A method for efficient extraction, separation and recovery of chromium and silicon in vanadium extraction tailings

A technology of vanadium tailings extraction, separation and recovery, which is applied in the direction of silicate, alkaline earth metal silicate, chromate/dichromate, etc., to achieve the effects of low production cost, low silicon content and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] In order to better illustrate the present invention and facilitate understanding of the technical solution of the present invention, the present invention will be further described in detail below. However, the following embodiments are only simple examples of the present invention, and do not represent or limit the protection scope of the present invention, and the protection scope of the present invention shall be determined by the claims. Embodiments of the present invention are as follows:

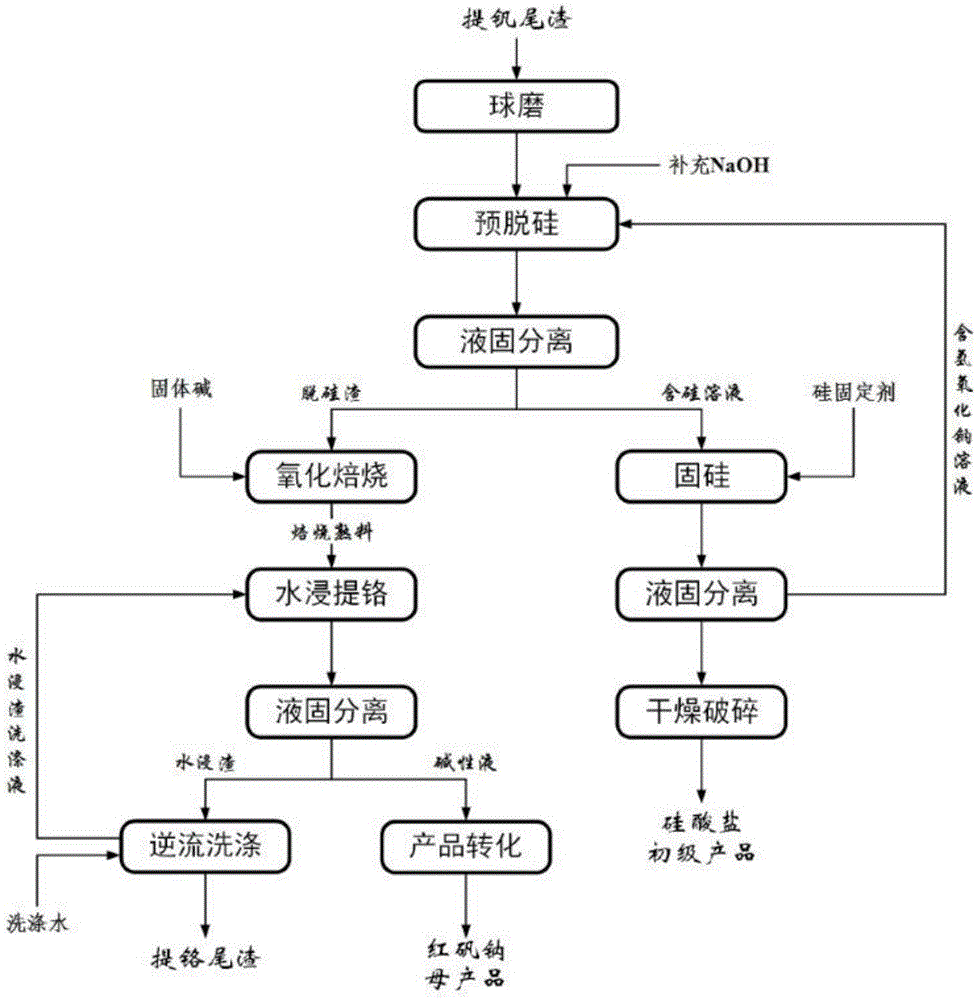

[0046] A process for extracting, separating and recovering chromium and silicon in vanadium extraction tailings, comprising the following steps:

[0047] (1) The vanadium extraction tailings after ball milling or crushing and 10-20wt% sodium hydroxide solution are mixed and heated according to the mass volume ratio of the vanadium extraction tailings and sodium hydroxide solution to 90~150℃, carry out pre-desiliconization reaction for 0.5~4h, and obtain desiliconization slag an...

Embodiment 1

[0054] In this embodiment, the vanadium extraction tailings are used, containing 5.34wt% Cr, 12.74wt% Si, and 18.49wt% TFe.

[0055] (1) 50g of vanadium extraction tailings are carried out by ball milling;

[0056] (2) Prepare 10wt% sodium hydroxide solution, mix the sodium hydroxide solution with vanadium extraction tailings in a reactor, the mass volume ratio of slag to alkali is 1:20, pre-desilicate at 150°C for 4 hours. After liquid-solid separation, desiliconization slag and silicon-containing solution are obtained;

[0057] (3) Take quicklime according to the molar ratio of Ca and Si in the silicon-containing solution of 0.8:1, and add water and stir according to the mass ratio of quicklime (calculated as CaO) and water as 1:4 to obtain milk of lime, and add the milk of lime to the solution containing In the silicon solution, solidify the silicon at 150°C for 4 hours, and then separate the liquid and solid to obtain the aqueous calcium silicate and sodium hydroxide solu...

Embodiment 2

[0061] In this embodiment, the vanadium extraction tailings are used, containing Cr1.35wt%, Si7.03wt%, TFe26.30wt%.

[0062] (1) 50g of vanadium extraction tailings are carried out by ball milling;

[0063] (2) Prepare 12wt% sodium hydroxide solution, mix the sodium hydroxide solution with vanadium extraction tailings in a reactor, the mass volume ratio of slag to alkali is 1:18, and pre-desilicate at 140°C for 3 hours. After liquid-solid separation, desiliconization slag and silicon-containing solution are obtained;

[0064] (3) Take quicklime according to the molar ratio of Ca and Si in the silicon-containing solution of 0.9:1, and add water and stir according to the mass ratio of quicklime (calculated as CaO) and water as 1:4.5 to prepare milk of lime, and add the milk of lime to the solution containing In the silicon solution, solidify silicon at 130°C for 3 hours, and then separate the liquid and solid to obtain hydrous calcium silicate and sodium hydroxide solution. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com