Antibacterial blended textile and preparation technology thereof

A technology of blended fabric and preparation process, applied in the field of textile fabrics, can solve problems such as chemical pollution of chemical antibacterial agents, environmental damage, allergies, etc., and achieve the effects of being environmentally friendly, economical, and conducive to production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An antibacterial blended fabric consisting of the following raw materials by mass: 16 parts of short fiber silk, 2 parts of nano-bamboo charcoal fiber, 1 part of silver ion fiber, 4 parts of aloe fiber, 40 parts of cotton fiber, 22 parts of polyester fiber, 10 parts of cupronickel fiber and 20 parts ronsale fiber.

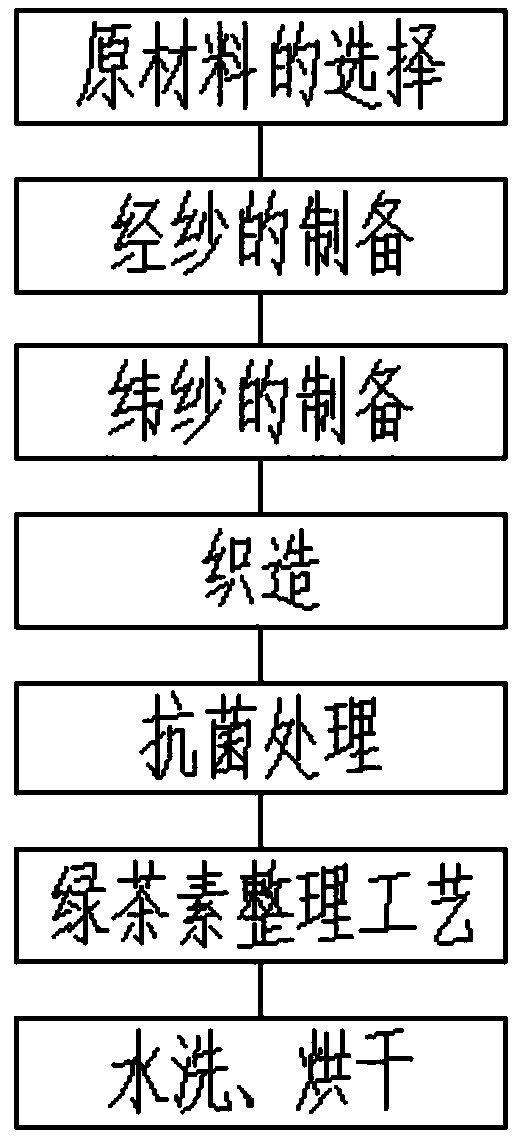

[0023] A preparation process of antibacterial blended fabrics. After the selection of raw materials, preparation of warp yarns, preparation of weft yarns, weaving, antibacterial treatment, green tea finishing process, washing and drying steps, the preparation process of antibacterial blended fabrics is completed; specific steps as follows:

[0024] (1) Selection of raw materials: select the following fibers by mass as raw materials: 16 parts of short fiber silk, 2 parts of nano-bamboo charcoal fiber, 1 part of silver ion fiber, 4 parts of aloe fiber, 40 parts of cotton fiber, 22 parts of polyester fiber, 10 parts of Part cupronickel fiber and 20 parts Ronsa...

Embodiment 2

[0033] An antibacterial blended fabric is composed of the following raw materials by mass: 22 parts of short fiber silk, 8 parts of nano-bamboo charcoal fiber, 5 parts of silver ion fiber, 8 parts of aloe fiber, 60 parts of cotton fiber, 32 parts of polyester fiber, 16 parts of Cupronickel fiber and 40 parts of Ronsale fiber.

[0034] A preparation process of antibacterial blended fabrics. After the selection of raw materials, preparation of warp yarns, preparation of weft yarns, weaving, antibacterial treatment, green tea finishing process, washing and drying steps, the preparation process of antibacterial blended fabrics is completed; specific steps as follows:

[0035] (1) Selection of raw materials: select the following fibers by mass as raw materials: 22 parts of short fiber silk, 8 parts of nano-bamboo charcoal fiber, 5 parts of silver ion fiber, 8 parts of aloe fiber, 60 parts of cotton fiber, 22-32 parts of polyester fiber , 16 parts of cupronickel fiber and 40 parts ...

Embodiment 3

[0044] An antibacterial blended fabric is composed of the following raw materials by mass: 19 parts of short fiber silk, 5 parts of nano-bamboo charcoal fiber, 3 parts of silver ion fiber, 6 parts of aloe fiber, 50 parts of cotton fiber, 27 parts of polyester fiber, 13 parts of cupronickel fiber and 30 parts ronsale fiber.

[0045] A preparation process of antibacterial blended fabrics. After the selection of raw materials, preparation of warp yarns, preparation of weft yarns, weaving, antibacterial treatment, green tea finishing process, washing and drying steps, the preparation process of antibacterial blended fabrics is completed; specific steps as follows:

[0046] (1) Selection of raw materials: select the following fibers by mass as raw materials: 19 parts of short fiber silk, 5 parts of nano-bamboo charcoal fiber, 3 parts of silver ion fiber, 6 parts of aloe fiber, 50 parts of cotton fiber, 27 parts of polyester fiber, 13 parts of Part cupronickel fiber and 30 parts Ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com