Conductive rubber shoe sponge insole cloth scraping rubber cement and preparation method and application thereof

A technology of conductive rubber shoes and bottom cloth, which is applied in the field of conductive rubber shoe sponge midsole cloth scraping glue and its preparation, achieving the effects of good bonding strength, simple production process, and improved production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

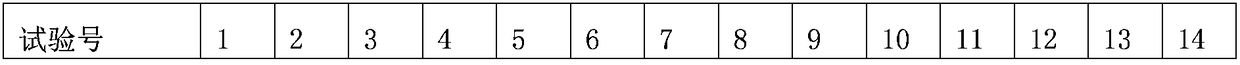

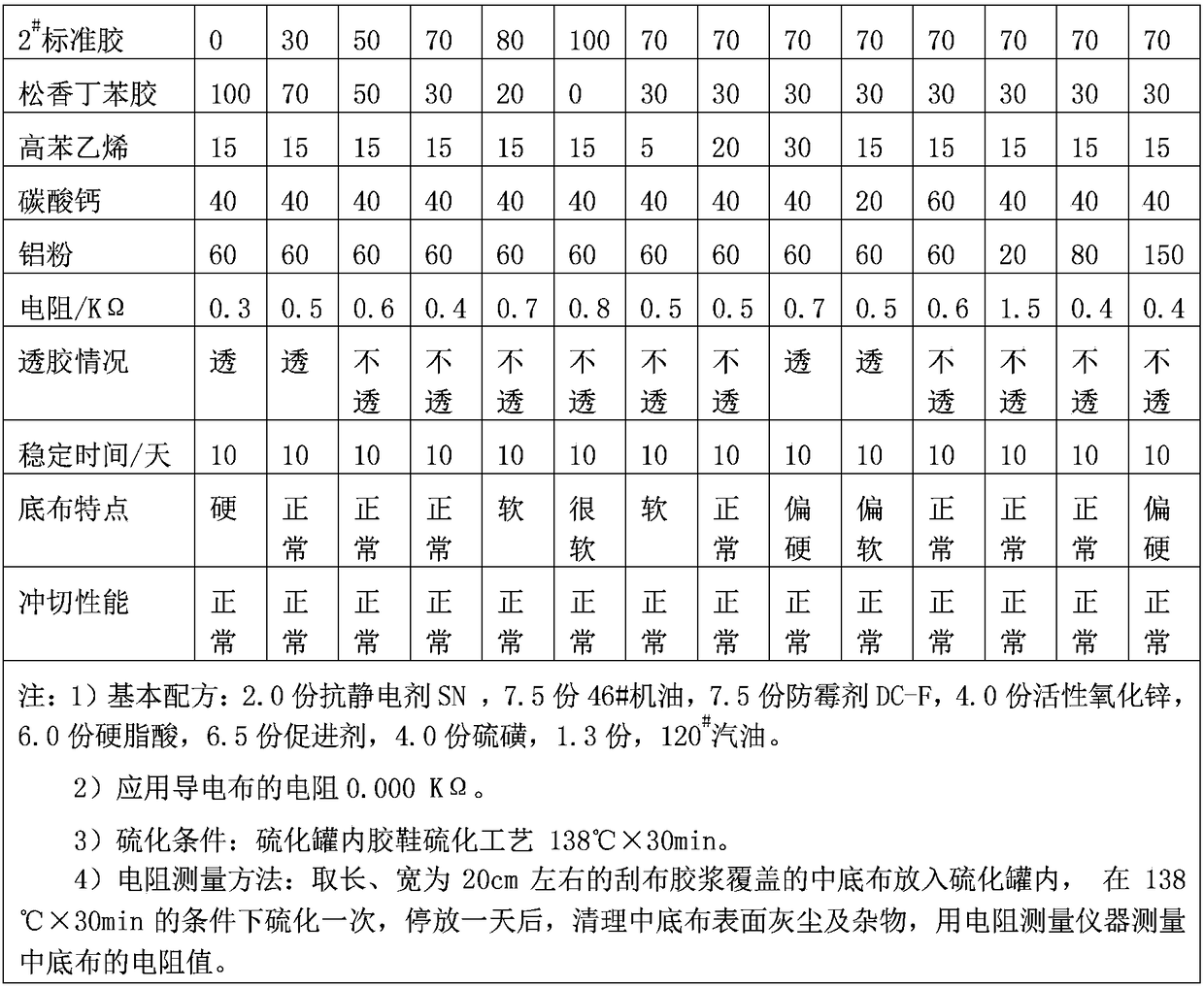

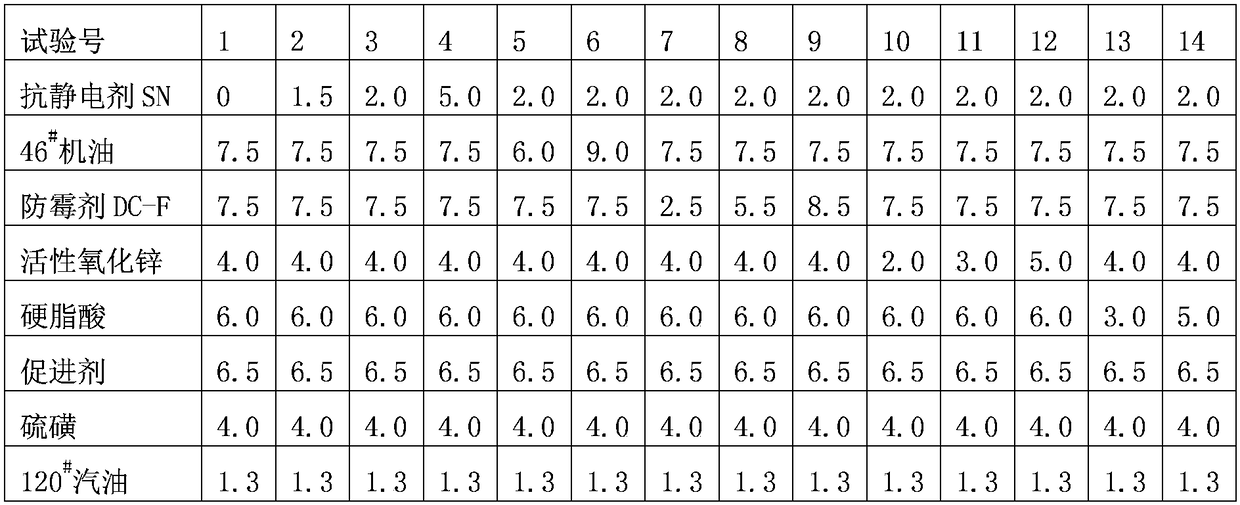

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 of the present invention: conductive rubber shoes sponge midsole cloth scraping cloth mucilage, calculated in parts by weight, including 70 parts 2 # Standard glue, 30 parts of rosin styrene-butadiene rubber, 15 parts of high styrene, 40 parts of calcium carbonate, 60 parts of aluminum powder, 7.5 parts of engine oil, 7.5 parts of antifungal agent DC-F, 4.0 parts of active zinc oxide, 6.0 parts of stearic acid , 2.0 parts of antistatic agent, 6.5 parts of accelerator, 4.0 parts of sulfur, the mass ratio of rubber to gasoline: 1:1.3.

[0045] The preparation method of cloth scraping glue for midsole cloth of conductive rubber shoes sponge:

