Manufacturing method of cellulose resin compositions

A technology of resin composition and manufacturing method, which is applied in the field of manufacturing cellulose-based resin compositions, can solve the problems of reduced corn production, cellulose-based resins are not resistant to impact, and insufficient flow, and achieve excellent mixing performance and promote The effect of uniform mixing and preventing the remaining of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

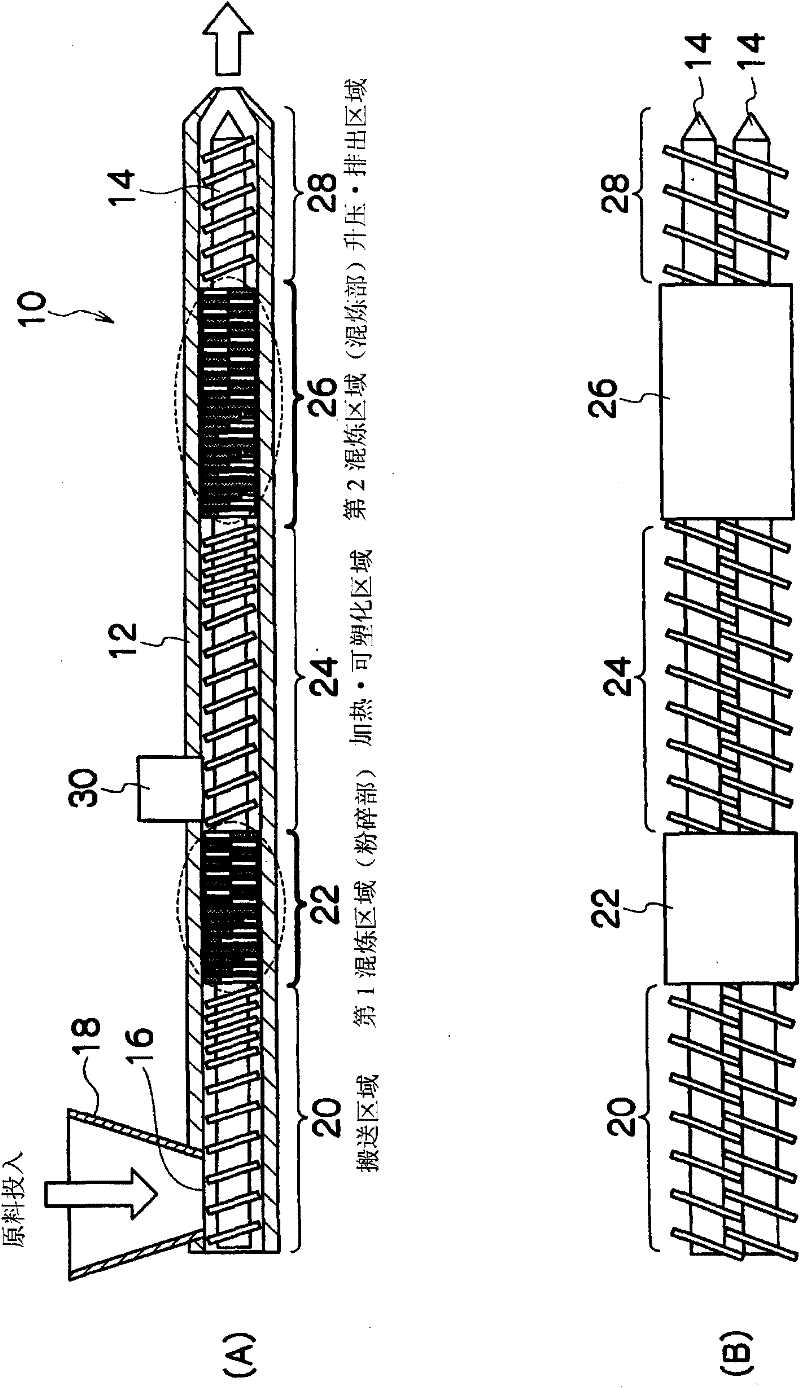

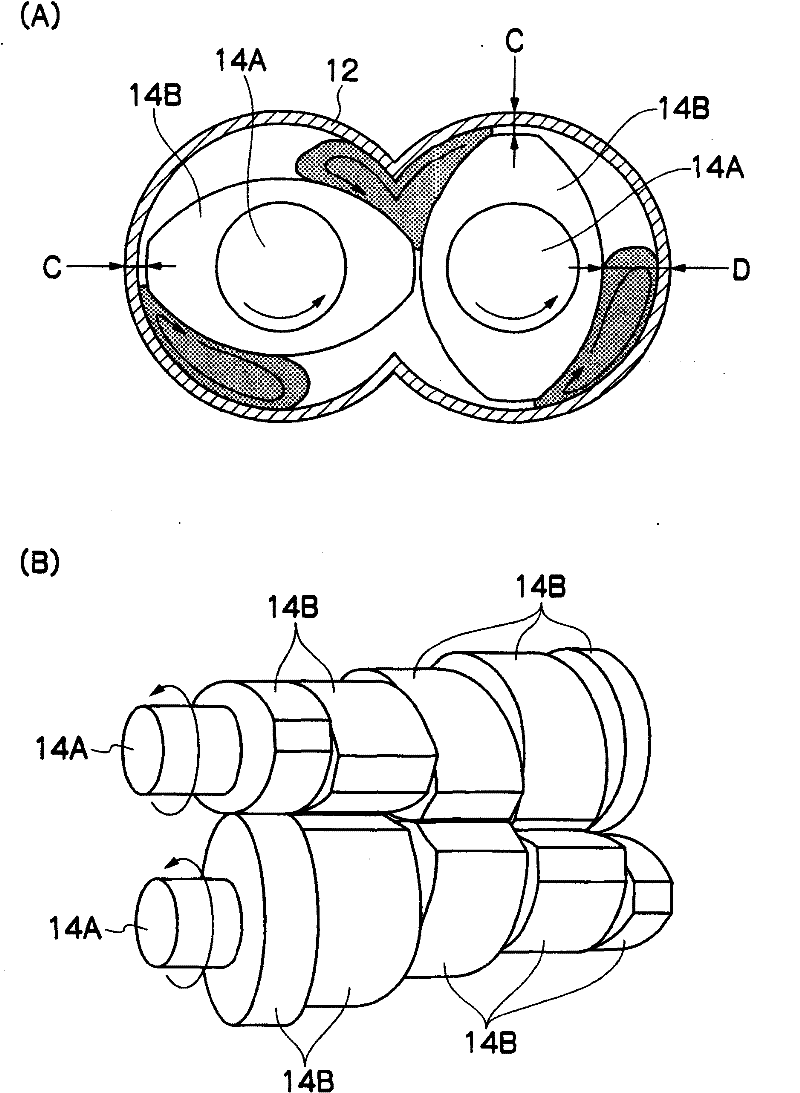

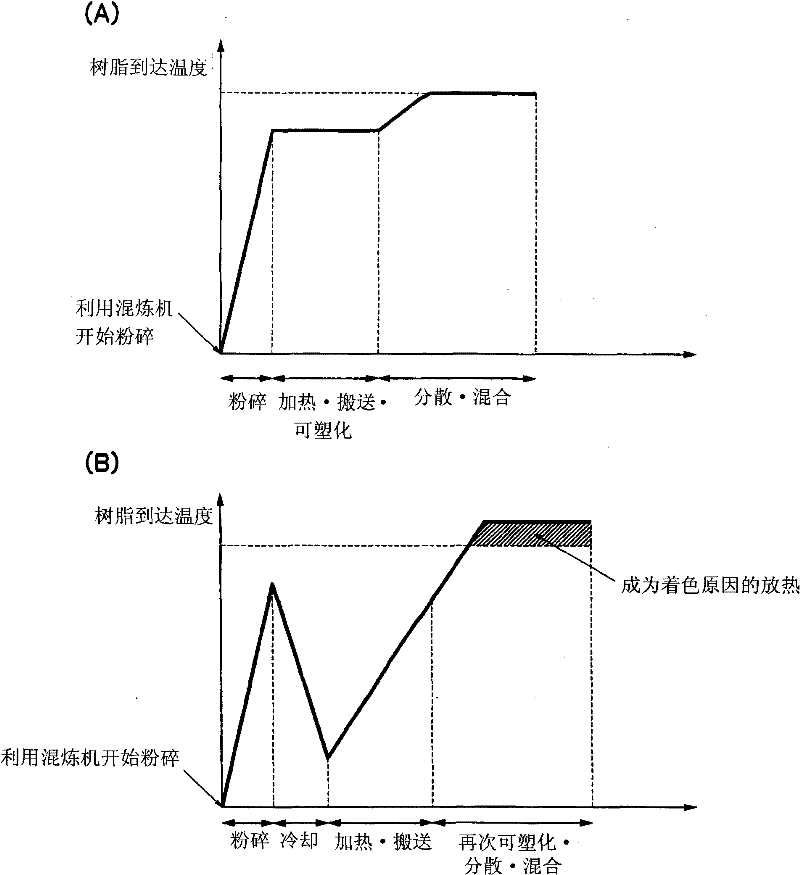

Method used

Image

Examples

Embodiment 1

[0070] Next, what kind of physical properties and state can be achieved for the manufactured cellulose-based resin composition (hereinafter referred to as the composition) by the examples satisfying the production method of the cellulose-based resin composition of the present invention and the comparative example not satisfied? test to a certain extent. In addition, the test was carried out as follows: a drawing die was installed at the outlet of the kneader, and the linear (rod-shaped) composition extruded from the drawing die was cooled and sheared to produce pellets.

[0071] [raw material]

