a fe 2+ Metal-organic framework corrosion inhibitor-hydrogel composite with responsive properties and its preparation method and application

A metal-organic framework and corrosion inhibitor technology, used in coatings, anti-corrosion coatings, etc., can solve various problems such as stress damage, dispersion limited corrosion inhibition performance, poor compatibility of corrosion inhibitors, etc., to improve integrity, The effect of slowing growth rate, high-volume encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

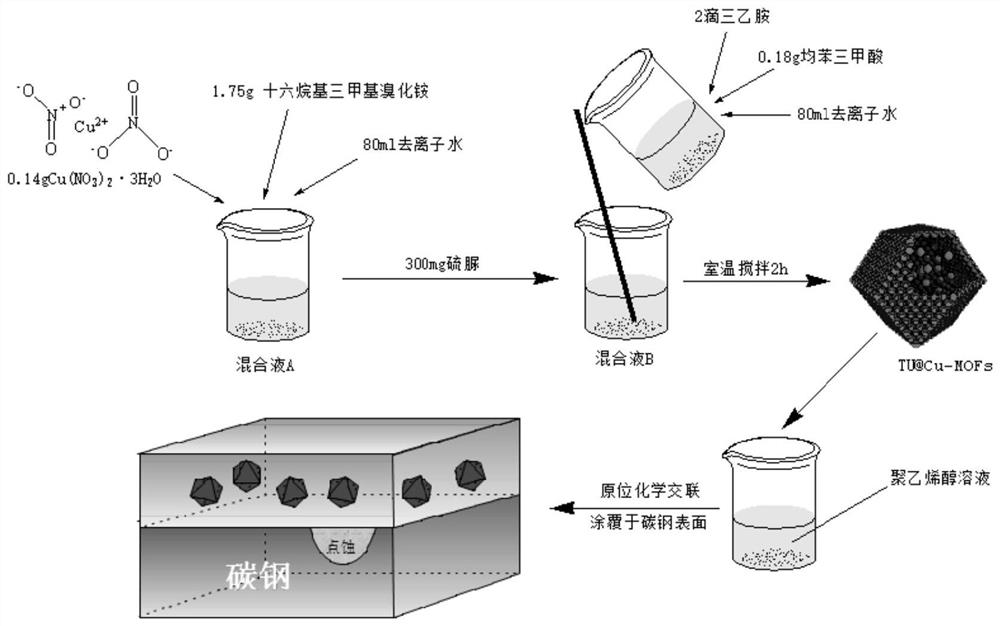

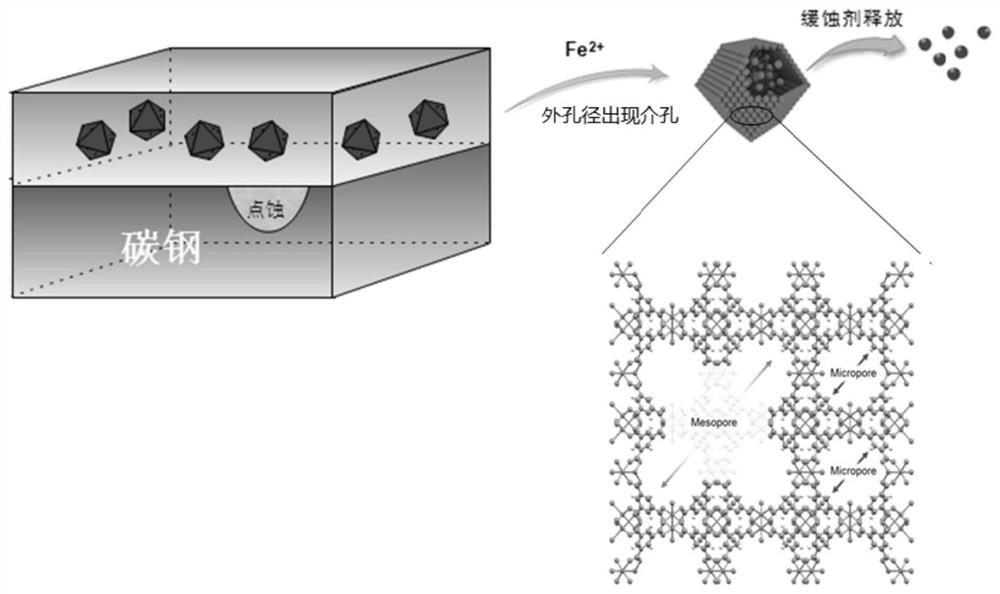

[0041] The preparation of PVA hydrogel doped copper-based carboxylate metal-organic frameworks to encapsulate thiourea complexes containing tertiary amine groups, the preparation process is as follows figure 1 Shown:

