Electroplating method

A technology of copper plating and plating solution, applied in the field of surface treatment, which can solve problems such as dynamic embrittlement and thermal cracking of the coating surface, and achieve the effect of improving wear resistance and salt spray corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

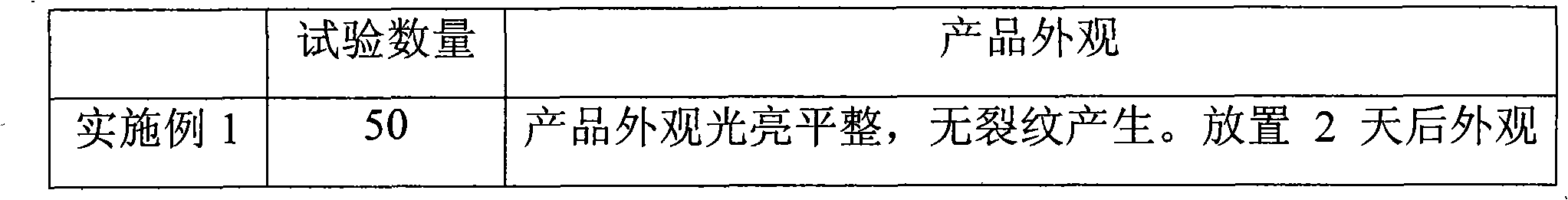

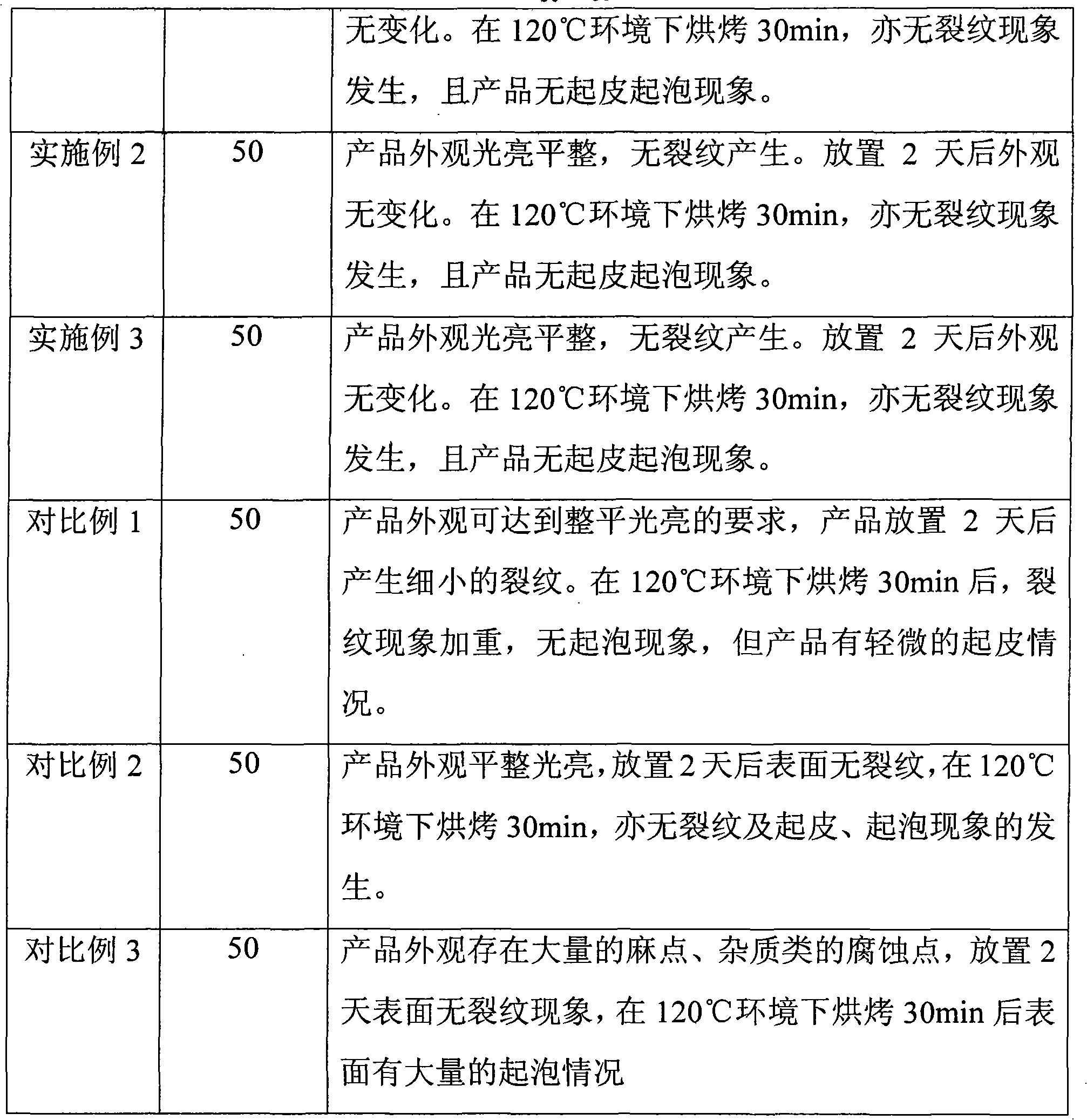

Examples

Embodiment 1

[0038] (1) polishing

[0039] The AZ91D magnesium alloy die-casting is mechanically polished with a 1*10-inch buckle cloth wheel combined with a 1*10-inch small wool wheel polishing method to remove burrs, scale, etc. produced by the raw material itself during the die-casting process and reduce surface roughness High degree, improve the mirror bright effect and enhance the binding force of subsequent electroplating.

[0040] (2) wax removal

[0041] The above-mentioned polished magnesium alloy die castings were dewaxed with Procleaner BR#1 universal dewaxing water from Yongxing Chemical Co., Ltd., the volume of the cylinder was 30ml / L, the working temperature was 80°C, and the wax was removed in an ultrasonic environment for 5min.

[0042] (3) Degreasing:

[0043] The above-mentioned magnesium alloy die casting after dewaxing is degreased by cathodic electrolysis, the electrolyte is: sodium phosphate 30g / L, sodium carbonate 30g / L; the degreasing temperature is 60°C, the degr...

Embodiment 2

[0061] Steps (1)-(6) are the same as in Example 1.

[0062] (7) Pre-plating copper:

[0063] The magnesium alloy die-casting after above-mentioned galvanizing is carried out pre-plating copper, and the plating solution of pre-plating copper is: copper pyrophosphate 15 grams / liter, potassium pyrophosphate 380 grams / liter, ethylenediaminetetraacetic acid 3 grams / liter, lemon Potassium sulfamate 7 g / L, potassium sulfamate 0.6 g / L and potassium dithiocarbonate 0.15 g / L. Adjust the pH value of the plating solution with phosphoric acid to make the pH 7.5, the plating time is 5min, and the current density is 1A / dm 2 .

[0064] (8) Acid bright copper:

[0065] Bright copper plating is carried out on the magnesium alloy die-casting parts after the above pre-copper plating. This process adopts the UB-X series acid bright copper plating electroplating process produced by Yongxing Chemical. The working temperature of acid bright copper plating is 30℃, the working time is 30min, and th...

Embodiment 3

[0073] Steps (1)-(6) are the same as in Example 1.

[0074] (7) Pre-plating copper:

[0075] Pre-plate copper on the magnesium alloy die-casting after the above-mentioned zinc dipping, and the plating solution for pre-plating copper is: copper pyrophosphate 20 grams / liter, potassium pyrophosphate 300 grams / liter, ethylenediaminetetraacetic acid 2 grams / liter, lemon potassium sulfamate 5 g / L, potassium sulfamate 0.3 g / L and potassium dithiocarbonate 0.1 g / L. Adjust the pH value of the plating solution with phosphoric acid to make the pH 7.0, the plating time is 5min, and the current density is 1A / dm 2 .

[0076] (8) Acid bright copper:

[0077] Bright copper plating is carried out on the magnesium alloy die-casting parts after the above-mentioned pre-copper plating. This process adopts the UB-X series acidic bright copper plating electroplating process produced by Yongxing Chemical. The working temperature of acid bright copper plating is 30℃, the working time is 30min, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com