[0046] 1) Making the midsole glue and plasticizing rubber: put 2# standard rubber and rosin-styrene-butadiene rubber in the internal mixer for 1-2 minutes, then add high styrene, after pressing for 5-7 minutes, lift the top bolt to make the glue The material is turned over, and the material is discharged after continuou...

Embodiment 2

[0050] Embodiment 2 of the present invention: calculated in parts by weight, including 70 parts of 2 # Standard glue, 30 parts of rosin styrene-butadiene rubber, 15 parts of high styrene, 40 parts of calcium carbonate, 100 parts of aluminum powder, 2.0 parts of antistatic agent SN, 7.5 parts of engine oil, 7.5 parts of antifungal agent DC-F, 4.0 parts of active oxidation Zinc, 6.0 parts of stearic acid, 6.5 parts of accelerator, 4.0 parts of sulfur, rubber to gasoline ratio: 1.3 parts.

[0051] The preparation method and application are the same as in Example 1.

Embodiment 3

[0052] Embodiment 3 of the present invention: calculated in parts by weight, including 70 parts of 2 # Standard glue, 30 parts of rosin styrene-butadiene rubber, 15 parts of high styrene, 40 parts of calcium carbonate, 60 parts of aluminum powder, 5.0 parts of antistatic agent SN, 7.5 parts of engine oil, 7.5 parts of antifungal agent DC-F, 4.0 parts of active oxidation Zinc, 6.0 parts of stearic acid, 6.5 parts of accelerator, 4.0 parts of sulfur, rubber to gasoline ratio: 1.3 parts.

[0053] The preparation method and application are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com