Coextruded jacket for flame retardant fiber optic cables

A fiber optic cable and cable sheath technology, applied in the direction of insulated cables, cables, optics, etc., can solve problems such as sheath cracking, achieve excellent bonding strength, eliminate outer layer wrinkling and/or separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Before turning to the following detailed description and accompanying drawings, which illustrate exemplary embodiments, it is to be understood that the inventive technology is not limited to the details or methodology set forth in the detailed description or shown in the drawings. For example, features and attributes associated with an embodiment shown in one of the drawings or described in text related to one of the embodiments would apply to the ones in the drawings, as will be understood by those of ordinary skill in the art Other embodiments are shown in another and / or described elsewhere in the text.

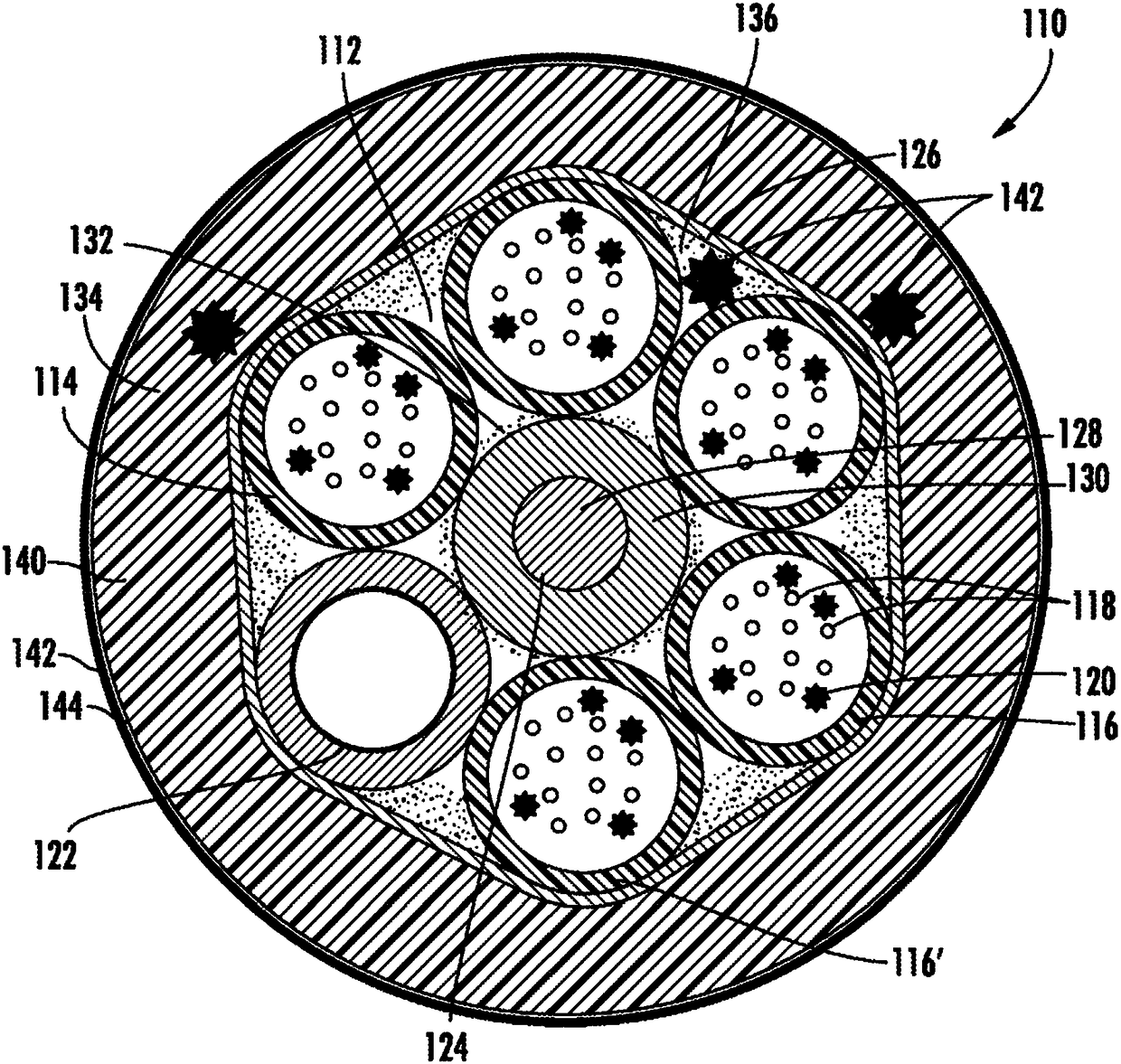

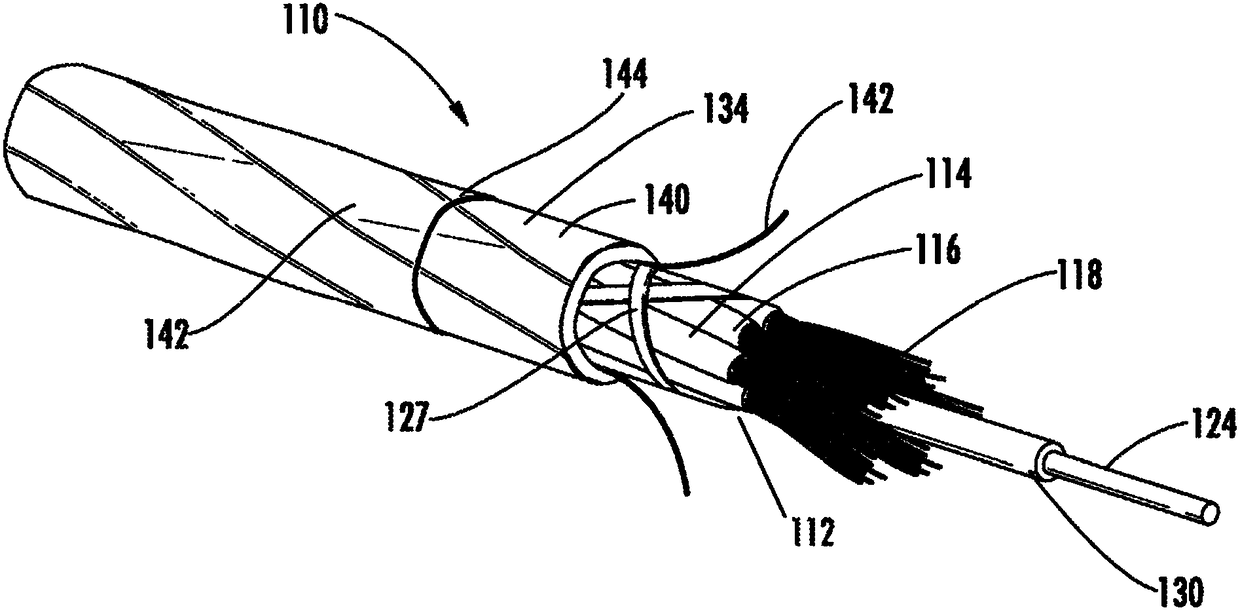

[0018] refer to figure 1 , the cable in the form of a fiber optic cable 110 may be an external device loose tube cable, an indoor cable with fire / flame retardant properties, an indoor / outdoor cable, or another type of cable (such as a hybrid with micromodules or including conductive elements) fiber optic cables for data center interconnect cables). According to an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com