Welding protection method for improving welding quality

A welding quality and post-welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of costing hundreds of yuan, the protection device is not versatile and low, and each set costs thousands to tens of thousands of yuan, etc. problem, to achieve the effect of suppressing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

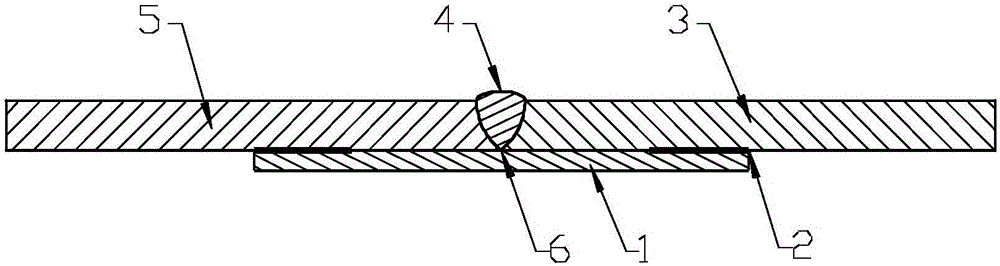

[0009] Such as figure 1 As shown, the welding protection method of the present invention to improve welding quality, before welding, on the back side 6 of the welding seam of the base metal 3 and the base metal 5 to be welded, the metal foil strip 1 is pasted along the welding seam by an adhesive 2 On the surface of the welding seam, welding is then performed, and after welding, the metal foil strip 1 and the adhesive 2 are removed.

[0010] The material of the metal foil strip 1 is copper.

[0011] The back protection welding of the exhaust nozzle of a certain type of engine is an example: the exhaust nozzle is a high-temperature alloy sheet metal part, the total length of the welded assembly exceeds 1.6 meters, and the diameter exceeds 0.5 meters. The method of protecting the welding with a vacuum argon box only costs millions of yuan for the vacuum argon box, and tens of thousands of yuan for protection with special tooling. The method of applying the metal foil tape on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com