A kind of high-strength wear-resistant modified natural rubber and its preparation method

A natural rubber, high-strength technology, applied in the field of high-strength wear-resistant modified natural rubber and its preparation, can solve the problems of low energy and simultaneously meet the mechanical strength of rubber, resistance to sunlight and ultraviolet aging, short service life, etc., and achieve good resistance. Sunlight and UV aging and weather resistance, good salt spray corrosion resistance, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

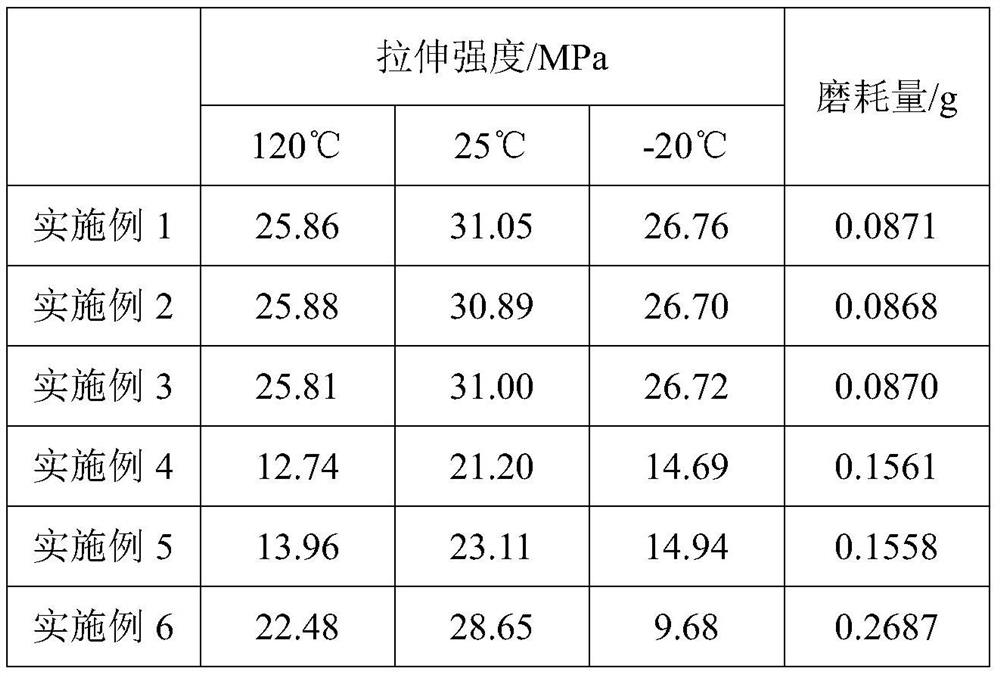

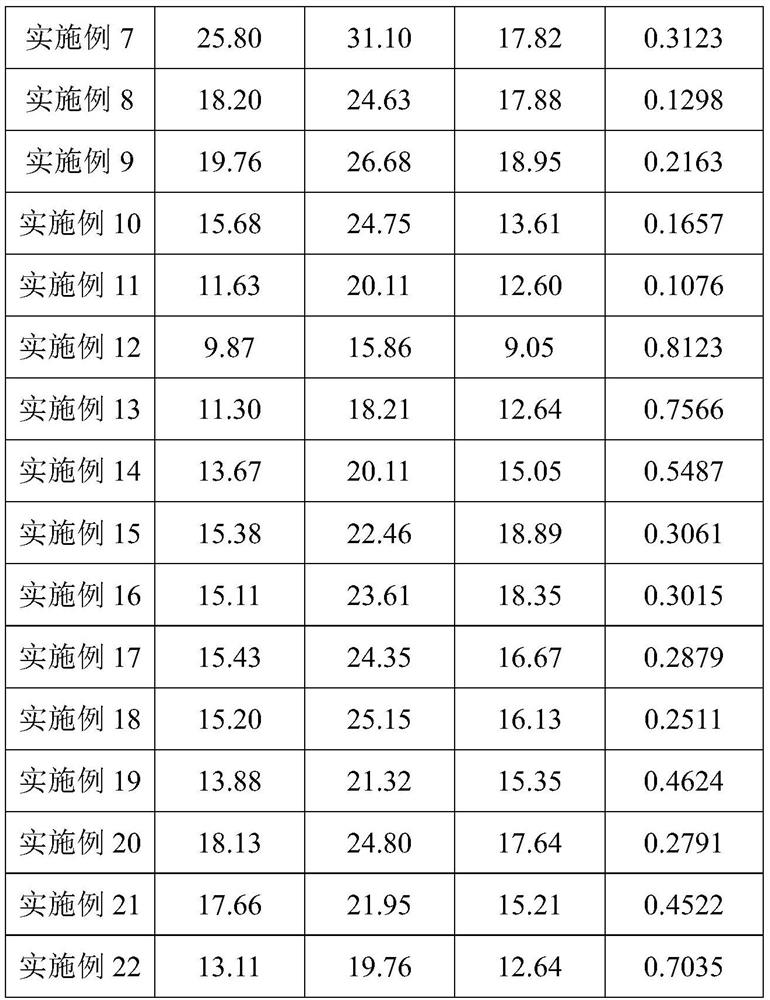

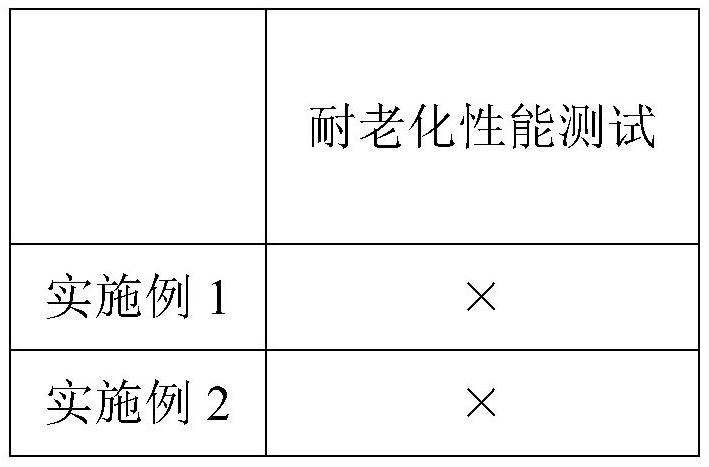

Examples

preparation example Construction

[0086] A second aspect of the present invention provides a method for preparing the high-strength wear-resistant modified natural rubber, comprising the following steps:

[0087] Step 1: Mix natural rubber, EPDM rubber, butadiene rubber, epoxy resin, and emulsifier in a mixer by parts by weight to obtain a rubber compound;

[0088] Step 2: Add reinforcing agent and silane coupling agent to the mixed rubber obtained in Step 1, after stirring, continue to add anti-aging agent, plasticizer and stir;

[0089] Step 3: continue to add the accelerator, and treat at 120°C-130°C and 165°C-175°C for 10-15 minutes, respectively, to obtain high-strength wear-resistant modified natural rubber.

[0090] In a preferred embodiment, the preparation method of the high-strength wear-resistant modified natural rubber comprises the following steps:

[0091] Step 1: In parts by weight, mix natural rubber, EPDM rubber, butadiene rubber, epoxy resin, and emulsifier in a mixer at 78-82°C at 235-245r / ...

Embodiment 1

