Marine high-strength tear-resistant rubber material and preparation method thereof

A rubber material and high-strength technology, applied in the field of marine high-strength tear-resistant rubber materials and their preparation, to achieve the effects of good wear resistance, excellent solvent resistance, gas barrier properties, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

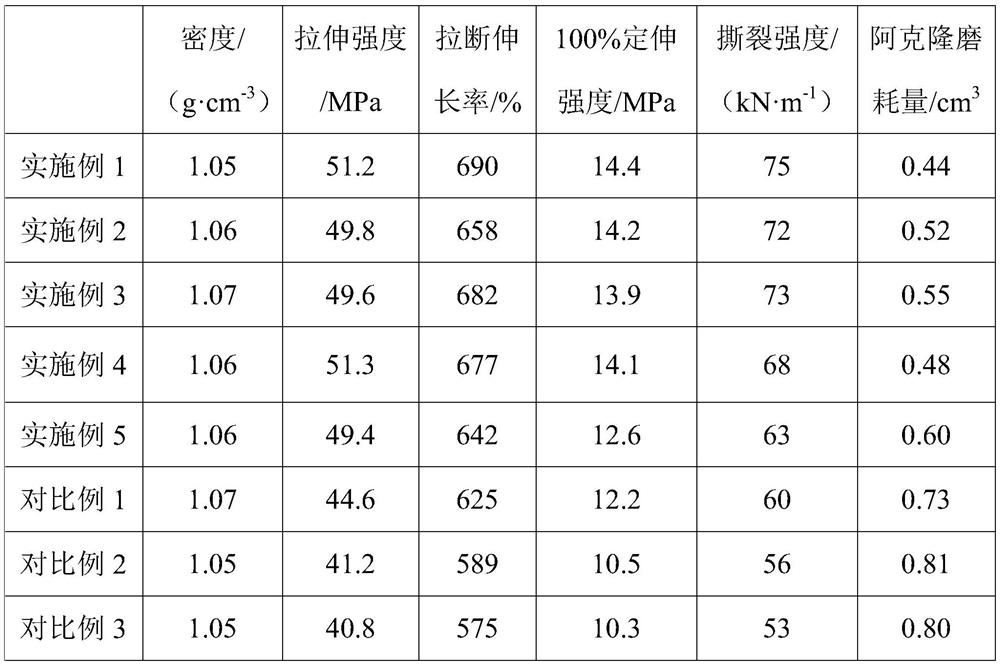

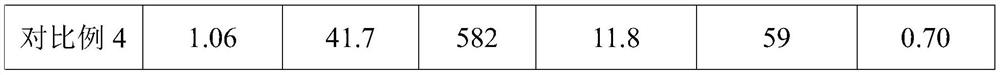

Examples

Embodiment 1

[0031] A high-strength tear-resistant rubber material for marine use, comprising the following components in parts by weight:

[0032] 50 parts of natural rubber, 10 parts of epoxidized natural rubber, 20 parts of aminated solution polystyrene-butadiene rubber, 25 parts of liquid polyisoprene rubber, 12 parts of epoxidized butadiene rubber, modified by coupling agent KH-550 20 parts of carbon nanotubes, 5 parts of white carbon black, 5 parts of carbon black, 10 parts of zinc oxide, 0.5 parts of sulfur, 0.1 parts of vulcanizing agent DCP, 0.1 parts of accelerator NS, 0.1 parts of accelerator DM, antioxidant KY-6160.1 parts, antioxidant 802 0.1 parts.

[0033] Wherein, the preparation method of aminated solution-polymerized styrene-butadiene rubber is as follows:

[0034] Under the protection of nitrogen, after mixing butadiene, styrene, 4-aminostyrene, and cyclohexane evenly, dilute butyllithium with tetrahydrofuran and add it. The ratio of butyllithium to tetrahydrofuran is 1...

Embodiment 2

[0042] A high-strength tear-resistant rubber material for marine use, comprising the following components in parts by weight:

[0043] 60 parts of natural rubber, 5 parts of epoxidized natural rubber, 20 parts of aminated solution-polymerized styrene-butadiene rubber, 25 parts of liquid polyisoprene rubber, 10 parts of epoxidized butadiene rubber, modified by coupling agent KH-550 15 parts of carbon nanotube, 6 parts of white carbon black, 6 parts of carbon black, 8 parts of zinc oxide, 0.5 part of sulfur, 0.1 part of vulcanizing agent DCP, 0.1 part of accelerator NS, 0.1 part of accelerator DM, antioxidant KY- 616 0.1 part, antioxidant 802 0.1 part.

[0044] Wherein, the preparation method of aminated solution-polymerized styrene-butadiene rubber is as follows:

[0045] Under the protection of nitrogen, after mixing butadiene, styrene, 4-aminostyrene, and cyclohexane evenly, dilute butyllithium with tetrahydrofuran and add it. The ratio of butyllithium to tetrahydrofuran is ...

Embodiment 3

[0053] A high-strength tear-resistant rubber material for marine use, comprising the following components in parts by weight:

[0054] 60 parts of natural rubber, 10 parts of epoxidized natural rubber, 30 parts of aminated solution polystyrene butadiene rubber, 30 parts of liquid polyisoprene rubber, 15 parts of epoxidized butadiene rubber, modified by coupling agent KH-550 20 parts of carbon nanotubes, 8 parts of white carbon black, 8 parts of carbon black, 0 parts of zinc oxide, 0.5 parts of sulfur, 0.1 parts of vulcanizing agent DCP, 0.1 parts of accelerator NS, 0.1 parts of accelerator DM, antioxidant KY- 616 0.1 part, antioxidant 802 0.1 part.

[0055] Wherein, the preparation method of aminated solution-polymerized styrene-butadiene rubber is as follows:

[0056] Under the protection of nitrogen, after mixing butadiene, styrene, 4-aminostyrene, and cyclohexane evenly, dilute butyllithium with tetrahydrofuran and add it. The ratio of butyllithium to tetrahydrofuran is 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com