Welding method of cupronickel weldment

A welding method and technology for welding parts, which are applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of plasticity and toughness of welded joints, and coarse grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0080] Example 1, for a cupronickel pipe with a specification of φ73×7.01mm,

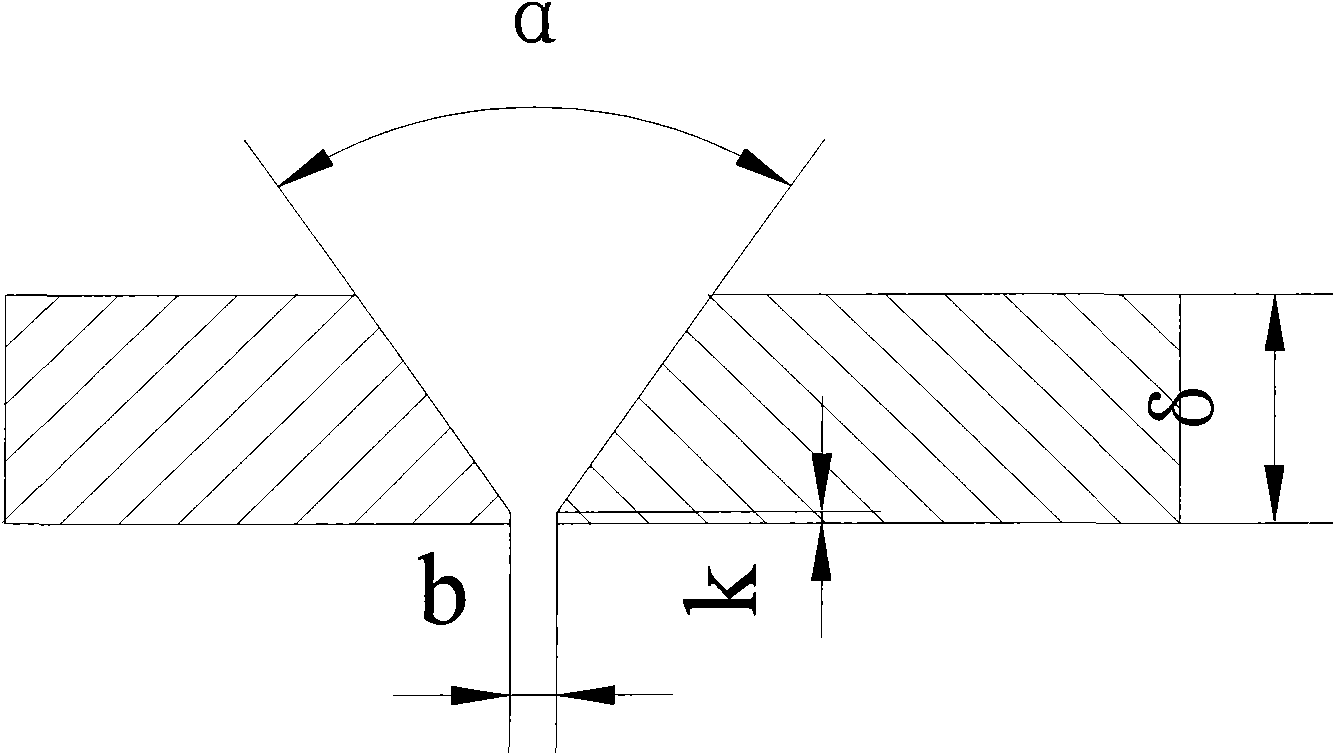

[0081] 1) Process the groove of the welded joint of the weldment: the thickness of the weldment δ=7.01mm, the gap of the groove b=2.0mm, the blunt edge k=0.8mm, the angle of the groove α=75°;

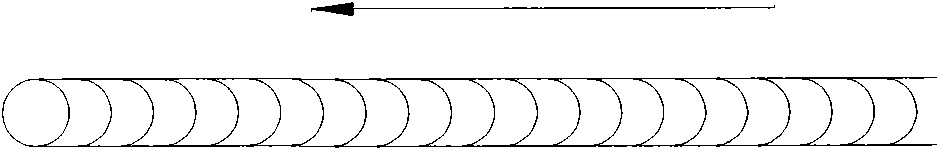

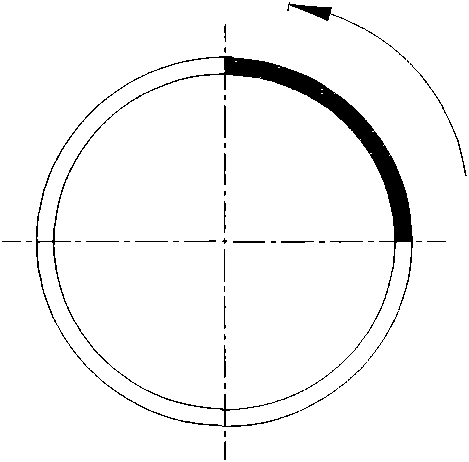

[0082] 2) The form of the fixed welding seam during assembly; the fixed welding seam adopts the "bow bridge method";

[0083] 3) Select the welding wire, clean the welding wire and the surface of the weldment, and weld according to the welding process and operation requirements:

[0084] Welding processes include:

[0085] 1) Power polarity: DC positive.

[0086] 2) Preheating temperature and interlayer temperature: without preheating, the interlayer temperature is 120°C.

[0087] 3) The number of welding layers and the height of the welding seam: 3 layers of welding are used, and the height of each welding seam is controlled at about 3.5mm.

[0088] 4) Protective gas: Inflatable protection must be carrie...

example 2

[0098] Example 2, for a cupronickel pipe with a specification of φ60×3.8mm,

[0099] 1) Process the groove of the welded joint of the weldment: the thickness of the weldment δ=3.8mm, the gap of the groove b=1.5mm, the blunt edge k=0.3mm, the angle of the groove α=70°;

[0100] 2) The form of the fixed welding seam during assembly; the fixed welding seam adopts the "bow bridge method";

[0101] 3) Select the welding wire, clean the welding wire and the surface of the weldment, and weld according to the welding process and operation requirements:

[0102] Welding processes include:

[0103] 1) Power polarity: DC positive.

[0104] 2) Preheating temperature and interlayer temperature: no preheating.

[0105] 3) The number of welding layers and the height of welding seam: single-layer welding is adopted.

[0106] 4) Protective gas: Inflatable protection must be carried out inside the tube, and a gas protective cover is not required outside the tube. Argon is used as the prote...

example 3

[0117] Example 3, for a cupronickel pipe with a specification of φ100×15mm,

[0118] 1) Process the groove of the welded joint of the weldment: the thickness of the weldment δ = 15mm, the gap of the groove b = 3mm, the blunt edge k = 1mm, and the angle of the groove α = 65°;

[0119] 2) The form of the fixed welding seam during assembly; the fixed welding seam adopts the "bow bridge method";

[0120] 3) Select the welding wire, clean the welding wire and the surface of the weldment, and weld according to the welding process and operation requirements:

[0121] Welding processes include:

[0122] 1) Power polarity: DC positive.

[0123] 2) Preheating temperature and interlayer temperature: preheat 130°C before welding; during multilayer welding, the interlayer temperature should not be lower than 140°C.

[0124] 3) The number of welding layers and the height of the welding seam: 5 layers of welding are used, and the height of the welding seam of each layer is controlled at abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com