Plant material cutting pulverizer

A pulverizer and plant material technology, which is applied to cutting equipment, grain processing, agricultural machinery and tools, etc., can solve the problems of not being able to achieve the ideal processing effect, clogging of the sieve, and affecting production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

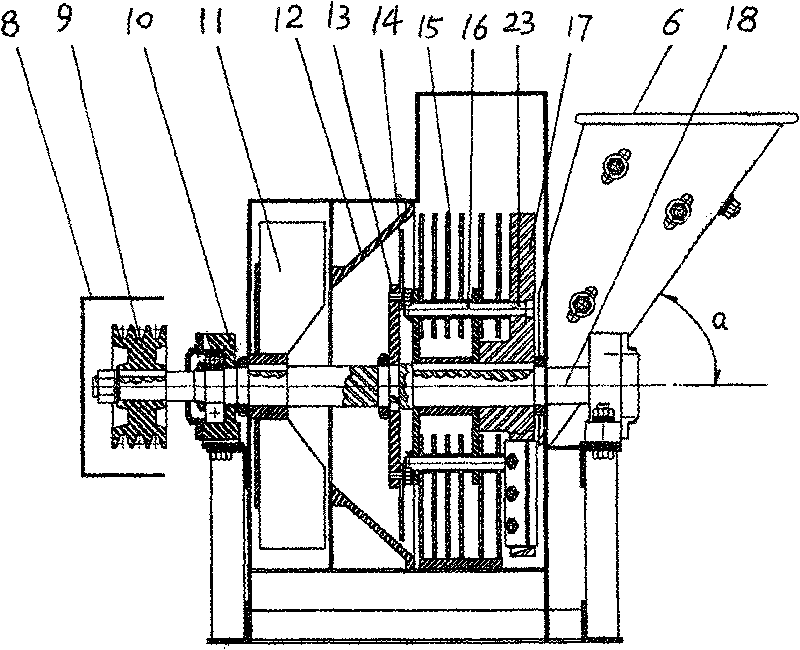

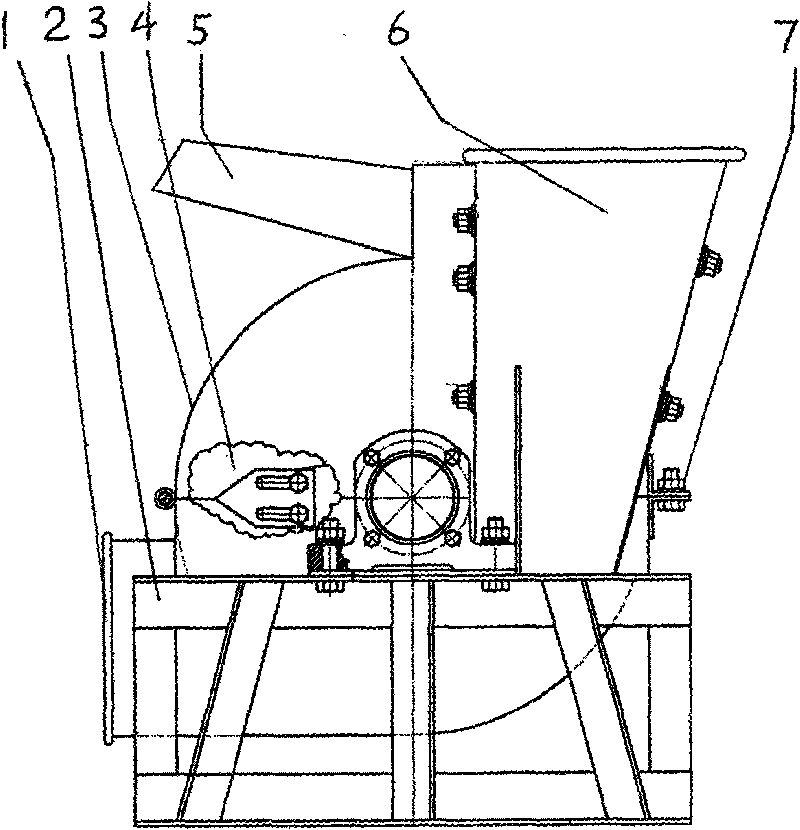

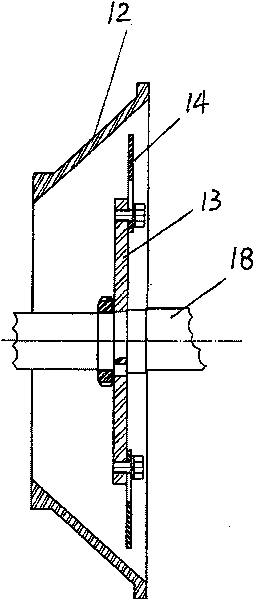

[0011] With reference to the accompanying drawings, it can be known that the concrete parts of the whole machine structure of the present invention mainly include: 1~discharging port, 2~frame, 3~casing (constitutes hammer crushing chamber by upper and lower casing), 4~granularity Regulator, 5~tangential feeding port, 6~lateral feeding port, 7~bolts for fixing upper and lower casings, 8~belt pulley safety cover, 9~V-belt pulley, 10~bearing seat, 11~suction fan , 12 ~ funnel-shaped (trumpet-shaped) collection cover for thickness regulator, 13 ~ regulator mounting frame, 14 ~ thickness adjustment sheet, 15 ~ hammer group, 16 ~ hammer shaft for installing hammer group, 17~revolving cutter head, 18~driving shaft, 19~adjusting sheet mounting hole, 20~cutting blade, 21~pressing knife plate, 22~knife locking bolt, 23~hammer Shaw positioning hole.

[0012] The plant material cutting and pulverizing machine includes a frame 2, an upper and lower casing 3 constituting a hammer crushing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com