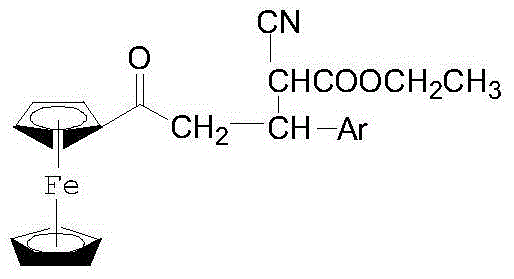

1-Ferrocenyl-3-aryl-3-diacetylmethylene-acetone and preparation method thereof

A technology of diacetylmethine and ferrocenyl, which is applied in the field of chemical synthesis, can solve the problems of low yield, long reaction time, and large amount of solvent used, and achieve simple reaction process, short reaction time, and equipment less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

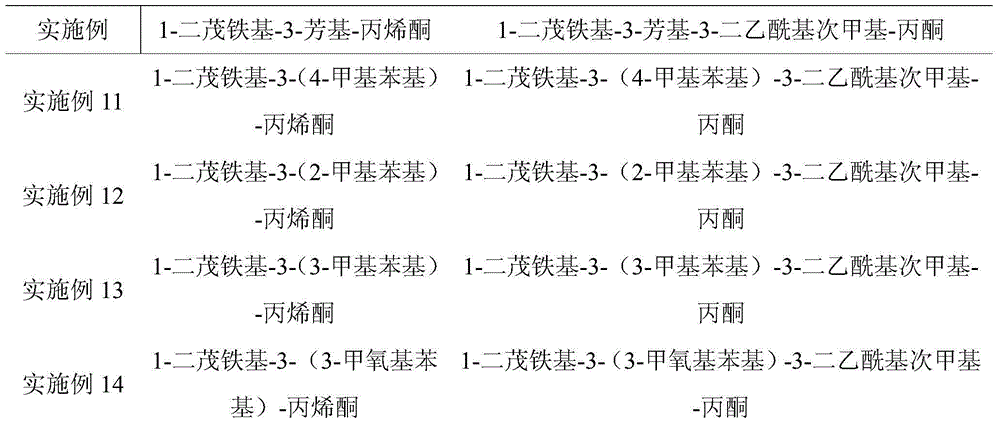

Examples

preparation example Construction

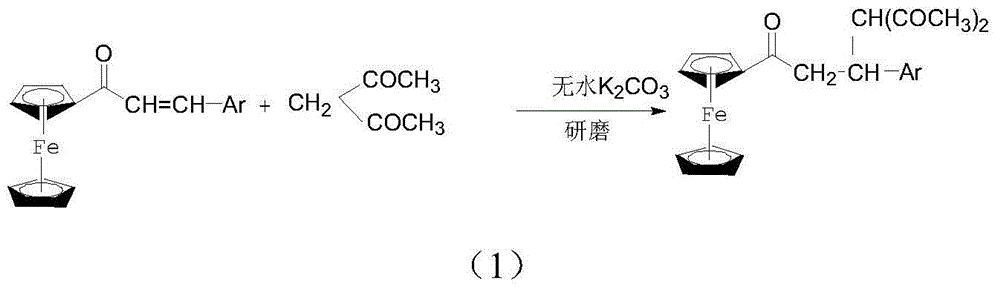

[0043] A preparation method of 1-ferrocenyl-3-aryl-3-diacetylmethine-acetone, comprising the following steps:

[0044] Step 1) A mol1-ferrocenyl-3-aryl-propenone, B mol anhydrous K 2 CO 3 (or NaOH), C mol acetylacetone was added into a dry mortar and ground rapidly at room temperature until the reaction was completed, the grinding time was 5-10min, and TLC was used to detect the reaction process during the reaction. When 1-ferrocenyl-3-aryl- When the raw material point of acryl ketone disappears, it means that the raw material has completely reacted; the developer of TLC is a mixed solvent of ethyl acetate and petroleum ether with a volume ratio of 1:3. After the reaction is complete, the crude product is obtained.

[0045] Step 2) The crude product was washed with water and suction filtered several times, and was washed with water until the pH value of the filtrate was neutral, and the filter cake was vacuum-dried at a temperature of 20-30° C. for 20-30 hours to obtain 1-dim...

Embodiment 1

[0049] Weigh 0.0012mol acetylacetone, 0.0012mol anhydrous K 2 CO 3Put it in a mortar and mix quickly and evenly, then add 0.001mol 1-ferrocenyl-3-phenyl-propenone, mix and grind at room temperature for 9 minutes. The mixture will start to become viscous as the reaction proceeds, continue to grind until the substance no longer changes, use thin layer chromatography to monitor the reaction progress, when the raw material point of 1-ferrocenyl-3-phenyl-propenone disappears, it indicates that the raw material Complete reaction, after the reaction is completed, wash and filter with pure water several times, wash with water until the pH value of the filtrate is neutral, vacuum dry, vacuum dry, vacuum drying temperature is 25 ° C, time 24h, to obtain a reddish-brown solid, namely 1-Ferrocenyl-3-phenyl-3-diacetylmethine-acetone was obtained. The m.p. is 106°C-108°C.

[0050] IR (KBr tablet) ν (cm -1 ): 3100, 2937, 2869, 1712, 1391; 1 H NMR: 7.09-8.01 (m, 5H, Ar-H), 4.45-4.93 (m, ...

Embodiment 2

[0052] Weigh 0.0012mol acetylacetone, 0.0012mol anhydrous K 2 CO 3 Place in a mortar and mix quickly and evenly, then add 0.001mol 1-ferrocenyl-3-(p-chlorophenyl)-propenone, mix and grind at room temperature for 8 minutes. The mixture will start to become viscous as the reaction progresses, continue to grind until the substance no longer changes, use thin layer chromatography to monitor the reaction progress, when the raw material point of 1-ferrocenyl-3-(p-chlorophenyl)-propenone When it disappears, it means that the raw materials are completely reacted. After the reaction is completed, wash and filter with pure water for many times. When filtering, wash with water until the pH value of the filtrate is neutral. Then vacuum dry. The vacuum drying temperature is 25 ° C and the time is 24 hours. Red solid, that is, 1-ferrocenyl-3-(p-chlorophenyl)-3-diacetylmethine-acetone. The m.p. is 147°C-150°C.

[0053] IR (KBr tablet) ν (cm -1 ): 3150, 2971, 2839, 1647, 1374, 825; 1 H N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com