LED light source packaged with thin-wall ceramic lens

An LED light source and LED chip technology, applied in electrical components, electric solid state devices, circuits, etc., can solve the problems of poor light source quality and affect the normal use of light sources, and achieve the effect of avoiding blue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above content has fully described the present invention, and the implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation of the present invention is not limited thereto.

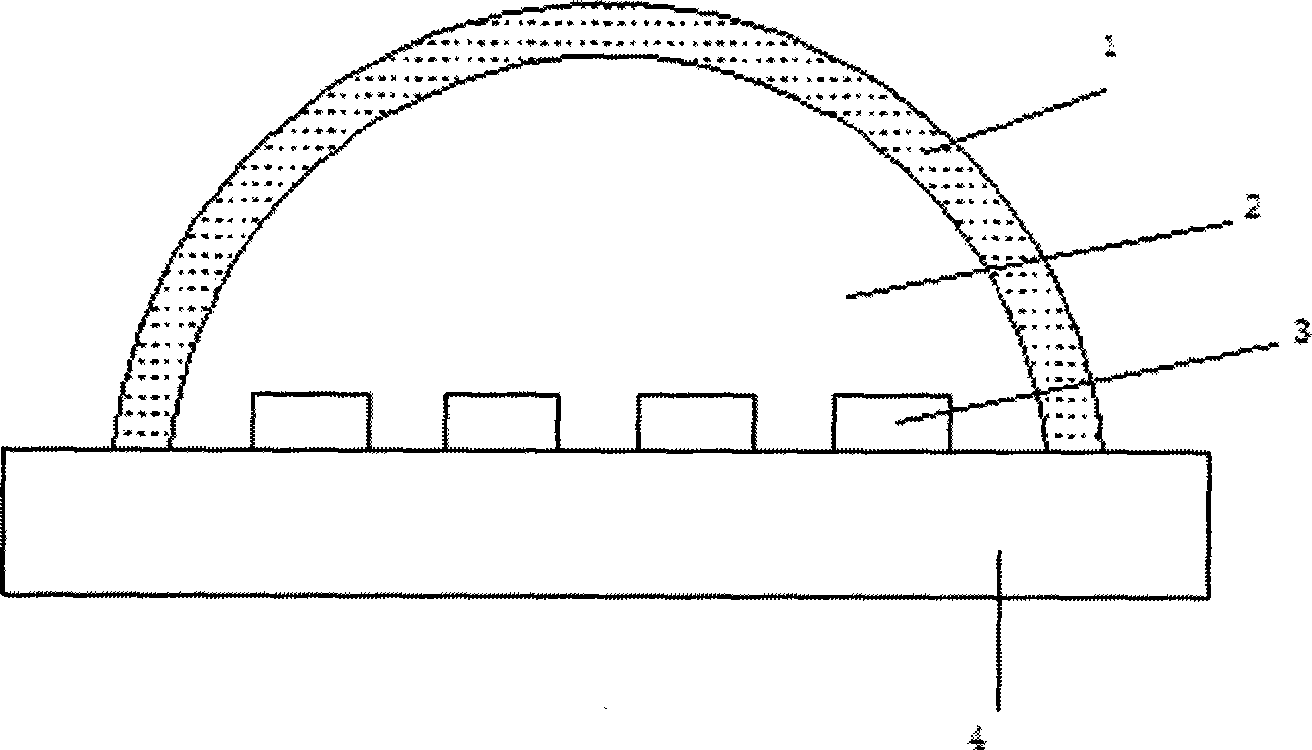

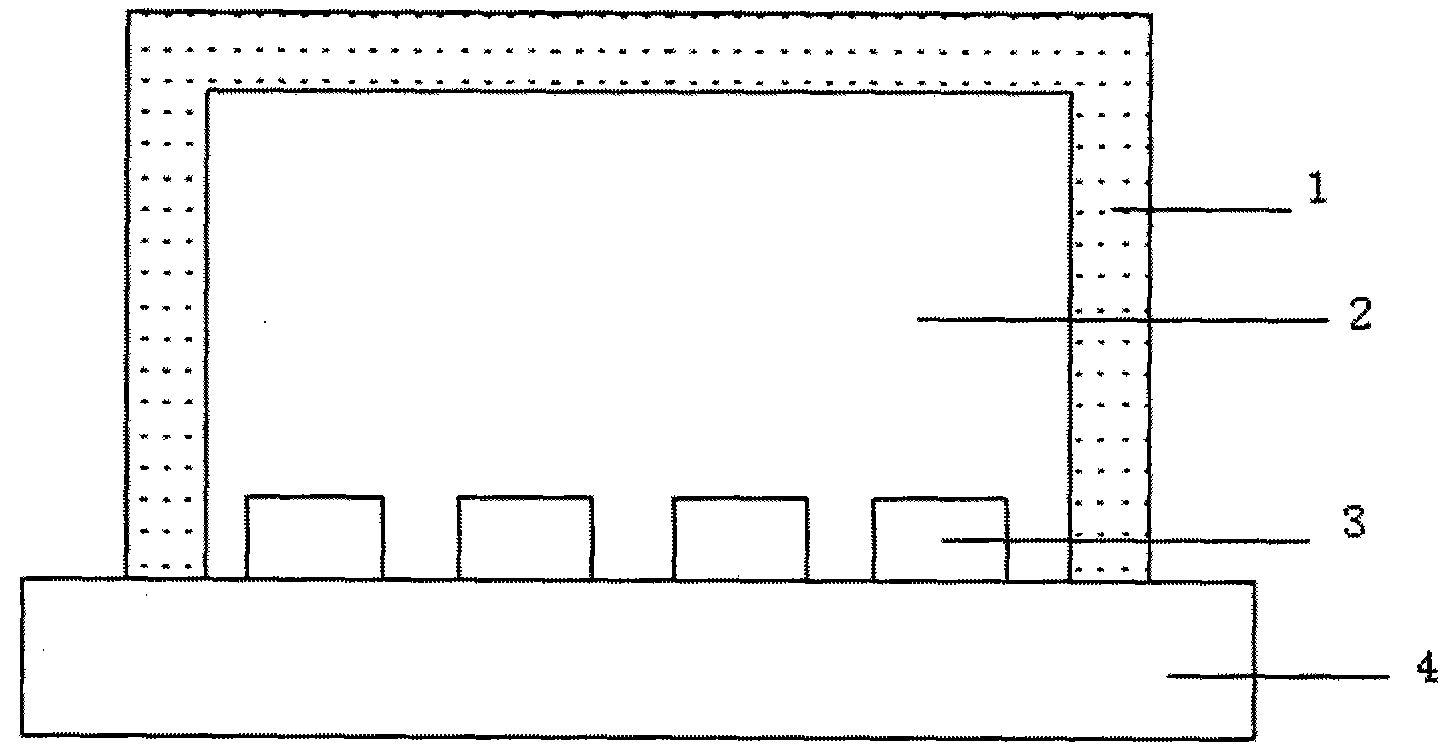

[0020] refer to Figure 1 to Figure 2 , is only a preferred embodiment of an LED light source packaged with a thin-walled ceramic lens in the present invention. The thin-walled ceramic lenses are respectively in the shape of a hollow hemisphere and a hollow box.

[0021] Sinter the thin-walled lens-type ceramic blank obtained by injection molding, dry pressing molding, gel injection molding, extrusion molding, slip casting or tape casting at high temperature at 1000-1900 °C, and then at 800 °C Annealing at -1700°C to obtain thin-walled transparent ceramics. The ceramic transmittance reaches the theoretical transmittance without post-processing.

