Rust-proof emulsion for spring and preparation method thereof

An anti-rust emulsion and pre-emulsion technology, which is applied in the field of springs, can solve the problems of flash corrosion, non-reusability, environmental pollution of waste liquid from phosphating treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

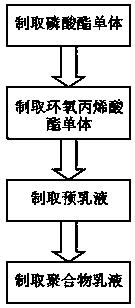

[0018] figure 1 It is the process step diagram of the antirust emulsion preparation method used for spring in the embodiment of the present invention; The preparation method comprises the following steps: a) preparing phosphate monomer, b) preparing epoxy acrylate monomer, c) preparing pre-emulsion, and d) preparing polymer emulsion.

[0019] The antirust emulsion used for springs mentioned in the present invention uses methyl methacrylate and butyl acrylate as comonomers, uses self-made epoxy acrylate monomers as functional monomers, and introduces self-made anti-flash corrosion Phosphate monomer, prepared by pre-emulsification process and semi-continuous seed polymerization method. Among them, the epoxy acrylate monomer can increase the crosslinking degree of the polymer emulsion, improve the compactness of the coating film formed by the antirust emulsion on the surface of the spring, and enhance the adhesion and salt water resistance of the coating film. Phosphate ester m...

Embodiment

[0021] The specific preparation method is as follows:

[0022] a) Preparation of phosphate monomer, the specific preparation process is as follows: firstly weigh 55% of hydroxyethyl acrylate, 12% of hydroquinone, and 33% of phosphorus pentoxide; Put the ester and hydroquinone in a stirring container, stir and mix in a water bath at 70°C, then slowly add phosphorus pentoxide, heat to 80°C after mixing, and perform esterification for 3 hours; then add a certain amount of deionized water to hydrolyze After 2h, the material is discharged, and the phosphoric ester monomer is obtained.

[0023] b) Preparation of epoxy acrylate monomer, the specific preparation process is: first weigh 44% of epoxy resin E-51, 52% of acrylic acid, and 4% of methyl methacrylate by weight percentage; Resin E-51 and acrylic acid were mixed in a stirring container, and added to react in a water bath at 98°C for 1.5 hours; then methyl methacrylate was added, mixed and reacted for 0.5 hours, and the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com