[0072] Diacetyl cellulose (L-70: manufactured by Daicel Chemical Co., Ltd.) was used as the cellulose-based resin, and polycarbonate (A1700: manufactured by Idemitsu Petrochemical Co., Ltd.) was used as the petroleum-based resin. As a plasticizer, either trimethyl phosphate (manufactured by Daihachi Chemical Co., Ltd.) or diethylene glycol dibenzoate (Rikaflo L A100: manufactured by S...

Embodiment 2

[0077] Example 2 was carried out in the same manner as Example 1 except that only the plasticizer was changed from trimethyl phosphate to diethylene glycol dibenzoate. That is, the influence of changing the plasticizer was examined. The temperature of the resin discharged from the discharge port of the wire drawing die in Example 2 was 262°C.

Embodiment 3

[0079] In Example 3, the raw material composition was such that diacetyl cellulose was 35% by mass, polycarbonate was 50% by mass, and diethylene glycol dibenzoate was 15% by mass. As the conditions of the kneader (twin-shaft kneader 10), except that the shear rate is set to 140 to 436 sec that satisfies the present invention -1 436sec of upper limit -1 Other than that, it carried out similarly to Example 1. The temperature of the resin discharged from the discharge port of the wire drawing die in Example 3 was 270°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Charpy impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com