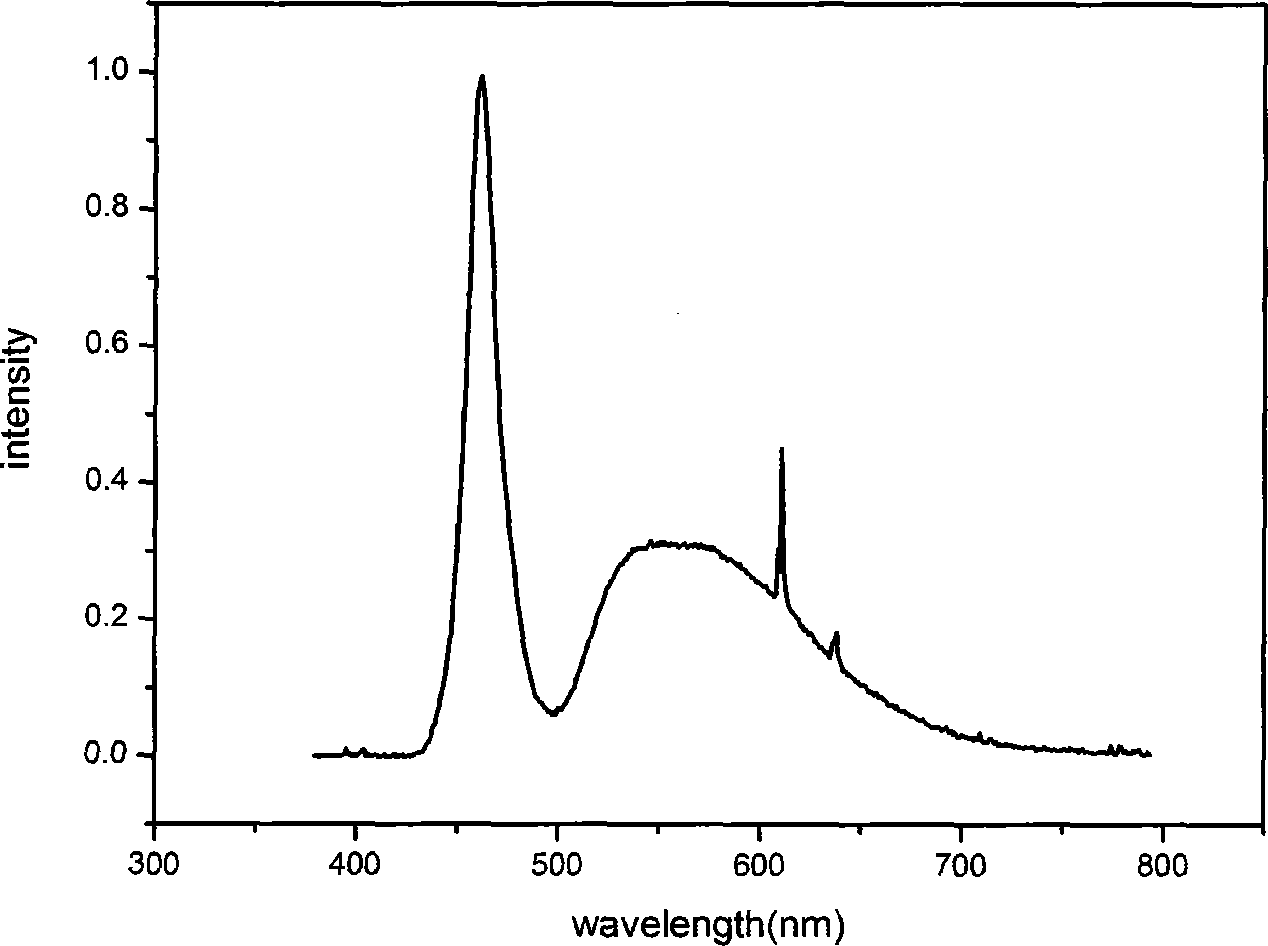

[0022] In this example, an LED light source packaged by a thin-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com