Push bottle mechanism

A bottle feeding and pushing plate technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of increasing equipment cost, system complexity, hindering the smooth suction of bottles, broken bottles, glass debris, etc., and achieves the effect of preventing bottle bursting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

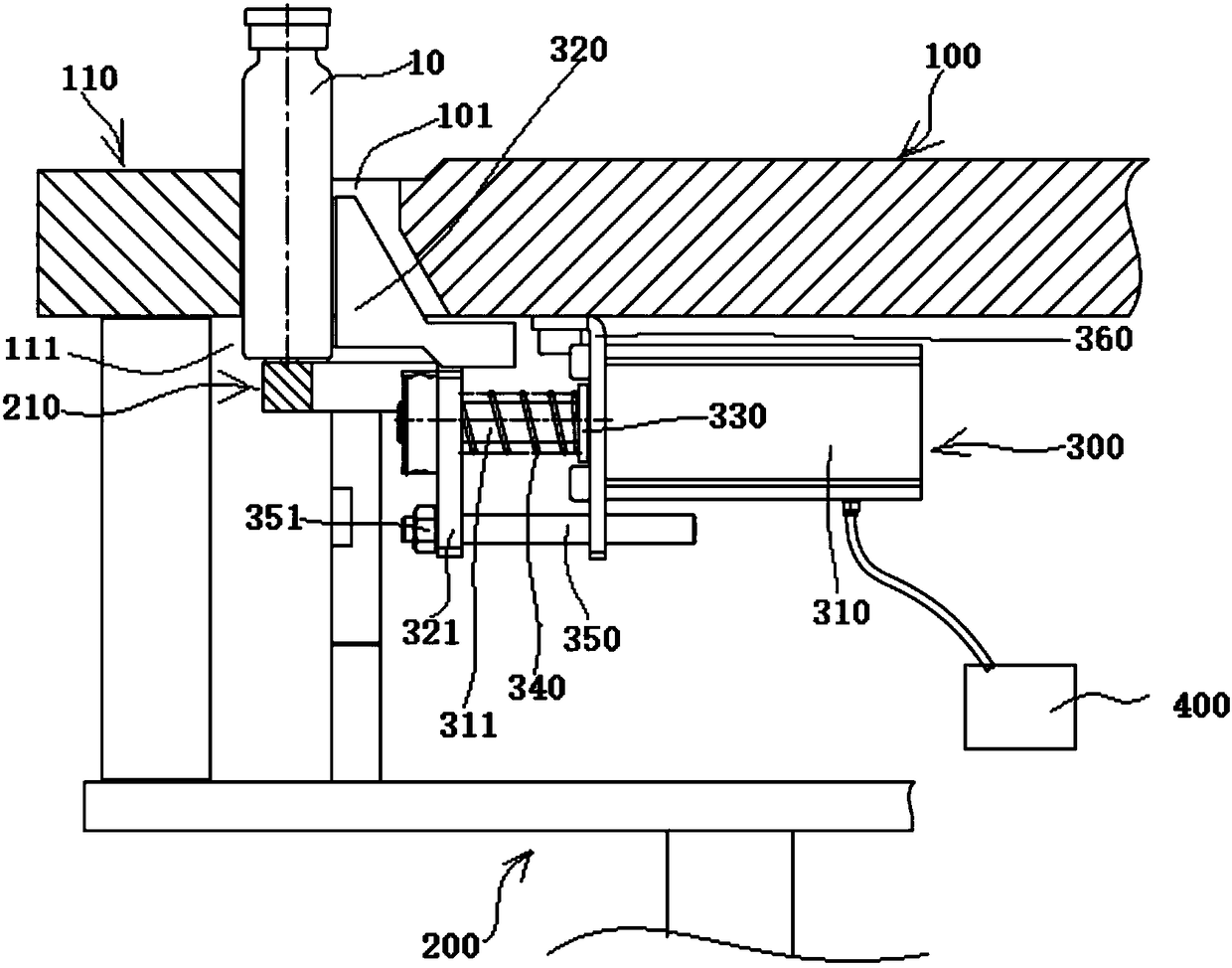

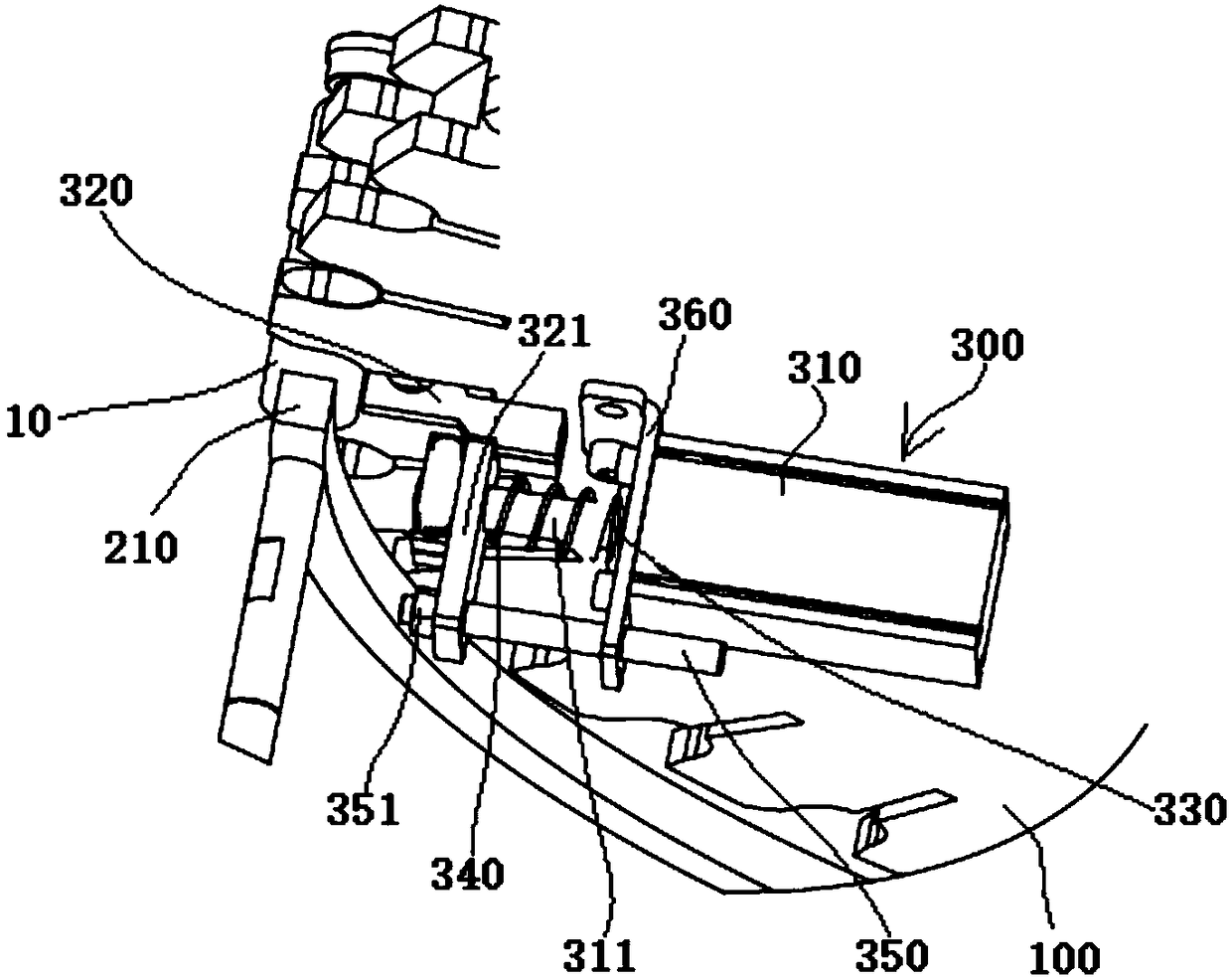

[0022] See figure 1 with figure 2 As shown in the bottle pushing mechanism, in this embodiment, the bottle pushing mechanism is arranged at the bottom of the bottle feeding star wheel 100. Of course, the bottle pushing mechanism can also be arranged at the top of the bottle feeding star wheel 100 according to the needs of use. The bottle pushing mechanism includes a pushing plate 320 movably arranged on the inner wall of the bottle feeding groove 101 of the bottle feeding star wheel 100, and a bottle supporting plate 210 is provided under the bottle feeding star wheel 100. A driving device 300 connected to the control device 400 is fixed at the bottom of the bottle feeding star wheel 100. The driving rod 311 of the driving device 300 is controlled to make the bottle 10 in the bottle feeding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com