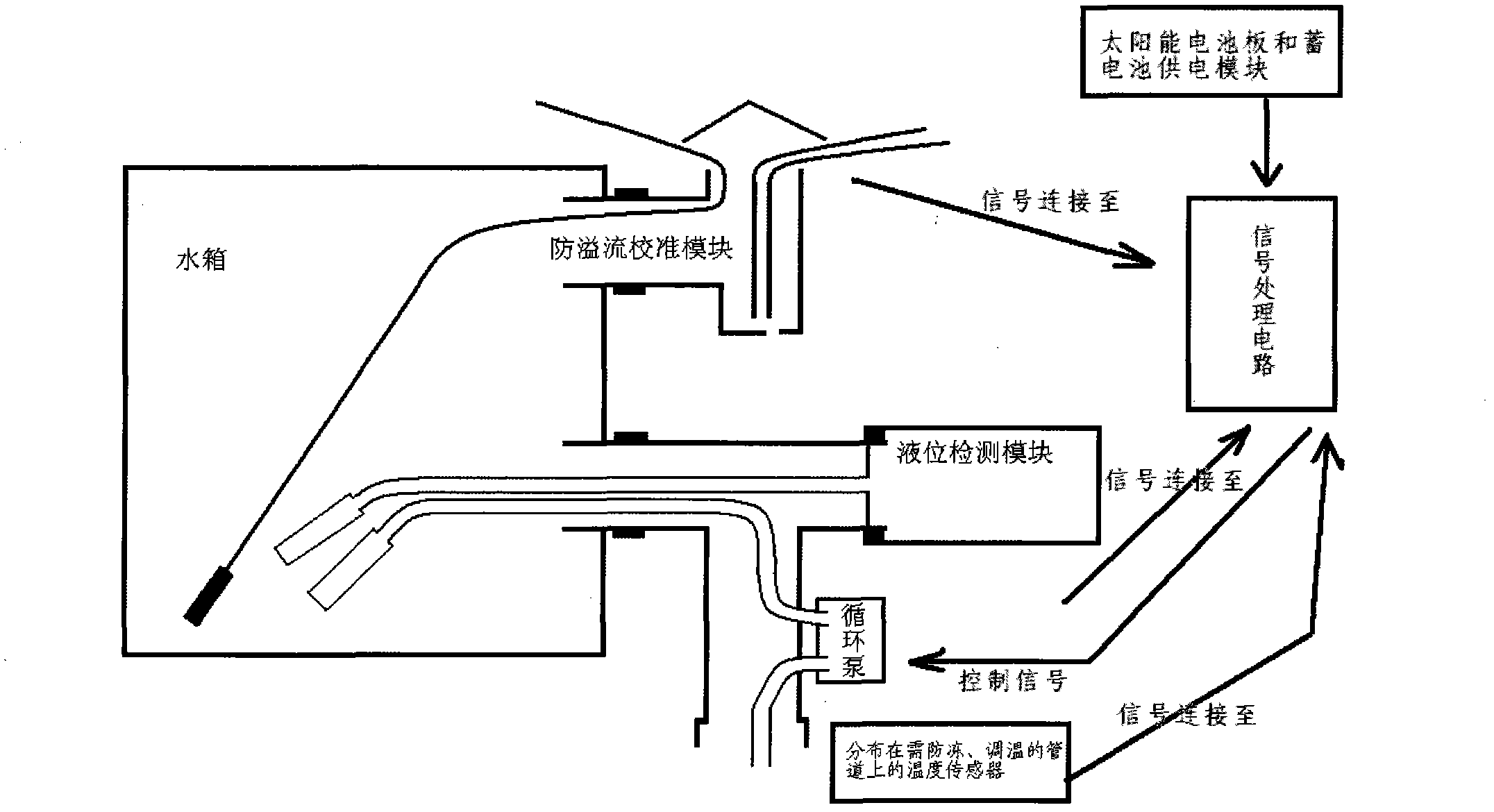

System for monitoring liquid temperature and liquid level

A measurement and control system, liquid level detection technology, applied in the direction of liquid level indicator for physical variable measurement, etc., can solve the problems of wrong measurement results, short service life, drift error, etc., achieve high-precision liquid level measurement, ensure service life, Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