[0102] Embodiment 1 of the present invention provides a high-strength wear-resistant modified natural rubber, comprising the following raw materials in parts by weight: 65 parts of natural rubber, 17.5 parts of EPDM rubber, 7.5 parts of butadiene rubber, 7.36 parts of carbon black, graphite 1.64 parts of alkene, 3 parts of epoxy resin, 2.5 parts of styrene ethyl trimethoxysilane, 1.5 parts of tetramethylthiuram disulfide, 1.5 parts of N-phenyl-N'-cyclohexyl-p-phenylenediamine, hard 0.22 parts of fatty acid, 0.18 parts of sodium octyl succinate sulfonate, and 4.8 parts of phenyl alkyl sulfonate.

[0103] The natural rubber is No. 1 standard rubber of Hainan Natural Rubber Industry Group Co., Ltd.; the Mooney viscosity (ML100°C 1+4) of the EPDM rubber is 55, purchased from Japan's Sumitomo Chemical ESPRENE series, and the model is 301; the butadiene rubber is Sinopec BR9000; the epoxy equivalent of the epoxy resin is 189g / eq, purchased from Nantong Xingchen Synthetic Materials C...

Embodiment 2

[0109] Embodiment 2 of the present invention provides a high-strength wear-resistant modified natural rubber, comprising the following raw materials in parts by weight: 60 parts of natural rubber, 15 parts of EPDM rubber, 6 parts of butadiene rubber, 6.4 parts of carbon black, graphite 1.6 parts of ene, 2.5 parts of epoxy resin, 2 parts of styrene ethyl trimethoxysilane, 1 part of tetramethylthiuram disulfide, 1 part of N-phenyl-N'-cyclohexyl-p-phenylenediamine, hard 0.17 parts of fatty acid, 0.13 parts of sodium octyl succinate sulfonate, and 4.5 parts of phenyl alkyl sulfonate.

[0110] The natural rubber is No. 1 standard rubber of Hainan Natural Rubber Industry Group Co., Ltd.; the Mooney viscosity (ML100°C 1+4) of the EPDM rubber is 55, purchased from Japan's Sumitomo Chemical ESPRENE series, and the model is 301; the butadiene rubber is Sinopec BR9000; the epoxy equivalent of the epoxy resin is 189g / eq, purchased from Nantong Xingchen Synthetic Materials Co., Ltd., the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com