Iron alloy additive containing low titanium and phosphorus and use method of iron alloy additive

A low-titanium ferrophosphorus and additive technology, applied in the field of ferroalloy production, can solve the problems of high cost, large fluctuations in phosphorus content, high impurity content, etc., and achieve the effect of moderate particle size and rich element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

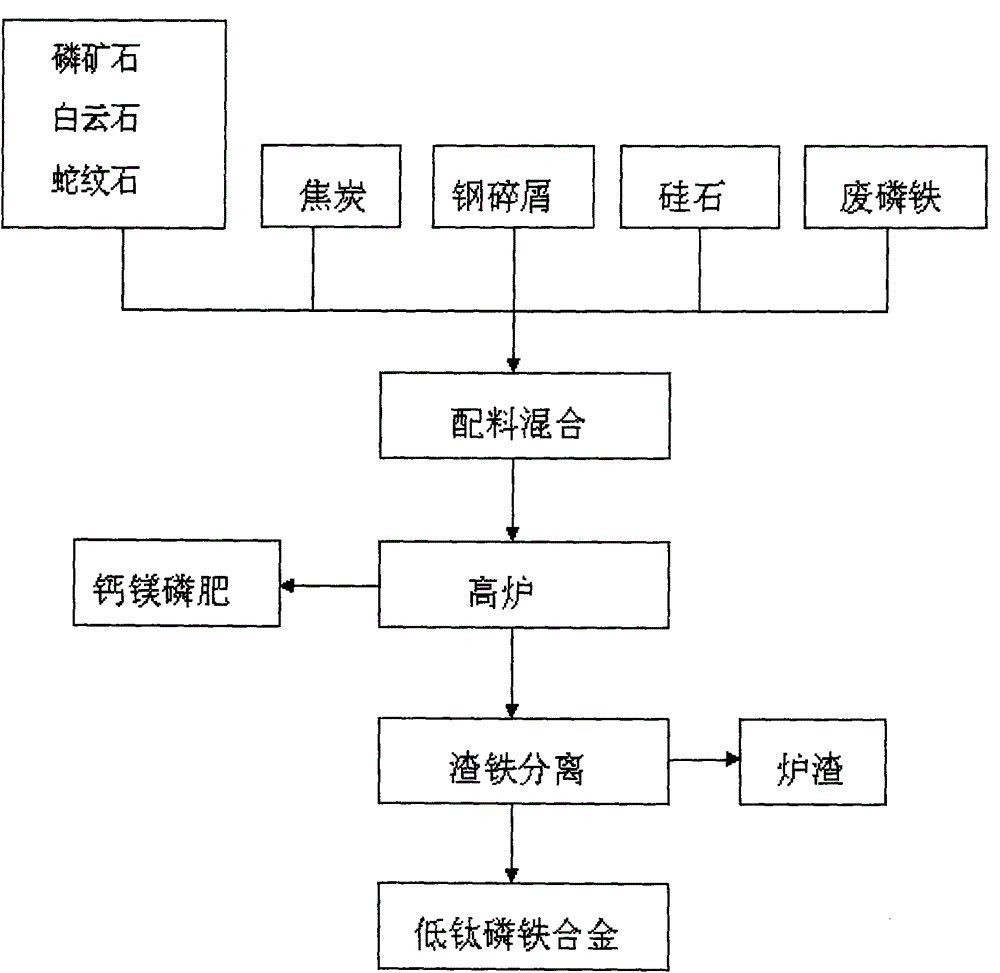

[0035] The preparation method of low-titanium phosphorus ferroalloy additive of the present invention:

[0036] (1) Selection of raw materials:

[0037] Phosphate rock: phosphorus pentoxide ≥ 22%

[0038] Coke: carbon ≥ 70%

[0039] Dolomite: calcium oxide ≥ 20%

[0040] Silica: silicon dioxide ≥ 90%

[0041] Serpentine: Magnesium oxide ≥ 31%

[0042] (2) The above-mentioned raw materials are put into a blast furnace of 50 cubic meters or 100 cubic meters in proportion, melted at a high temperature of 1550°C and undergo a chemical reduction reaction, and the molten material of the reaction product is discharged from the slag port of the blast furnace;

[0043] (3) Spray the melt flow with a water flow of 0.5MPa to break it into fine particles, and the product phosphorus

[0044] Due to its high specific gravity, ferroalloys are precipitated at the bottom of the blast furnace.

Embodiment 2

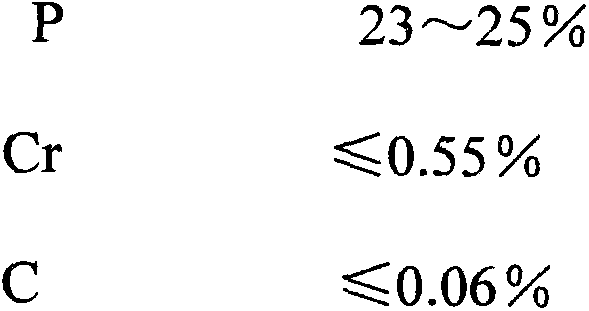

[0046] A kind of low-titanium phosphorus iron alloy additive, its component content is as follows:

[0047]

Embodiment 3

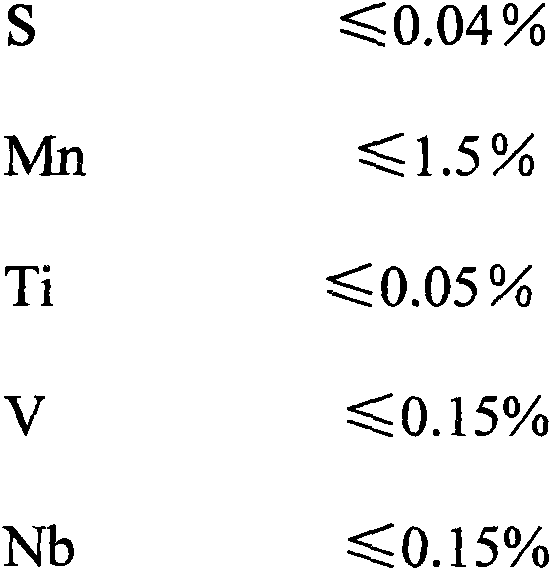

[0049] A kind of low-titanium phosphorus iron alloy additive, its component content is as follows:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com