A kind of synthetic method and application of organosilicon modified polyurethane prepolymer

A technology of polyurethane prepolymer and synthesis method, which is applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problems of poor salt spray corrosion resistance and achieve good salt spray corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

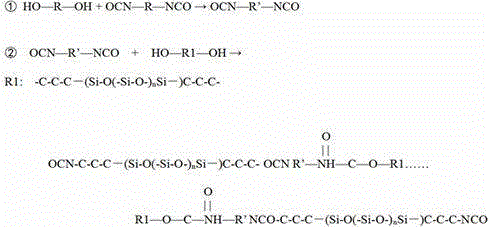

Method used

Image

Examples

Embodiment 1

[0014] Weigh 1800 grams of polyether diol D4000 into a three-necked flask, vacuum dehydrate at 120±5°C for 2~3 hours, then cool down to below 60°C, add 400 grams of diphenylmethane diisocyanate MDI100 in stages to control the reaction The temperature is 80±5°C, and the reaction is 2h. After the time is up, cool down to 50°C, and start to add 150 grams of alkoxysilicone oil BD-3253 prepared in advance dropwise, at a rate of 2 drops per second, and control the reaction temperature at 80±5°C until the addition is completed. The reaction was continued for 1 hour, and after the time was up, the temperature was lowered and the material was discharged to obtain a prepolymer for adhesive.

Embodiment 2

[0016] Weigh 1600 grams of polyether diol D4000 into a three-necked flask, vacuum dehydrate at 120±5°C for 2~3 hours, then cool down to below 60°C, add 360 grams of diphenylmethane diisocyanate MDI100 in stages to control the reaction The temperature is 80±5°C, and the reaction is 2h. After the time is up, cool down to 50°C, and start to add 150 grams of alkoxysilicone oil BD-3253 prepared in advance dropwise, at a rate of 2 drops per second, and control the reaction temperature at 80±5°C until the addition is completed. The reaction was continued for 1 hour, and after the time was up, the temperature was lowered and the material was discharged to obtain a prepolymer for adhesive.

Embodiment 3

[0018] Weigh 2000 grams of polyether diol D4000 into a three-necked flask, vacuum dehydrate at 120±5°C for 2~3 hours, then cool down to below 60°C, add 440 grams of diphenylmethane diisocyanate MDI100 in stages to control the reaction The temperature is 80±5°C, and the reaction is 2h. After the time is up, cool down to 50°C, and start to add 150 grams of alkoxysilicone oil BD-3253 prepared in advance dropwise, at a rate of 2 drops per second, and control the reaction temperature at 80±5°C until the addition is complete. The reaction was continued for 1 hour, and after the time was up, the temperature was lowered and the material was discharged to obtain a prepolymer for adhesive.

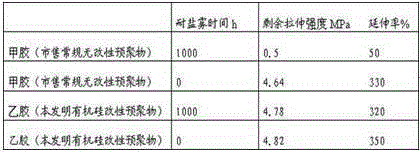

[0019] The comparative example of the application of the prepolymer of the present invention in the adhesive:

[0020] Take a commercially available conventional polyether-MDI (without any modification) prepolymer (commercially available brand is 6605E), and an appropriate amount of the silicone-mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com