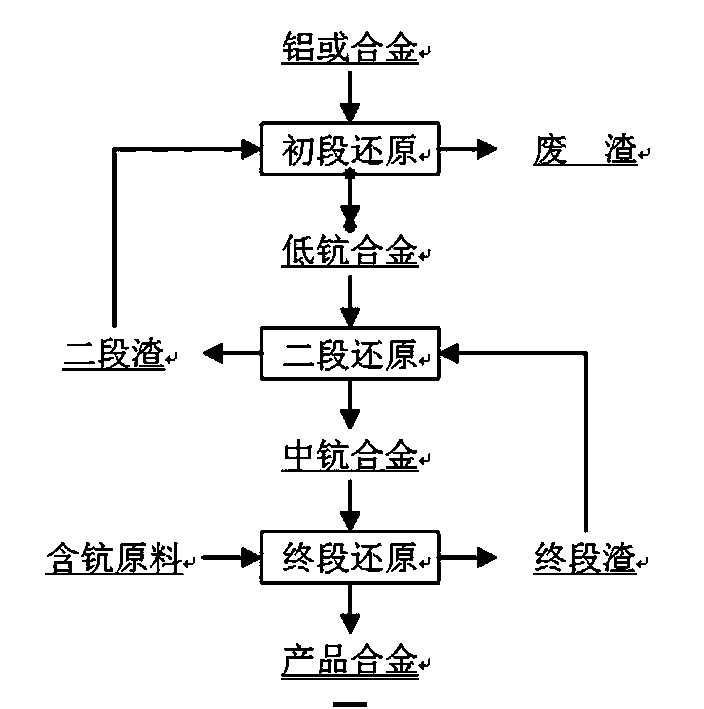

Method for preparing aluminum-scandium alloy by segmental countercurrent reduction method

A reduction method and aluminum alloy technology, applied in the field of preparation of aluminum-scandium alloy, can solve the problems of expensive raw materials, limited application range, low recovery rate, etc., and achieve the effect of increasing the actual yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Using the traditional non-vacuum aluminothermic reduction method, with Sc 2 o 3 As a raw material, molten Al liquid is used as a reducing agent, and a smelting aid is added to reduce it to an Al-Sc alloy containing 2% scandium at high temperature. Adopt this method yield to be no more than 80%, according to existing Sc 2 o 3 Calculated at a price of 6,000 yuan / kg, the raw material cost per ton of alloy is about 247,000 yuan (about 38.33 kilograms of scandium oxide and 1,000 kilograms of aluminum), and the cost of reduction smelting process (auxiliaries, energy, labor and equipment depreciation, etc.) is about 1,000 yuan / t , the total production cost of the alloy is about 248,000 yuan / t.

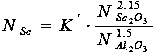

[0050] 2. The non-vacuum aluminothermic reduction method is also adopted, and the reduction process is carried out using the three-stage method described in the present invention: the initial metal is pure aluminum, and the initial scandium source is Sc 2 o 3 . The reaction pr...

Embodiment 2

[0053] 1. Using the traditional non-vacuum aluminum-magnesium thermal reduction method, using ScCl 3 As the raw material, the molten Al-5%Mg alloy solution is used as the reducing agent, and a smelting aid is added to reduce it to an Al-Sc alloy containing 2% scandium at high temperature. Adopt this method yield to calculate by 90%. Because of ScCl 3 Usually by Sc 2 o 3 Chlorination is obtained, theoretically per kg Sc 2 o 3 2.2 kg of ScCl can be obtained 3 , considering the yield and preparation cost, according to the existing Sc 2 o 3 The price is 6000 yuan / kg converted to ScCl 3 The price is calculated at 3,000 yuan / kg, and the raw material cost per ton of alloy is about 242,000 yuan (about 74.95 kilograms of ScCl 3 and 1,000 kg of aluminum-magnesium alloy), the reduction smelting process cost (auxiliaries, energy, labor and equipment depreciation, etc.) is about 1,000 yuan / t, and the total production cost of the alloy is about 243,000 yuan / t. This product contain...

Embodiment 3

[0057] 1. Using the traditional non-vacuum alumino-calcium thermal reduction method, with Na 3 AlF 6 -Sc 2 o 3 The molten salt is used as the raw material, and the molten Al-0.5% Ca alloy solution is used as the reducing agent, which is reduced to Al-Sc alloy containing 2% scandium at high temperature. Although Ca is more reducible than Mg, it cannot remain as an impurity in the aluminum alloy, so the amount of Ca added is limited, and the yield of Sc is lower than that of the aluminum-magnesium alloy thermal reduction method. Referring to the Sc yield of the non-vacuum aluminothermic reduction method and the aluminum-magnesium alloy thermal reduction method, the Sc yield is calculated at 85%, and the existing Sc 2 o 3 Calculated at a price of 6,000 yuan / kg, the raw material cost per ton of alloy is about 234,000 yuan (about 36.08 kilograms of scandium oxide and 1,000 kilograms of aluminum-calcium alloy), and the cost of reduction smelting process (auxiliaries, energy, lab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com