System and method for producing high-silicon sulphoaluminate cement by utilizing biomass ash

A technology of sulphoaluminate cement and biomass power plant ash, which is applied in the field of systems and methods for producing high-silicon sulphoaluminate cement by utilizing biomass ash slag, and can solve problems affecting the normal operation of shaft kilns, reducing cement strength, and cement strength. Instability and other problems, to achieve the effect of comprehensive and high value-added utilization, not easy to form loops, and prolong the life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

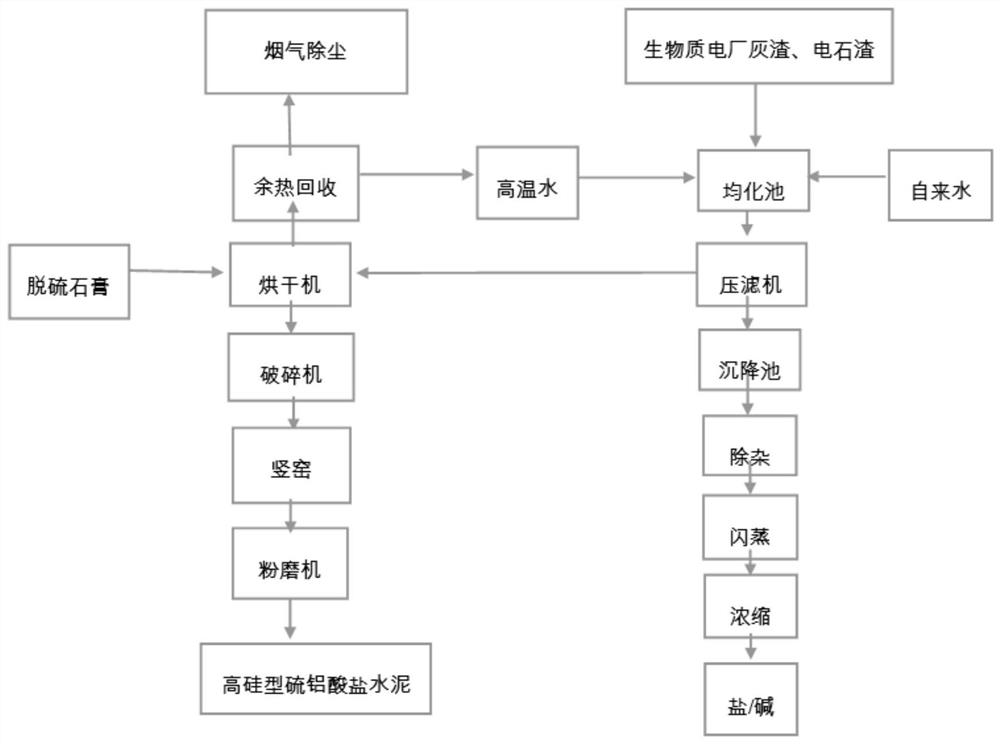

[0064] A system for producing high-silicon sulfoaluminate cement using industrial solid waste biomass power plant ash pretreatment, including ash homogenization tank, sedimentation tank, flash evaporator, concentrator, filter press, crusher, drying machine, shaft kiln, cement pulverizer, cement storage tank, waste heat recovery device, dust collector. Among them, the biomass power plant ash and calcium carbide slag are adjusted in the homogenization tank for dealkalization and desalination, and the slurry after dealkalization and desalination enters the filter press for filtration and drying in the dryer to obtain dry materials; desulfurization gypsum enters the drying process. Heating in a desiccator converts it into hemihydrate gypsum with a water content of less than 3%; the filtrate containing alkali and salt is evaporated, concentrated and crystallized to obtain alkali and salt.

[0065] The ash slag grinder, the homogenization tank and the filter press are connected in s...

