Flexible automatic production system for combined firework

A technology that combines fireworks and production systems. It is applied in the directions of fireworks, offensive equipment, and weapon types. It can solve problems such as unsafe hidden dangers, and achieve the effect of avoiding time-consuming and laborious, fast loading, and avoiding poor accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

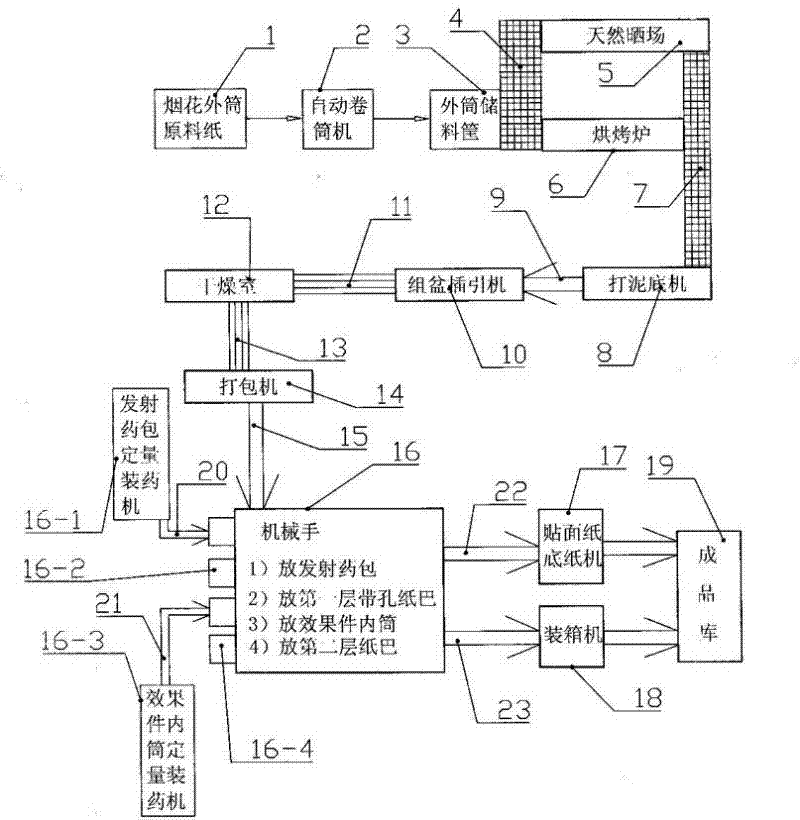

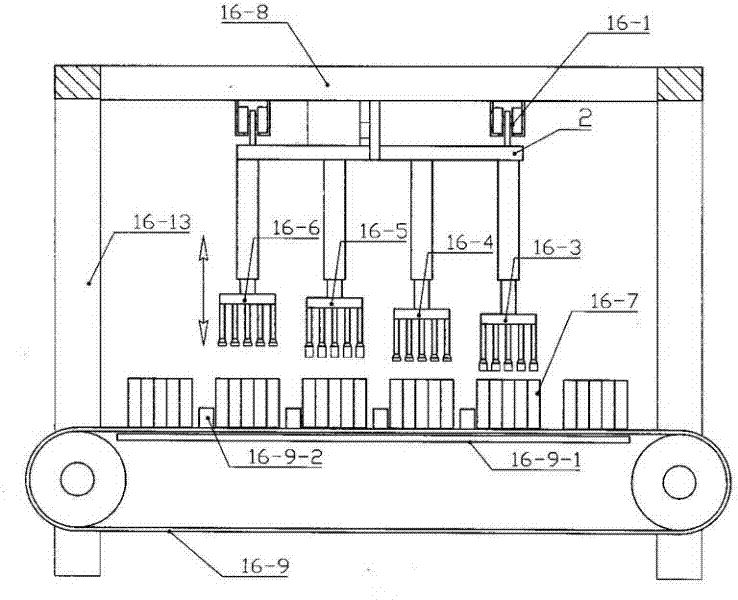

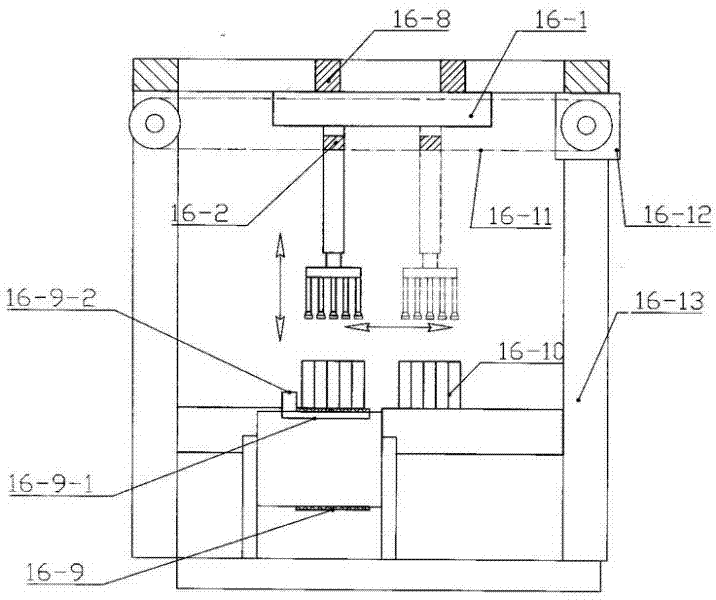

[0022] Embodiment: With reference to the accompanying drawings, the combined fireworks flexible automatic production system designed by the present invention includes the following equipment: an automatic outer cylinder machine 2, an outer cylinder storage basket 3, a hanging conveyor or a metal mesh conveyor 4, and a natural drying field 5 , Baking oven 6, Conveyor 7, Sludger 8, Belt Conveyor 9, Basin Inserting Machine 10, Metal Mesh Conveyor 11, Drying Room 12, Belt Conveyor 13, Packing Machine 14, Belt Conveyor 15, manipulator 16, veneer paper bottom paper, trademark machine 17, packing and sealing machine 18, finished product warehouse 19.

[0023]The working process of the present invention is: the system first rolls the raw material paper 1 of the outer cylinder of fireworks into a single cylinder with a diameter of 20-75mm through the automatic outer cylinder machine 2 and stores it in the storage basket of the outer cylinder 3, and then fills the single outer cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com