Weather-resistant high-metal friction plate for military vehicle and preparation method thereof

A technology of high metal and friction linings, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of military vehicles such as weak action, excessive density, brake squealing, etc., and achieve excellent resistance to salt spray corrosion Performance, High and Stable Coefficient of Friction, Effect of Stable Coefficient of Friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

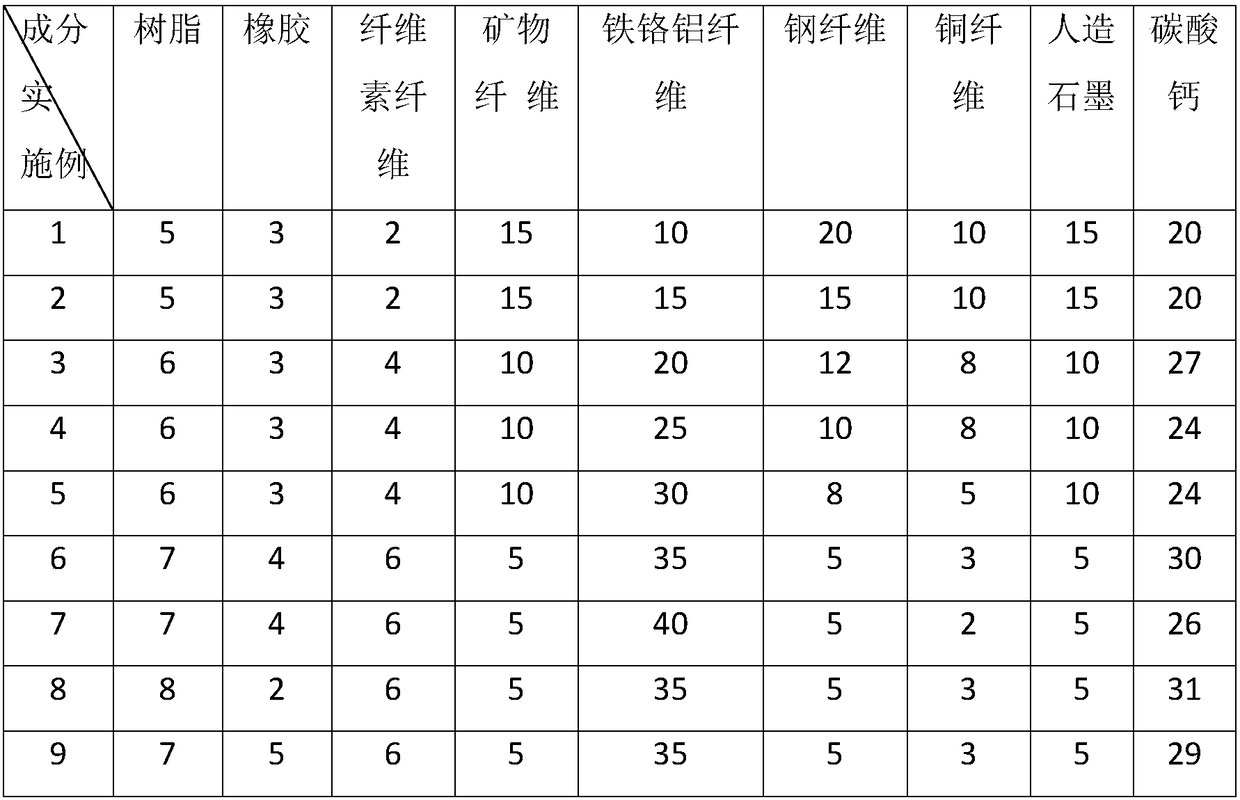

Examples

Embodiment 10

[0050] The raw material of the high-metal automobile friction sheet includes the following components calculated by weight percentage: 35% iron-chromium-aluminum fiber, containing carbon nanotube Ni 3 Al powder 5%, steel fiber 5%, copper fiber 3%, mineral fiber 5%, artificial graphite 5%, cellulose fiber 6%, resin 7%, rubber 4%, calcium carbonate 25%. After testing, the noise occurrence rate is 7.6%,

Embodiment 11

[0052] The raw material of the high-metal automobile friction sheet includes the following components calculated by weight percentage: 33% of iron-chromium-aluminum fiber, containing carbon nanotube Ni 3 Al powder 10%, steel fiber 5%, copper fiber 3%, mineral fiber 5%, artificial graphite 5%, cellulose fiber 6%, resin 7%, rubber 4%, calcium carbonate 22%. After testing, the noise occurrence rate is 5.4%.

Embodiment 12

[0054] The raw materials of the high-metal automobile friction sheet include the following components calculated by weight percentage: 30% of iron-chromium-aluminum fiber, containing carbon nanotube Ni 3 Al powder 15%, steel fiber 5%, copper fiber 3%, mineral fiber 5%, artificial graphite 5%, cellulose fiber 6%, resin 7%, rubber 4%, calcium carbonate 20%. After testing, the noise occurrence rate is 3.7%.

[0055] Ni containing carbon nanotubes 3 The preparation method of Al powder is as follows, in a tube furnace, at a catalytic temperature of 450°C-650°C, add methanol vapor at a rate of 1L / min to the carrier gas N at a rate of 2-8L / min. 2 In air, through porous Ni 3 In the pores of the Al alloy catalyst, methanol is catalyzed and decomposed in the pores and surfaces of the catalyst to obtain a mixture of black powder and catalyst powder. The catalytic time was adjusted, and in the mixtures prepared in Examples 10-12, the content of carbon nanotubes accounted for 4%, 5% and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com