Embodiment 2

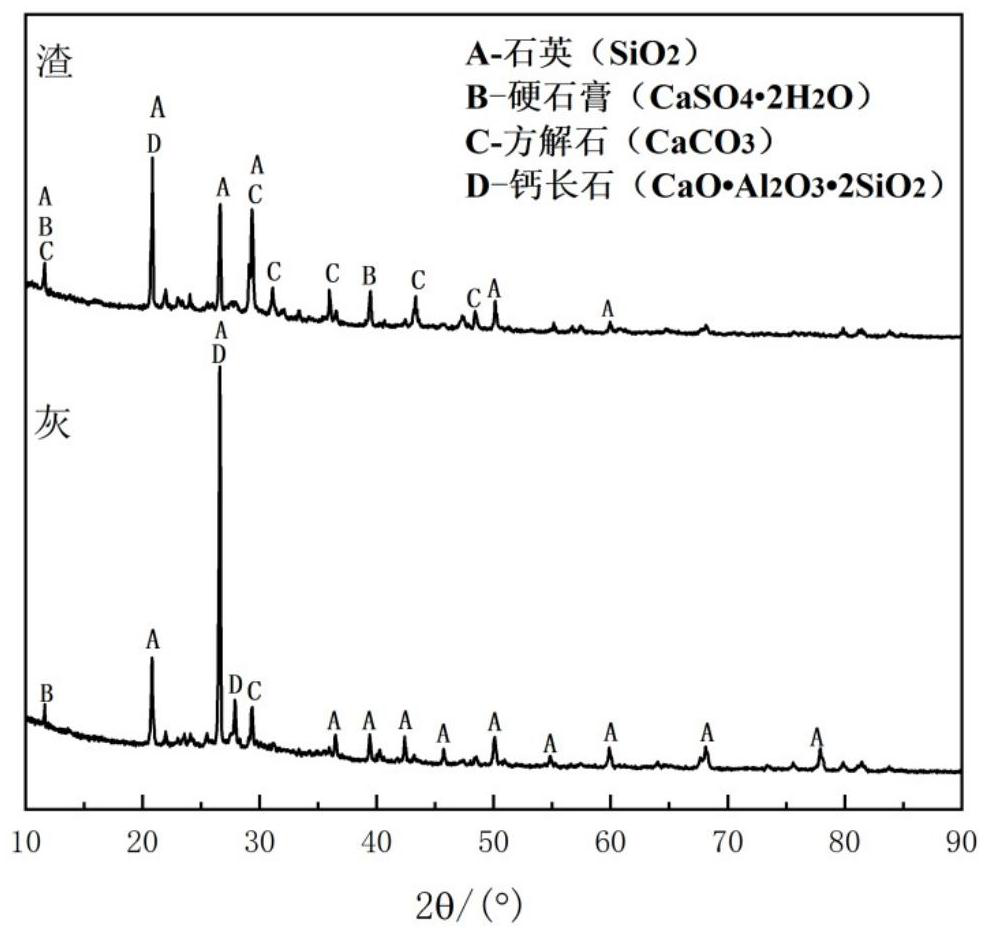

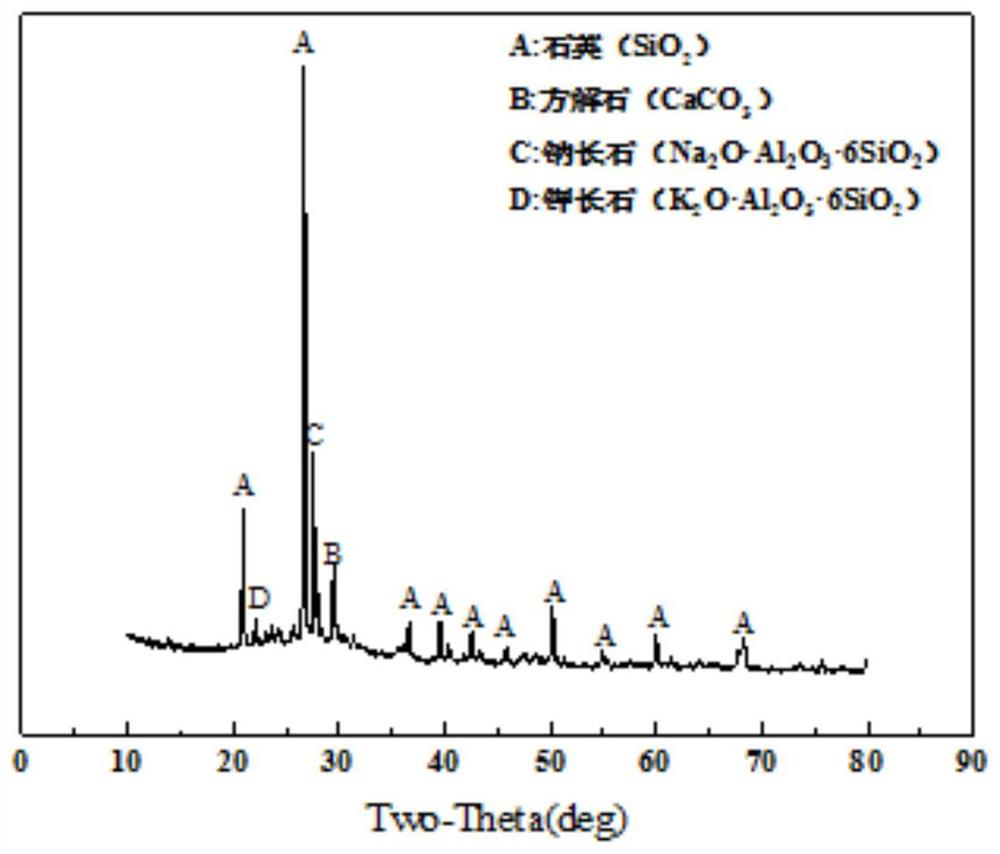

[0069] A method for producing high-silicon sulfoaluminate cement by utilizing industrial solid waste biomass power plant ash and slag pretreatment. The biomass power plant ash, biomass power plant slag and calcium carbide slag are mixed and homogenized, and the solid-liquid ratio is 1:3 , get the alkali-containing slurry, and use the waste heat equipment to recover the waste heat of the dryer flue gas to heat the alkali-containing slurry, so that the temperature of the alkali-containing slurry is maintained at 60-70 ℃, so that the alkali content in the biomass ash and slag is reduced to the original 10% or less, the moisture content of the batching slurry after pressure filtration is 35% (wt%), and after natural drying, the moisture content is reduced to 16% (wt%). The dried raw meal is sent into the dryer. In terms of the dried solid matter, biomass power plant ash accounts for 27 parts by weight, biomass power plant slag accounts for 30 parts, desulfurization gypsum accounts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com