resistant electromagnetic shielding composite material and preparation method thereof

A composite material and electromagnetic shielding technology, applied in the field of composite materials, can solve the problems of high price, expensive rubber, cumbersome preparation methods, etc., and achieve the effects of excellent salt spray corrosion resistance, stable physical and mechanical properties, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

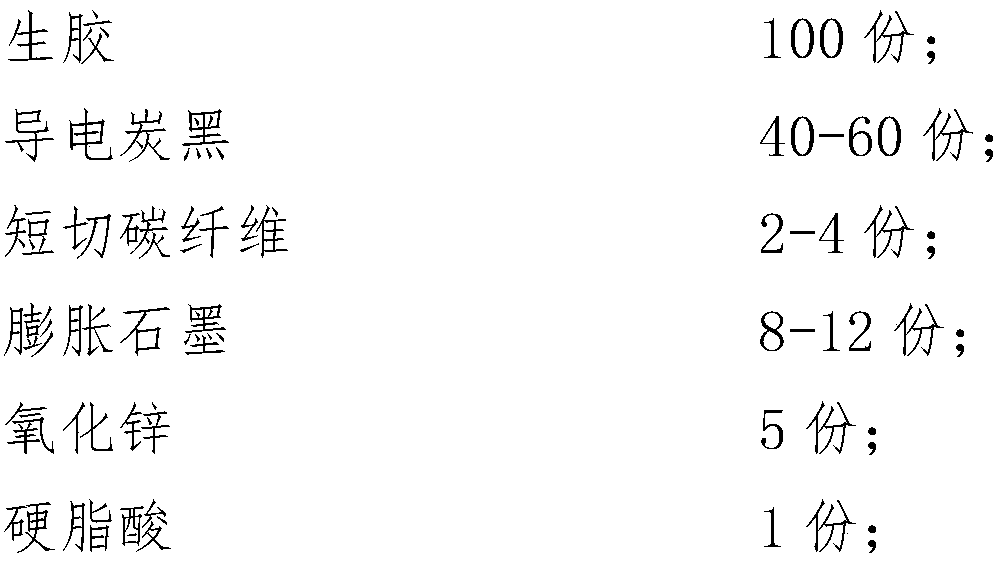

[0023] An electromagnetic shielding composite material resistant to salt spray corrosion, the main components of the composite material are by weight:

[0024]

[0025]

[0026] Concrete preparation steps are as follows:

[0027] 1) Pretreatment of expanded graphite: microwave the formulated amount of expandable graphite in a microwave oven for 15S to obtain expanded graphite, and then add the expanded graphite to the mixture of ethanol and distilled water, where the volume ratio of ethanol and distilled water is 1: 1. Ultrasonic treatment with 400W power for 6 hours, suction filtration of the mixed solution, vacuum drying of the resulting filter cake for 12 hours, and grinding the dried expanded graphite with a ball mill for 6 hours to obtain expanded graphite powder with a particle size of 100 mesh.

[0028] 2) Chopped carbon fiber treatment: prepare a hydroxypropyl methylcellulose dispersant with a mass fraction of 0.15% with water, and then add it to the beater accor...

Embodiment 2

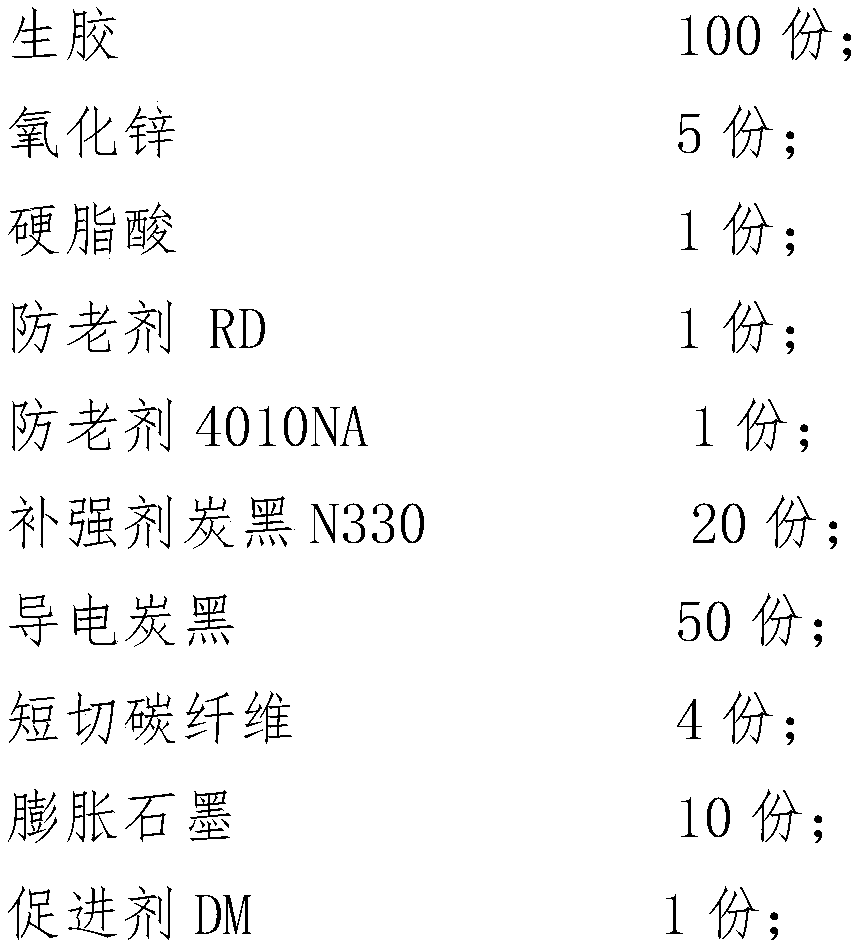

[0032] An electromagnetic shielding composite material resistant to salt spray corrosion, the composite material, in parts by weight, has the following main components:

[0033]

[0034]

[0035] Among them, chopped carbon fibers with a diameter of 3um and a length of 5mm were selected from Shanghai Lishuo Composite Material Technology Co., Ltd.

[0036] The processing method of embodiment 2 is the same as the processing method of embodiment 1.

Embodiment 3

[0038] An electromagnetic shielding composite material resistant to salt spray corrosion, the composite material, in parts by weight, has the following main components:

[0039]

[0040] Among them, chopped carbon fibers with a diameter of 4 um and a length of 6 mm were selected from Shanghai Lishuo Composite Material Technology Co., Ltd.

[0041] The processing method of embodiment 3 is the same as the processing method of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com