Energy-saving type active-lime terminal roasting kiln

A technology of active lime and roasting kilns, which is applied in the field of roasting kilns for roasting limestone or dolomite, which can solve problems such as uneven air distribution and temperature distribution, poor uniformity of material distribution, and influence on normal production of the kiln, and achieve air distribution and Uniform temperature distribution, ensuring product quality, and not easy to form rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

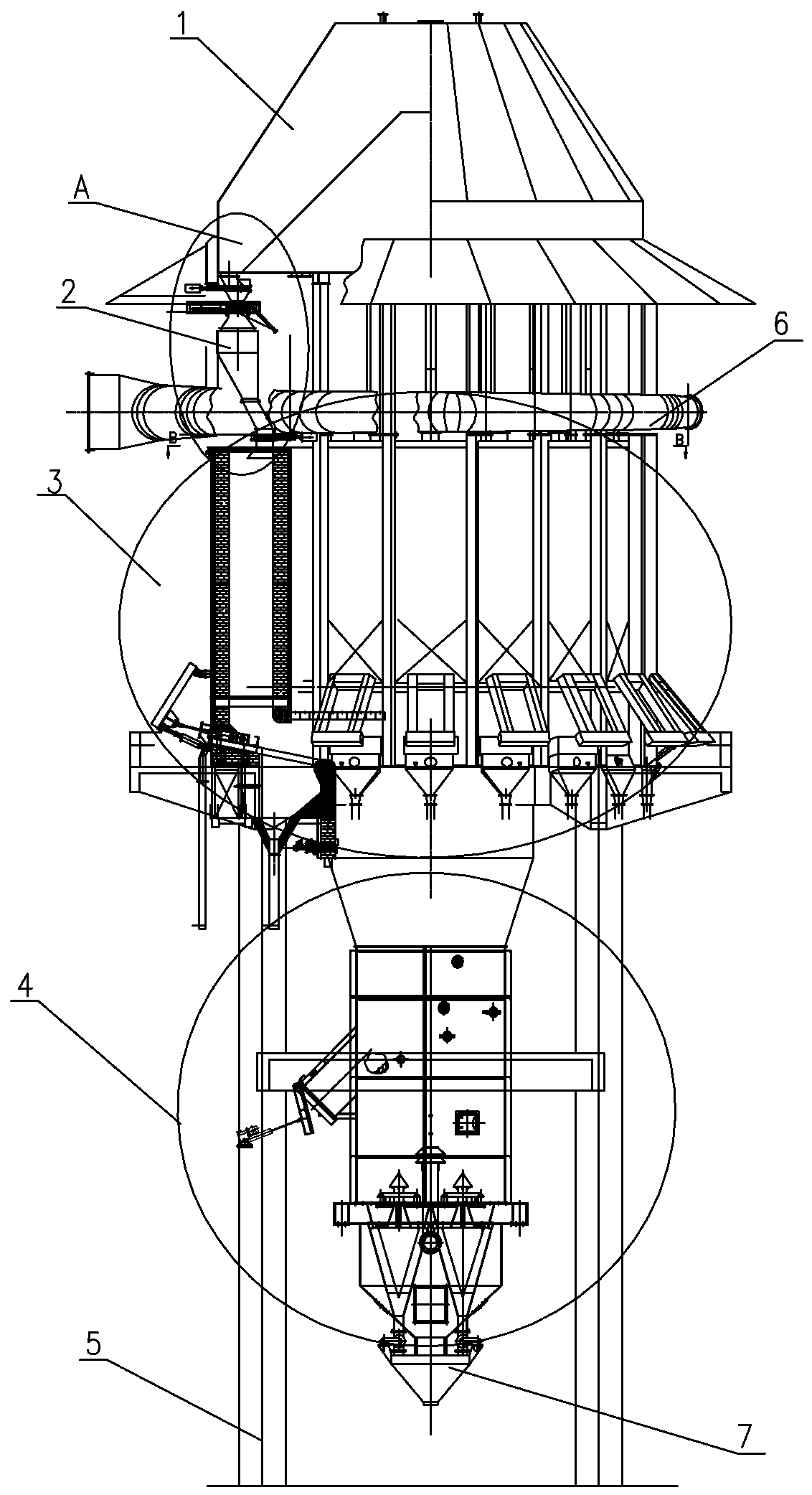

Embodiment 1

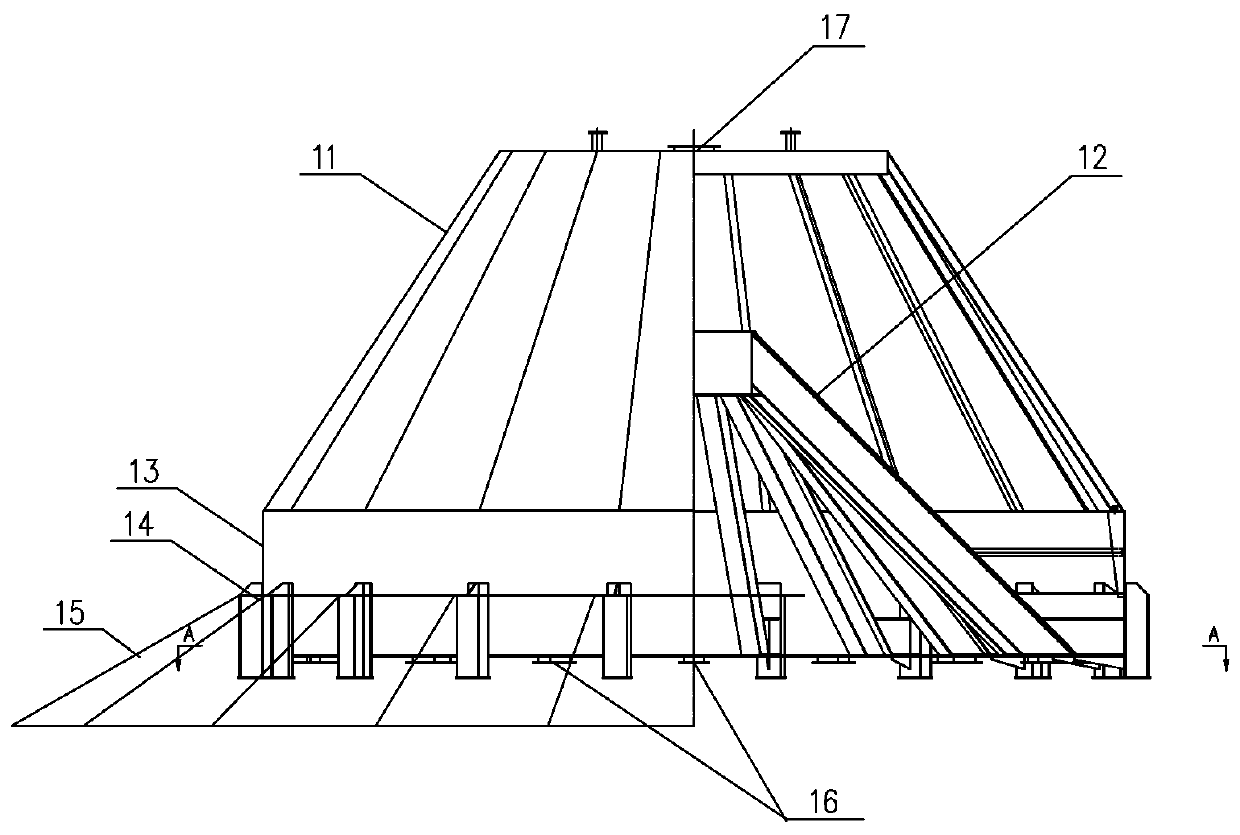

[0044] The roasting kiln body of the present invention is composed of a plurality of even-numbered fan-shaped kiln chambers, and a combustion chamber is provided between the fan-shaped kiln chambers and the cooling device. The lower part of the roasting kiln body adopts a positive pressure system, and the top adopts a negative pressure pressure system. The top negative pressure operation, It can not only reduce the temperature of the top cover, improve the working environment, protect the feeding equipment, but also improve the penetration ability of smoke, which is conducive to safe production.