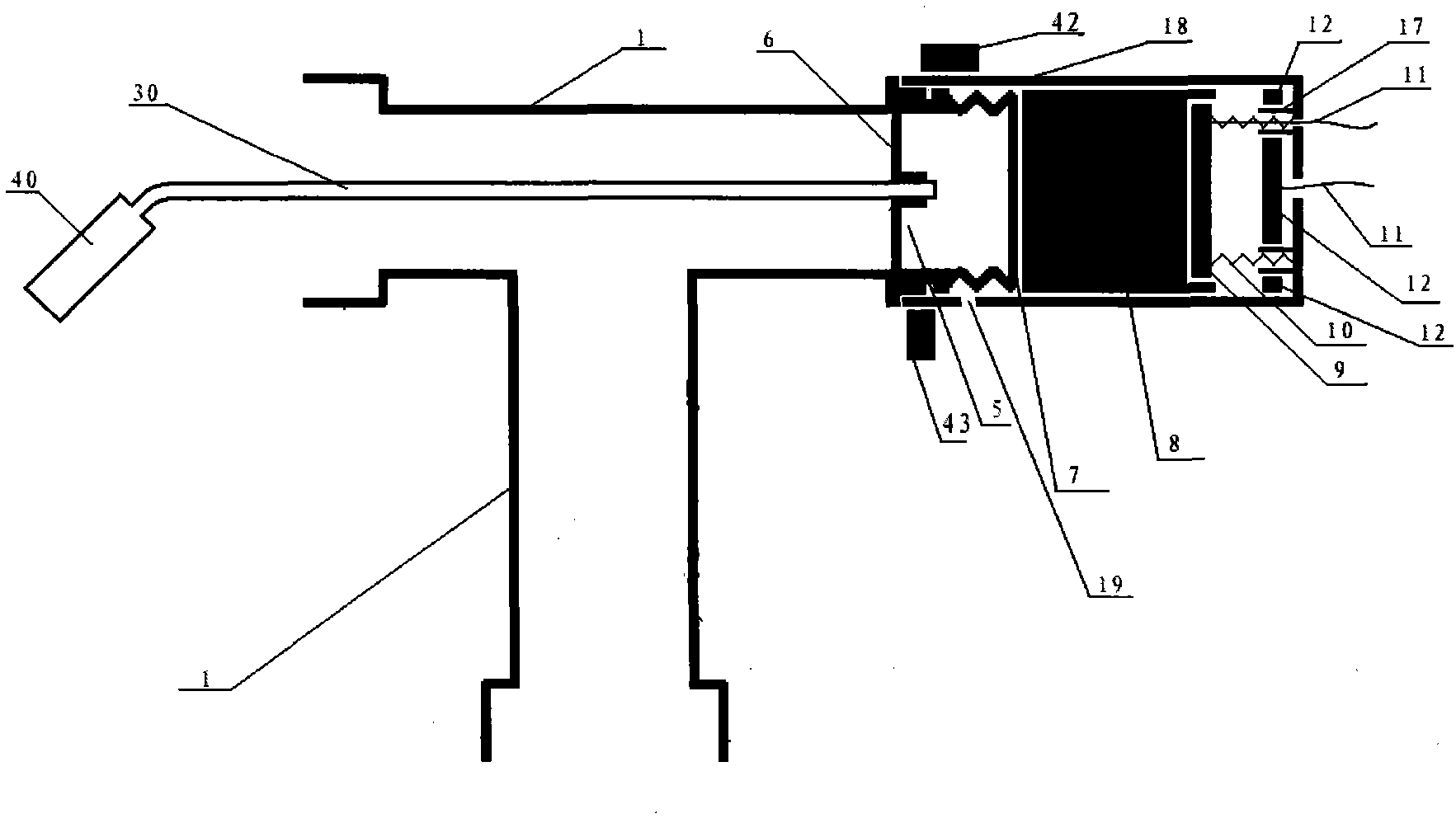

[0050] refer to figure 2

[0051] The liquid temperature and liquid level measurement and control system includes a main pipeline 1 connected to a water tank that needs to detect the liquid level, a liquid level detection module fixedly connected to the main pipeline 1, and a partition that prevents the liquid in the main pipeline from entering the liquid level detection module. Plate 6, and the pressure transmission tube 30 that transmits the pressure generated by the rise of the liquid level to the liquid level detection module; the front end of the pressure transmission tube 30 is immersed in the water tank, and the pressure transmission tube 30 is sealed with the partition plate 6 connect;

[0052] The liquid level detection module includes a casing 18 fixed at one end of the main pipe 1, and the casing 18 is provided with a deformable membrane 7 and a capacitor assembly, and the deformable membrane 7 is covered on the rear open end of the telescopic tube 7A. , the fron...

