Preparation device of porous microspheres and method thereof

A technology for porous microspheres and preparation devices, which is applied in the fields of microsphere preparation, microcapsule preparations, chemical instruments and methods, etc., can solve the problem of increasing the surface roughness of microspheres, reducing the oil-water interfacial tension, and weakening the driving force of droplet sphericity, etc. problems, to achieve the effect of improving the generation rate and pass rate, easy control, and enhancing thermal stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A further detailed description is carried out below in conjunction with the description of the accompanying drawings:

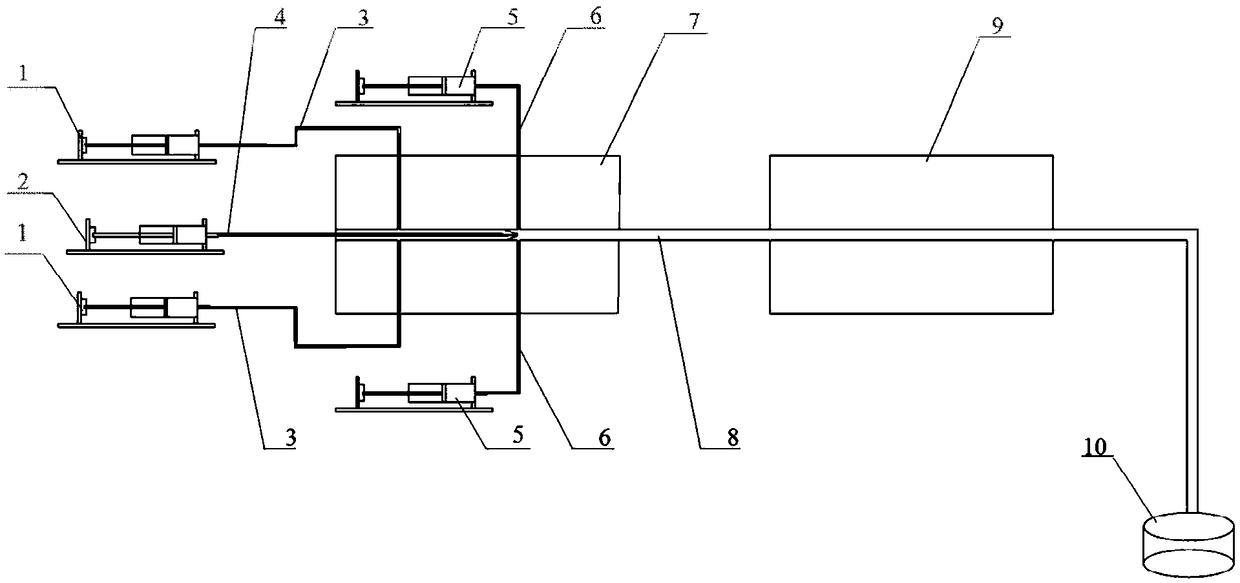

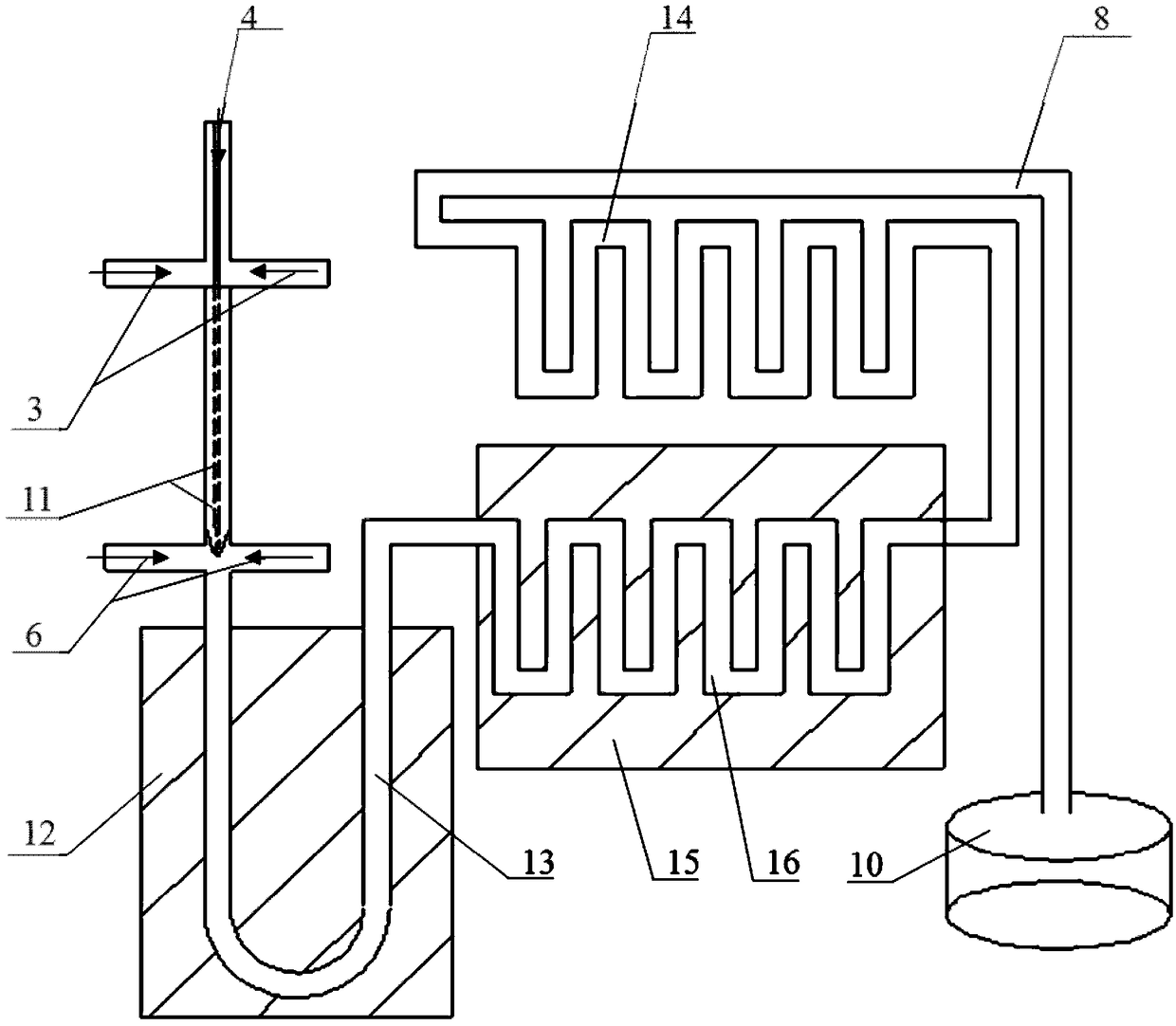

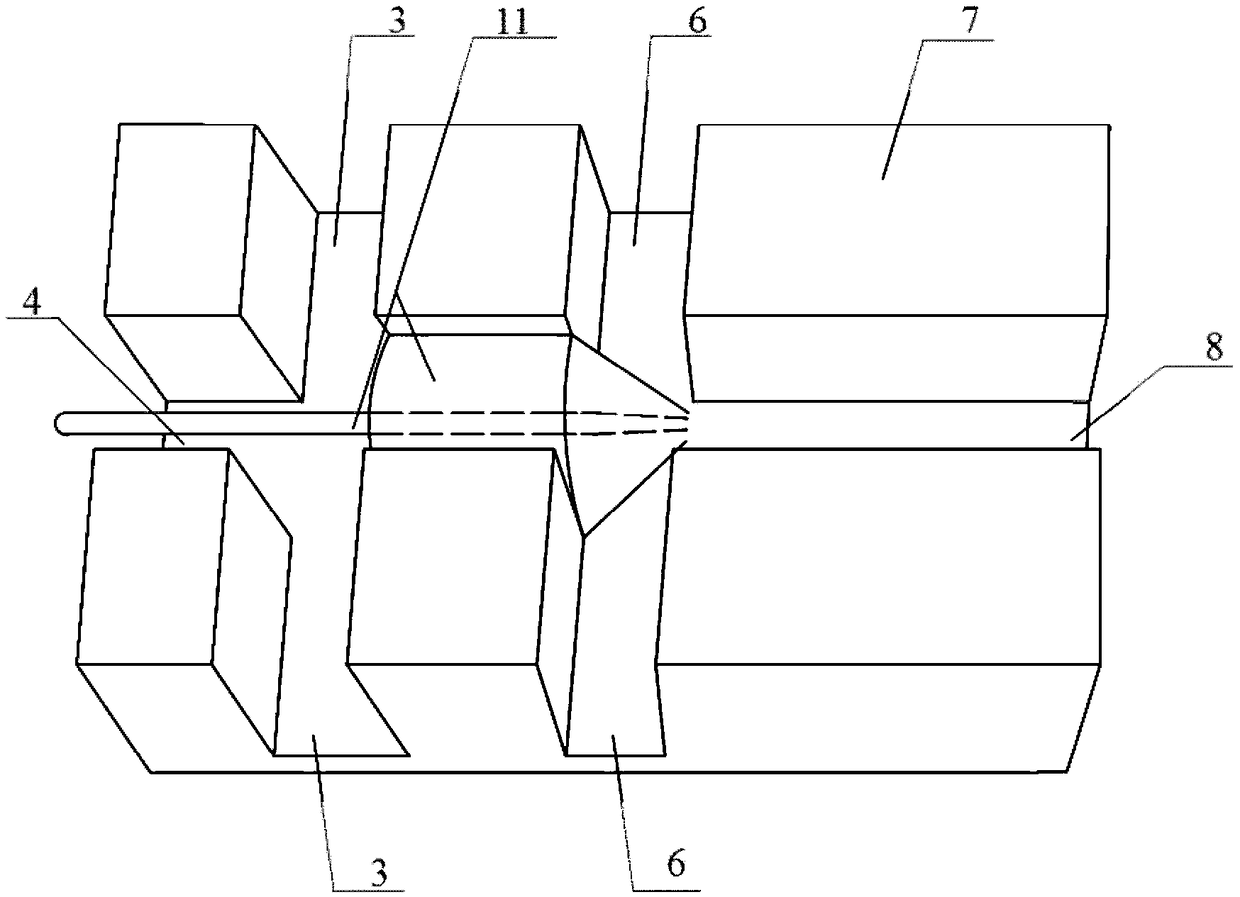

[0031] figure 1 The system diagram of the present invention is given, and the specific structure includes an intermediate fluid injection pump and a syringe 1, an internal phase fluid injection pump and a syringe 2, an intermediate phase input channel 3, an internal phase input channel 4, an external phase fluid injection pump and a syringe 5, External phase input channel 6, microfluidic chip 7, main flow channel 8, ultraviolet irradiation chamber 9, porous microsphere collector 10 and other main components. Intermediate phase fluid injection pump and syringe 1, internal phase fluid injection pump and syringe 2, external phase fluid injection pump and syringe 5 respectively drive the intermediate phase fluid, internal phase fluid, and external phase fluid from the intermediate phase input channel 3, internal phase input channel 4, The external phase i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com