Method for evaluating corrosion inhibition performance of vapor-phase corrosion inhibitor

A gas-phase corrosion inhibitor and evaluation method technology, which can be used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., and can solve problems such as on-site corrosion and perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

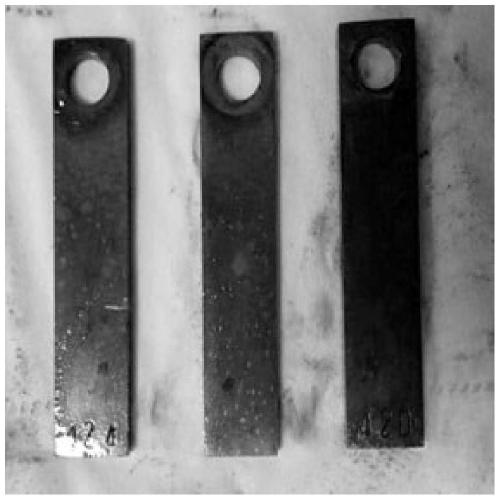

Embodiment 1

[0046] Take the on-site water as the corrosion medium, and the filling concentration of the gas-phase corrosion inhibitor in the on-site water is 0ppm. Take six metal test pieces with the same material as the sea pipe, wash them with alcohol and acetone to remove oil, dry them and weigh them to get the test piece samples. Fasten the test piece samples on the fixture in two layers, place the fixture with the test piece sample in the dynamic evaluation reaction kettle, introduce the on-site water without adding gas phase corrosion inhibitor into the dynamic reaction kettle, and make the three test pieces The sample is suspended above the liquid level of the on-site water, and the other three test piece samples are immersed in the on-site water, the speed of the fixture is 0.5m / s, the dynamic reactor is purged with nitrogen to discharge the air, and the dynamic evaluation reactor is fed with CO 2 and H 2 The nitrogen pressure of S was increased to 8MPa, and the temperature was ra...

Embodiment 2

[0052] The on-site water is used as the corrosion medium, and the gas-phase corrosion inhibitor in the on-site water is CTQH-1001 gas-phase corrosion inhibitor produced by CNOOC Changzhou Coating Chemical Research Institute Co., Ltd., whose main component is morpholine quaternary ammonium salt. The filling concentration is 200ppm, and six pieces are taken The metal test piece of the same material as the sea pipe is washed with alcohol and acetone to remove oil, dried and weighed to obtain the test piece sample, and the test piece sample is fastened on the fixture in two layers, and the fixture containing the test piece sample is placed on the In the dynamic evaluation reactor, the on-site water added with the gas phase corrosion inhibitor is introduced into the dynamic reactor, so that three test piece samples are suspended above the liquid level of the on-site water, and the other three test piece samples are immersed in the on-site water. The rotation speed is 0.5m / s, the dyn...

Embodiment 3

[0058] Take simulated water as the corrosion medium, and the filling concentration of the vapor phase corrosion inhibitor in the simulated water is 0ppm. Take six metal test pieces with the same material as the sea pipe, wash them with alcohol and acetone to remove oil, dry them and weigh them to get the test piece samples. Fasten the test piece sample on the fixture in two layers, place the fixture with the test piece sample in the dynamic evaluation reaction kettle, introduce the simulated water without adding gas phase corrosion inhibitor into the dynamic reaction kettle, and make the three test pieces The sample is suspended above the liquid surface of the simulated water, and the other three test piece samples are immersed in the simulated water, the speed of the fixture is 0.5m / s, the dynamic reactor is purged with nitrogen to discharge the air, and the dynamic evaluation reactor is fed with CO 2 and H 2 The nitrogen pressure of S was increased to 8MPa, and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com