Embodiment 2

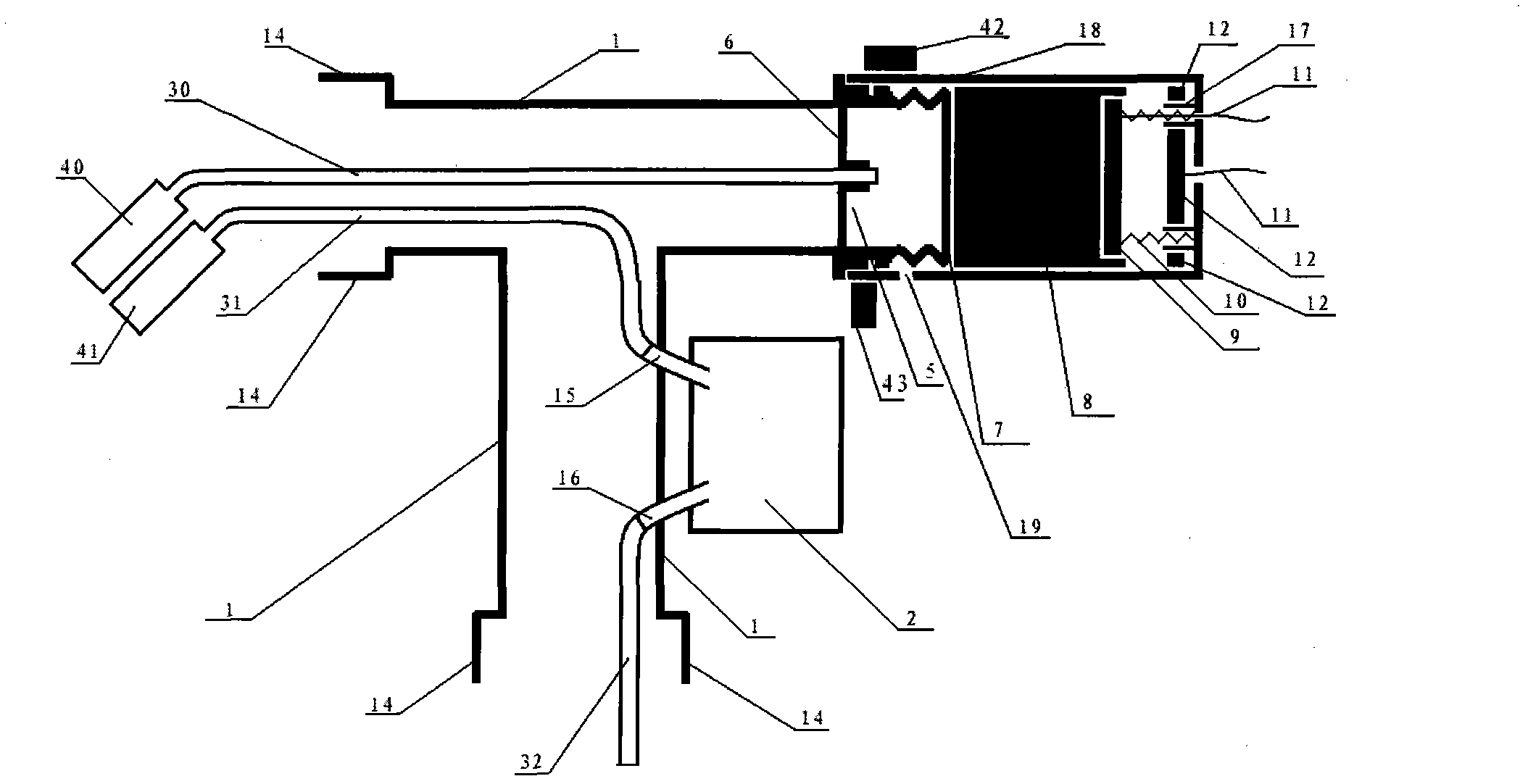

[0065] refer to image 3

[0066] This embodiment adds the following features on the basis of Embodiment 1: the water tank is a hot water tank, the main pipeline 1 has a branch pipe 1A, and the branch pipe 1A is connected to the water pipeline that needs antifreeze connection, the branch branch pipe 1A is connected to the circulation pump 2, the water inlet 15 and the water outlet 16 of the circulation pump 2 are respectively connected to the first hose 31 and the second hose 32, and the first soft hose The pipe 31 is immersed in the hot water tank, and the second hose 32 is connected to the water delivery pipeline.

[0067] There are multiple pipeline temperature sensors on the water delivery pipeline. When the temperature measured by the pipeline temperature sensors is lower than the low temperature threshold, the circulation pump 2 will make the first hose 31 draw hot water from the hot water tank, and then the second hose 31 will draw hot water from the hot water tank. 3...

Embodiment 3

[0074] refer to Figure 4-6

[0075] This implementation adds the following features on the basis of Embodiment 1: the liquid temperature and liquid level measurement and control system also includes an anti-overflow calibration module installed on the overflow port of the water tank, and the described anti-overflow calibration module includes a calibration module that is compatible with the water tank The overflow casing 3 connected to the overflow port, and two sensor electrodes 24 placed in parallel in the overflow casing 3, there is a gap between the two sensor electrodes 24; the overflow casing 3 is formed by a pipe joint 14 Composed of a water storage tank 25, the upper end of the water storage tank 25 is open 26 to allow the liquid to overflow, the sensor electrode 24 is close to the bottom of the water storage tank 25, when the water in the water storage tank 25 has not passed the sensor electrode 24 , the sensor electrode 24 sends an overflow signal to the signal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com