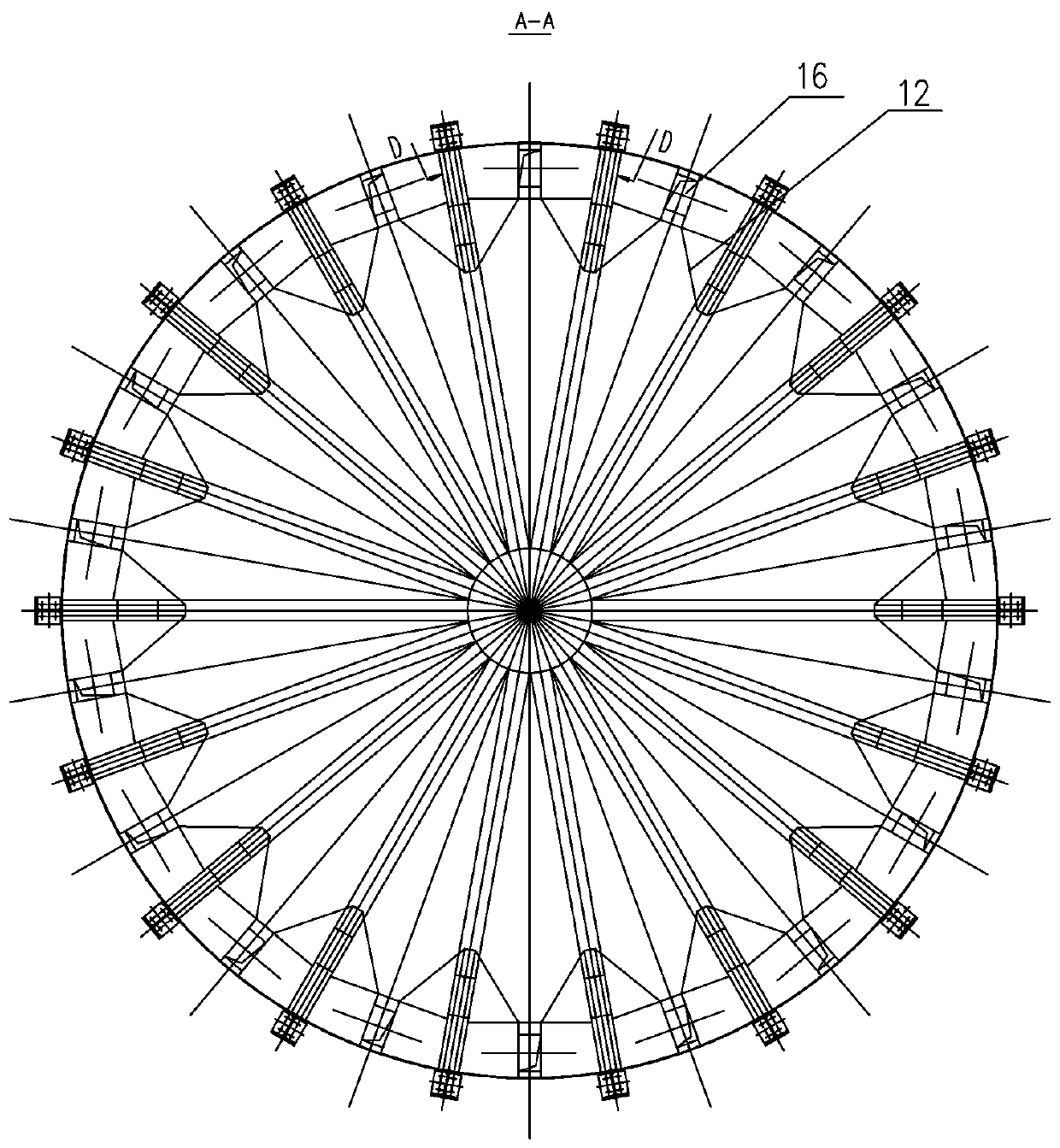

[0045] In the embodiment of the present invention, the cross section of the kiln body of the roasting kiln is formed into an annular belt, and the annular belt is divided into 18 fan-shaped kiln chambers 31 by refractory materials to form a porous kiln. The top 4.35 meters of the fan-shaped kiln cavity 31 is the preheating zone Y, the middle part 4.9 meters is the roasting zone P, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com