Preparation method of long-oil alkyd resin anticorrosive enamel paint with high corrosion potential

A technology of long oil degree alkyd and corrosion potential, applied in the field of enamel paint, can solve the problems of not meeting anti-corrosion requirements and complex preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Material handling

[0019] The material was polished with 1.0 μm and 0.3 μm alumina powder on a polishing cloth in turn, then placed in 5% hydrochloric acid for 5 min, then placed in deionized water for ultrasonic cleaning for 3 times, each time for 5 min, and finally placed in an Sonicated in water and ethanol for 6 min and then dried for later use.

[0020] 2. Preparation of alkyd resin anticorrosive enamel

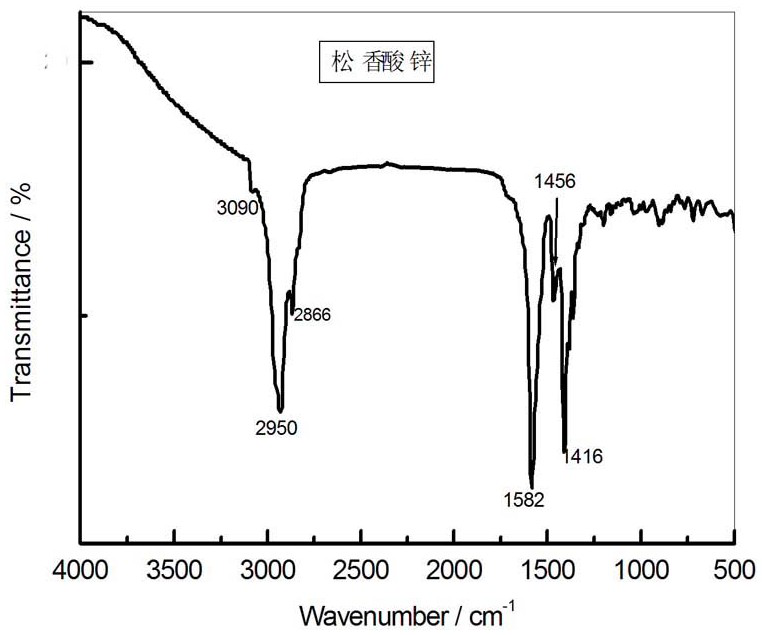

[0021] Add 1 mole of abietic acid and 2 moles of zinc acetate into the pulverizer, grind and disperse for 3 minutes at 3000 rpm, then transfer to a crucible, react in a reaction box at 180 degrees Celsius for 40 minutes, and then Transfer to the pulverizer while hot, pulverize for 3 minutes after cooling, then wash the product with a volume ratio of 30% ethanol aqueous solution, and dry it for 1 hour at a temperature of 80 degrees Celsius to obtain zinc abietate;

[0022] Add 30 parts by weight of dry long-oil alkyd resin, 2 parts by weight of zinc abietat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com