Anti-static film and preparation method thereof

An anti-static and film technology, applied in the field of anti-static film and its preparation, can solve the problem of inability to discharge static electricity, and achieve the effect of good discharge effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

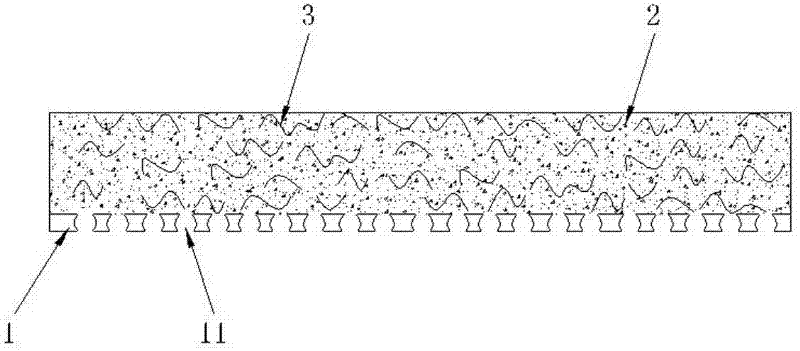

Image

Examples

preparation example Construction

[0021] The present invention also provides a kind of preparation method of antistatic film, and this method comprises the following steps:

[0022] A. Preparation of coating solution: Based on 100 parts by mass of pressure-sensitive resin, 5-50 parts by mass of organic solvent, and 1-30 parts by mass of nanowires, first disperse the nanowires in the organic solvent, and then add Stir evenly into the pressure-sensitive resin to obtain a coating liquid. In the present invention, the combined use of pressure-sensitive resin and nanowires cannot be generalized, and can be formulated according to the electrical properties of nanowires. If the mass fraction of nanowires exceeds 30, the light transmission performance of the coating will be reduced; If the mass fraction of the nanowires is less than 1, it is difficult to form a network structure, and the antistatic effect is not good. Preferably, relative to 100 parts by mass of the pressure-sensitive resin and 5-50 parts by mass of ...

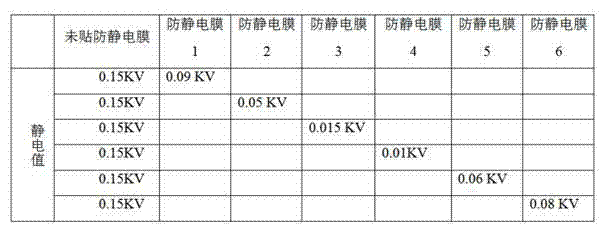

Embodiment 1

[0030] 1. Preparation of nanowires (taking zinc oxide nanowires as an example):

[0031] The purity of the reagents used below were all analytical grade, without further purification before use.

[0032]100 grams of zinc acetate, 3000 milliliters of absolute ethanol, 700 milliliters of polyethylene glycol, and 400 grams of sodium hydroxide were successively added to a 5000 milliliter polytetrafluoroethylene reaction kettle with a filling degree of 80%, then sealed in a stainless steel container, and After reacting at a constant temperature of 120 degrees for 12 hours, after naturally cooling to room temperature, the white precipitate was separated, washed several times with absolute ethanol and deionized water successively, and dried at a temperature of 100 degrees for 4 hours to obtain zinc oxide nanowires. The zinc oxide nanowires have a diameter of 20-26 nanometers and a length of 14 micrometers.

[0033] 2. Preparation of antistatic film:

[0034] Preparation materials: ...

Embodiment 2

[0037] 1. Preparation of nanowires (taking zinc oxide nanowires as an example):

[0038] The purity of the reagents used below were all analytical grade, without further purification before use.

[0039] 150 grams of zinc acetate, 3000 milliliters of absolute ethanol, 720 milliliters of polyethylene glycol, and 400 grams of sodium hydroxide were successively added to a 5000 milliliter polytetrafluoroethylene reaction kettle with a filling degree of 80%, then sealed in a stainless steel container, and After reacting at a constant temperature of 130 degrees for 12 hours, after naturally cooling to room temperature, the white precipitate was separated, washed several times with absolute ethanol and deionized water, and dried at a temperature of 100 degrees for 4 hours to obtain zinc oxide nanowires. The zinc oxide nanowires have a diameter of 22-30 nanometers and a length of 30 micrometers.

[0040] 2. Preparation of antistatic film:

[0041] Preparation materials: 100 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com