Flame retardant expanded double-sided tape and preparation process thereof

A double-sided adhesive tape and preparation technology, which is applied in the direction of adhesives, film/sheet adhesives, pressure-sensitive films/sheets, etc., can solve the problems of inability to securely fix batteries, unstable expansion tapes, and high expansion rates. Achieve the effects of excellent flame retardant safety performance, excellent bond strength, and excellent expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] A flame-retardant expansion double-sided adhesive tape, which sequentially includes a first composite acrylic adhesive layer, a flame-retardant polystyrene synthetic resin layer, a second composite acrylic adhesive layer and a double-sided release film layer from top to bottom;

[0032] The first composite acrylic adhesive layer and the second composite acrylic layer are formed by mixing acrylic acid and styrene, and a small amount of curing agent is added thereto, and the curing agent can be isocyanate.

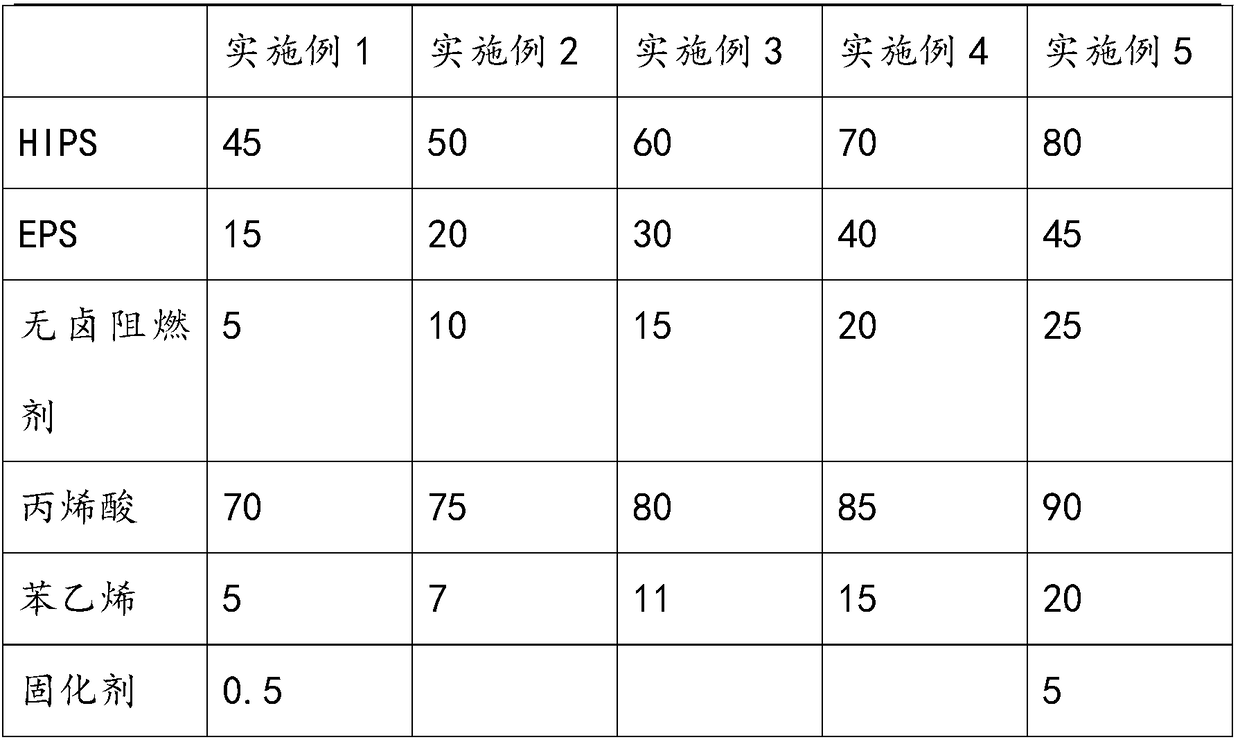

[0033] Among them, the proportion of acrylic acid and styrene in the composite acrylic adhesive layer is 70-90:5-20; the proportion of HIPS, EPS and halogen-free flame retardant in the flame-retardant polystyrene synthetic resin layer is 45-80:15- 45:5-25, organic nitrogen-phosphorus flame retardants and inorganic nitrogen-phosphorus flame retardants can be used for halogen-free flame retardants.

[0034] The composition of each substance in Example 1-Example 5 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com