Polymercaptan curing agent, and preparation method and application thereof

A technology of curing agent and polythiol, which is applied in the field of polythiol curing agent and its preparation, can solve the problems of high chloride ion content, high requirement fields, unusable transparency and other problems, and achieve low halogen content and good Conversion rate, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

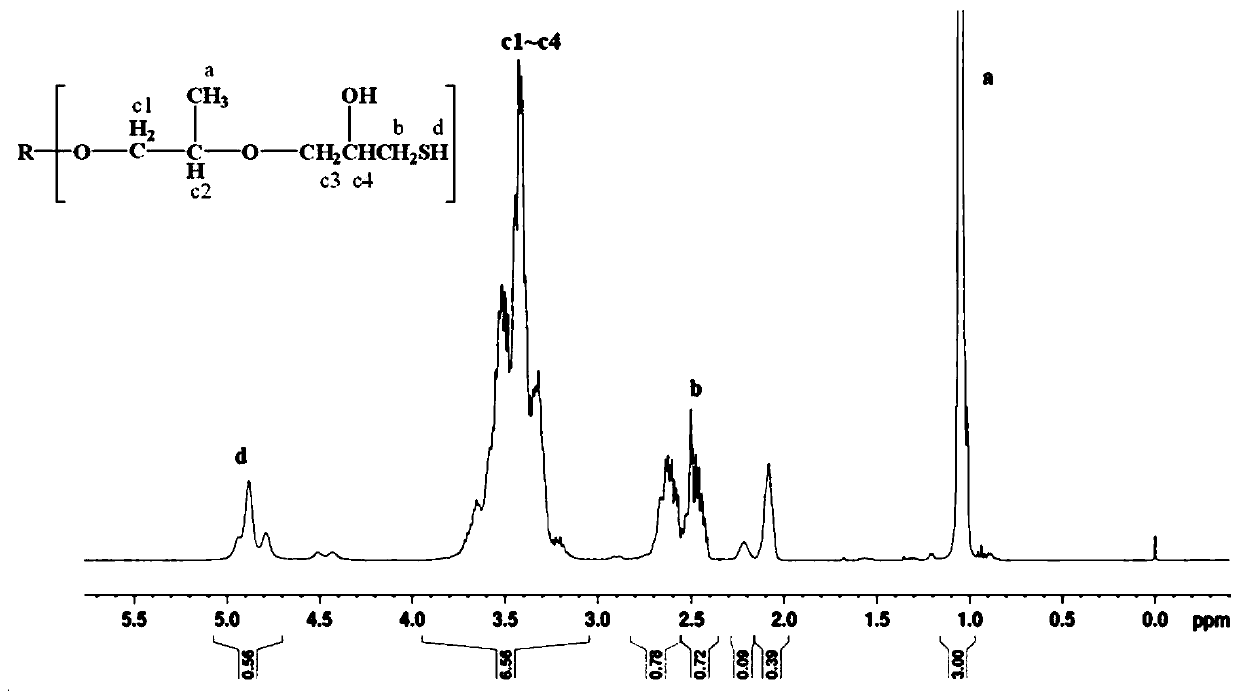

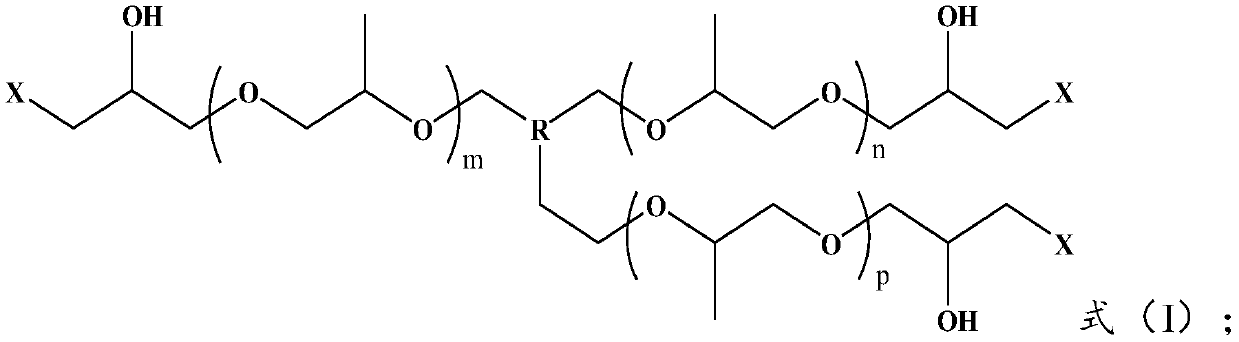

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of polymercaptan curing agent, comprises the following steps:

[0032] a) NaSH, phase transfer catalyst, organic polyhalogenated polyether and water in H 2 React in the presence of S to obtain a crude product; the iron content of the NaSH is 0.005wt% to 1wt%;

[0033] b) washing and drying the crude product obtained in step a) successively to obtain a polythiol curing agent.

[0034] The present invention at first NaSH, phase transfer catalyst, organic polyhalogenated polyether and water in H 2 The reaction was carried out in the presence of S to obtain the crude product. In the present invention, the iron content of the NaSH is 0.005wt%-1wt%, preferably 0.06wt%-0.9wt%. The present invention does not have special restriction to the source of described NaSH, can adopt commercially available commodity or self-produced (mainly prepare by introducing hydrogen sulfide into alkali solution) well-known to those skilled in ...

Embodiment 1

[0073] (1) Adding 198.3g mass fraction is 32% NaSH (iron content is 0.08wt%) aqueous solution and 13.3g phase transfer catalyst tetrabutylammonium bisulfate in reactor, then adds 177.7g chlorinated polyether and 132g to Ionized water, check the airtightness after closing the reactor, and then inject H into the reactor 2 S gas keeps the inside of the kettle at normal pressure, heats the reaction system to 90°C through an oil bath, and then keeps it warm for 6 hours, then opens the vent valve of the reactor and uses N 2 After replacement, the product was left to stand and separated to obtain the crude product A.

[0074] (2) Add the crude product A into 180g deionized water to wash once, adjust the pH of the organic phase to 5-7 with hydrochloric acid, let it stand for stratification after stabilization, and take out the lower layer material to be the crude product B; Add 180g of deionized water, mix well and let it stand for 12 hours, then cut out the product and remove water ...

Embodiment 2

[0077] The preparation method provided in Example 1 was used to obtain a polythiol curing agent; the difference was that the iron content of NaSH was 0.06 wt%.

[0078]The product obtained by the preparation method provided in Example 2 of the present invention is colorless and transparent, with a chromaticity (Hazen) of 18 when tested by a Hunter chromaticity meter, and a halogen (Cl) content of 326 ppm when tested by a coulometric chlorine meter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com