Plastic cleaning equipment

A plastic cleaning and equipment technology, applied in plastic recycling, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as large buoyancy, reduced performance, time-consuming and labor-intensive cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

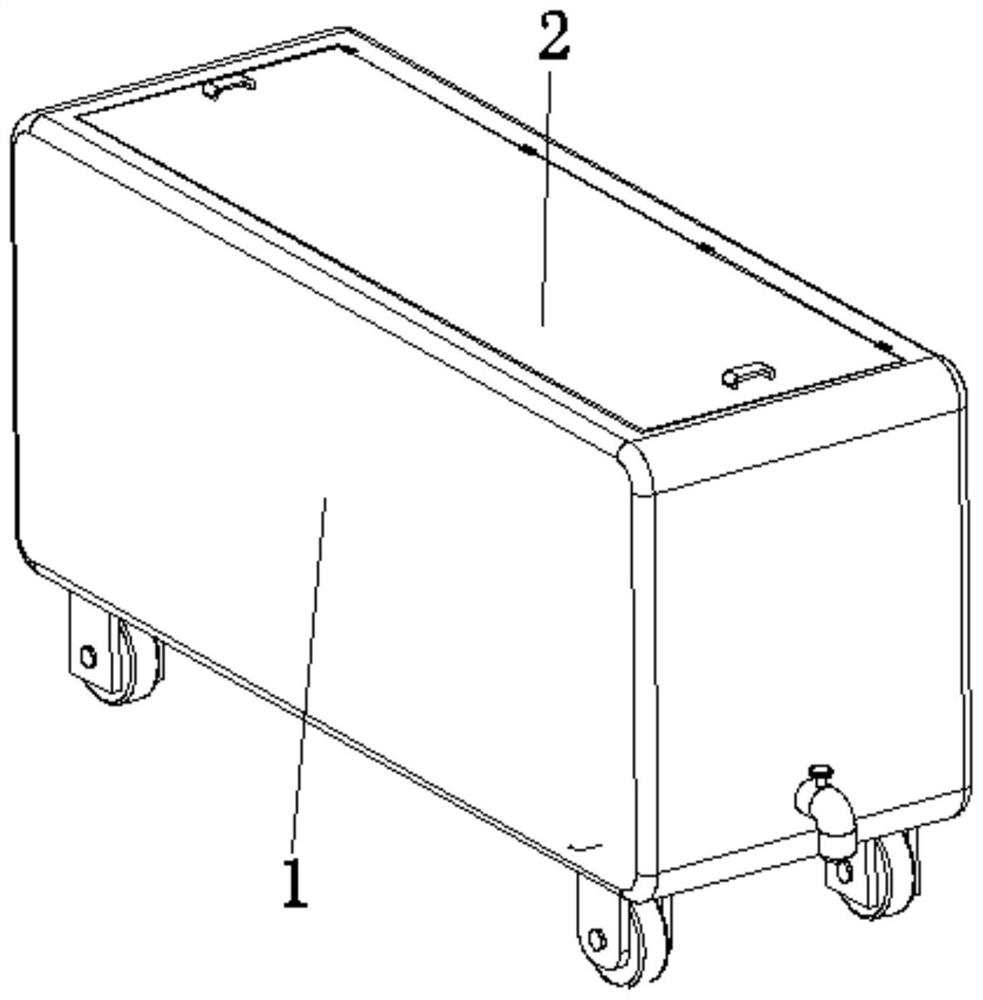

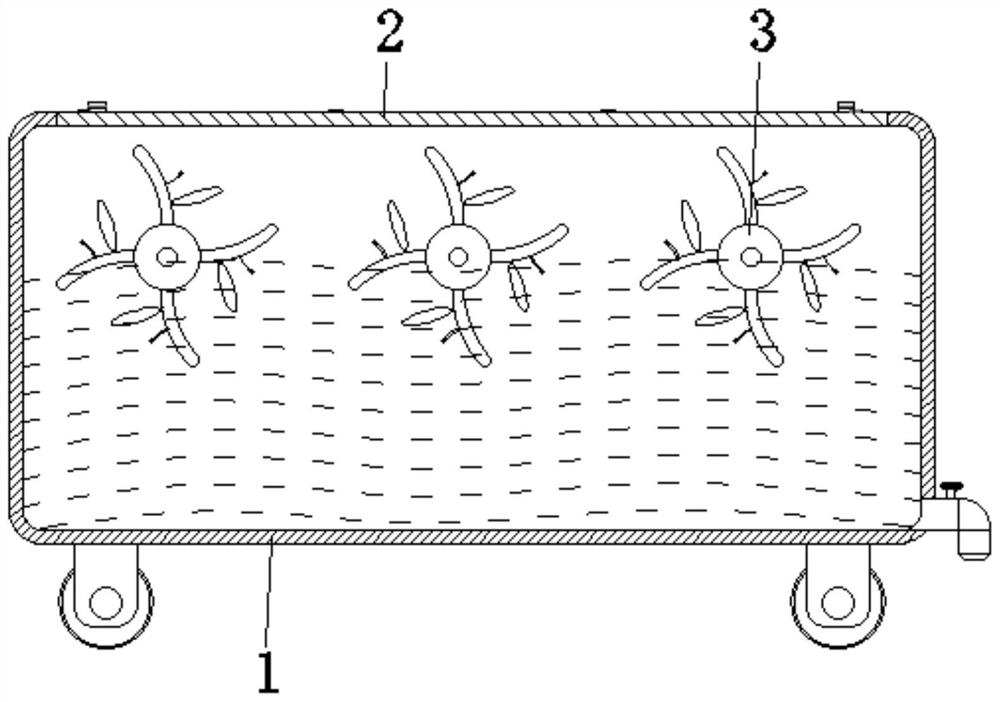

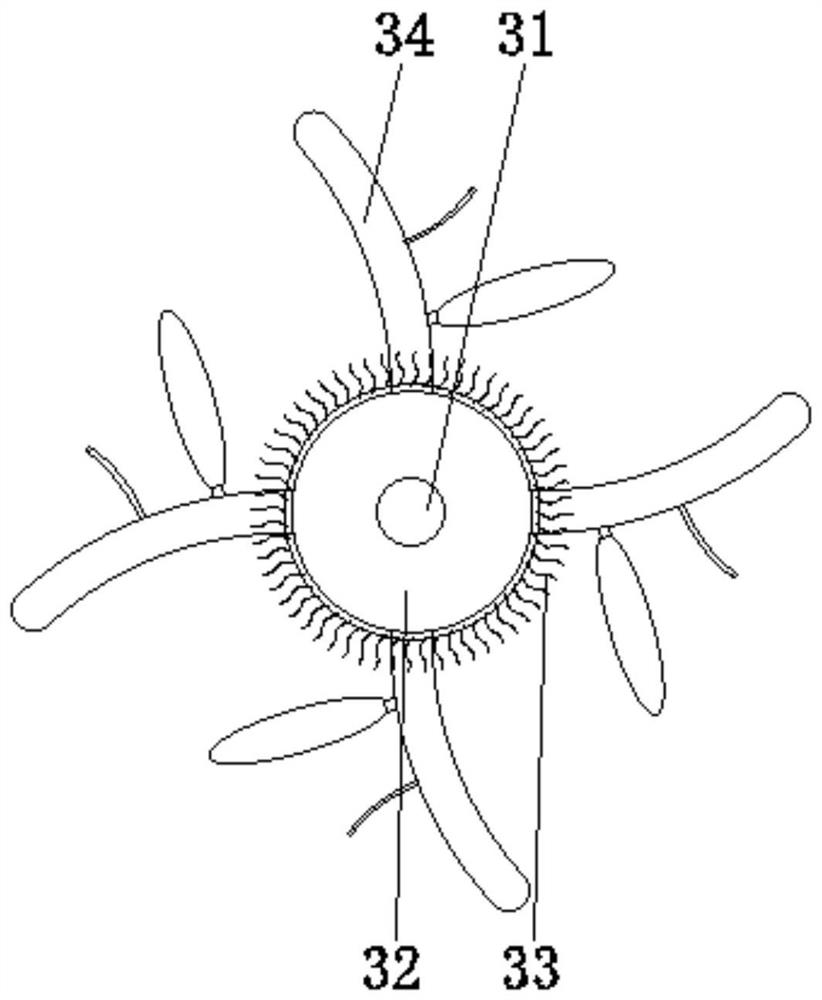

[0034] see Figure 1-8 , the present invention provides a technical solution: a plastic cleaning equipment, including a cleaning box 1, a top cover 2, and a cleaning device 3, the top cover 2 is rotatably connected to the top center of the cleaning box 1, and the cleaning device 3 is rotatably connected to the cleaning box 1 Between the corresponding two sides of the inner wall and close to the top cover 2, the cleaning device 3 is evenly distributed inside the cleaning box 1. The cleaning device 3 is provided with a driving shaft 31, a roller 32, a cleaning brush 33, a scrubbing device 34, and a roller 32 is fixed on the surface central position of driving shaft 31 and is positioned at the inside of cleaning box 1, and cleaning brush 33 is fixed on the surface of cylinder 32, and cleaning brush 33 is evenly distributed on the surface of cylinder 32, and brushing device 34 is fixed on the surface of cylinder 32, can Cleaning sheet plastics floating on the water surface reduces...

Embodiment example 2

[0039] The lever device 346 is provided with a lever body 3461, a channel 3462, a connecting hole 3463, an elastic film 3464, and a brush 3465. The channel 3462 is set at the inner center of the lever body 3461, and one end of the channel 3462 communicates with the elastic airbag 345, and connects The hole 3463 is set inside the lever body 3461 and communicates with the channel 3462. The elastic film 3464 is fixed on the surface of the lever body 3461 and is located in the connection. When the lever body 3461 is moved, the accumulated plastic is in a vertical state. Under the effect of its own buoyancy, it rises rapidly so as to scrub. When the elastic airbag 345 discharges gas into the passage 3462 and the connecting hole 3463, the elastic membrane 3464 is bulged under the influence of pressure, and then the brush 3465 is attached to the rising plastic. Surface, so as to use the rise of the plastic itself for automatic cleaning.

[0040] During use, the sheet-like floating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com