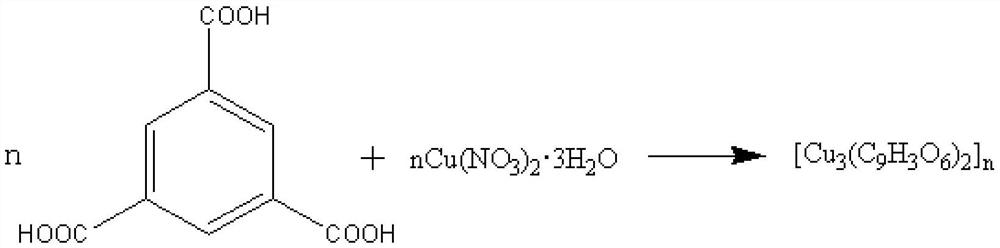

[0042] The first step: Synthesis of copper-based carboxylate metal organic framework to encapsulate the precursor of thiourea corrosion inhibitor, wherein the synthesis reaction formula of copper-based carboxylate metal organic framework is shown in the following reaction equation:

[0043]

[0044] First add copper nitrate trihydrate (60mg, 0.25mmol) and hexadecyltrimethylammonium bromide (1.82g, 5.0mmol) to 80ml deionized water in a molar ratio of 0.05:1, shake and mix well, then add 150mg (2.0mmol) thiourea to prepare mixed solution A; then add 0.185g (0.9mmol) trimesic acid to another beaker and dissolve it with 80ml deionized water, then drop 2 drops of triethylamine solution to prepare mixed solution Solution B: after mixing the two solutions, a copper...

Embodiment 2

[0048] Preparation of PVA Hydrogel Doped Copper-Based Carboxylate Metal-Organic Framework Encapsulated Thiourea Complex Containing Tertiary Amino Groups

[0049] The first step: Synthesis of copper-based carboxylate metal-organic frameworks to encapsulate thiourea corrosion inhibitor precursors

[0050] First, copper nitrate trihydrate (121mg, 0.5mmol) and cetyltrimethylammonium bromide (1.82g, 5.0mmol) were added to 80ml deionized water at a molar ratio of 0.1:1, shaken and mixed, and then 300mg (3.9mmol) thiourea to prepare mixed solution A; then add 0.185g (0.9mol) trimesic acid in another beaker and dissolve it with 80ml deionized water, then drop 2 drops of triethylamine solution to prepare mixed solution Solution B: after mixing the two solutions, a copper-based carboxylate metal-organic framework-encapsulated thiourea corrosion inhibitor precursor is obtained.

[0051] Step 2: Encapsulation of thiourea corrosion inhibitor complexes by doping copper-based carboxylate me...

Embodiment 3

[0054] Preparation of PVA Hydrogel Doped Copper-Based Carboxylate Metal-Organic Framework Encapsulated Thiourea Complex Containing Tertiary Amino Groups

[0055] The first step: Synthesis of copper-based carboxylate metal-organic frameworks to encapsulate thiourea corrosion inhibitor precursors

[0056] Copper nitrate trihydrate (241mg, 1.0mmol) and cetyltrimethylammonium bromide (1.82g, 5mmol) were first added to 80ml deionized water in a molar ratio of 0.2:1 and shaken to mix well, and then 400mg ( 5.3mmol) thiourea to make mixed solution A; then add 0.185g (0.9mol) trimesic acid in another beaker and dissolve it with 80ml deionized water, then drip 2 drops of triethylamine solution to make mixed solution B; The copper-based carboxylate metal-organic framework-encapsulated thiourea corrosion inhibitor precursor is obtained after the two solutions are mixed.

[0057] Step 2: Encapsulation of thiourea corrosion inhibitor complexes by doping copper-based carboxylate metal-orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com