Metal organic formwork corrosion inhibitor-hydrogel compound with Fe2+ response characteristic, and preparation method and application thereof

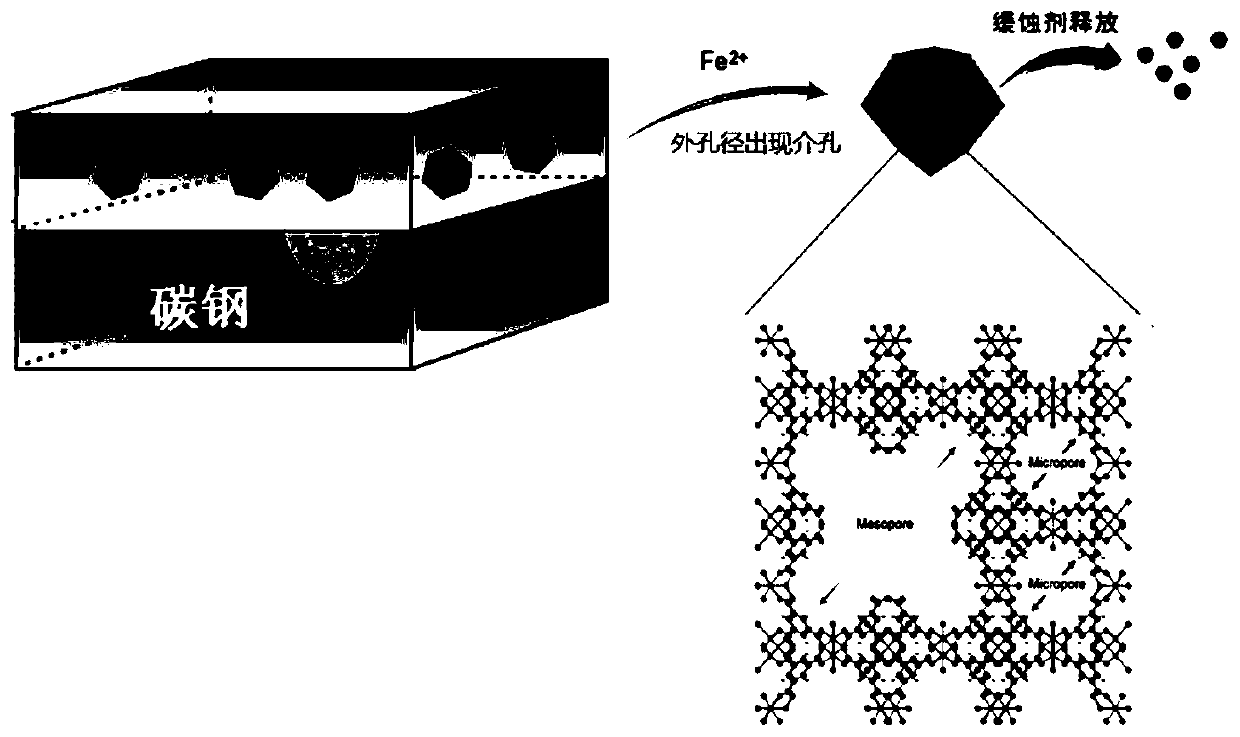

A metal-organic framework and responsive technology, applied in coatings, anti-corrosion coatings, etc., can solve various problems such as stress damage, dispersion-limited corrosion inhibition performance, poor compatibility of corrosion inhibitors, etc., to improve integrity, achieve Sensitization of anticorrosion properties, effect of retarding growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

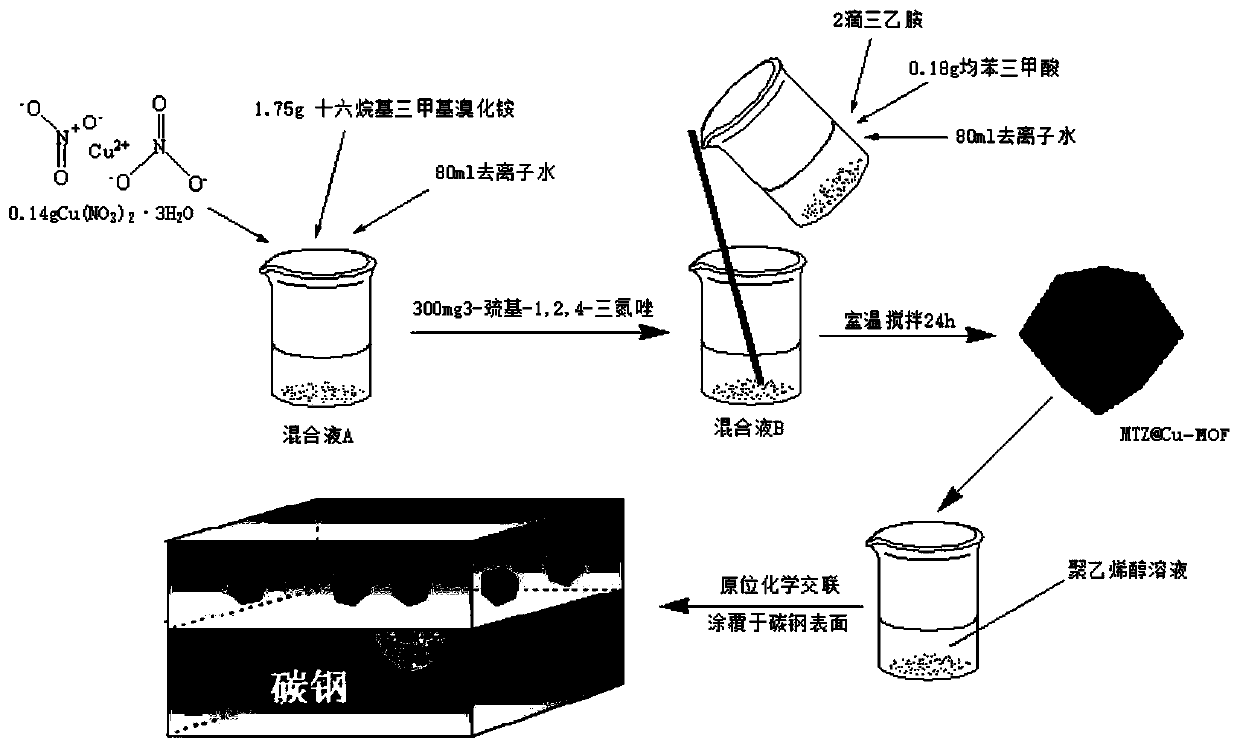

[0041] Preparation of PVA hydrogel doped copper-based carboxylic acid metal-organic framework to encapsulate 3-mercapto-1,2,4-triazole complexes containing mercapto groups, the preparation process is as follows figure 1 Shown:

[0042] The first step: Synthesis of copper-based carboxylic acid metal organic framework to encapsulate the precursor of 3-mercapto-1,2,4-triazole corrosion inhibitor, wherein the synthesis reaction formula of copper-based carboxylic acid metal organic framework is shown in the following reaction equation:

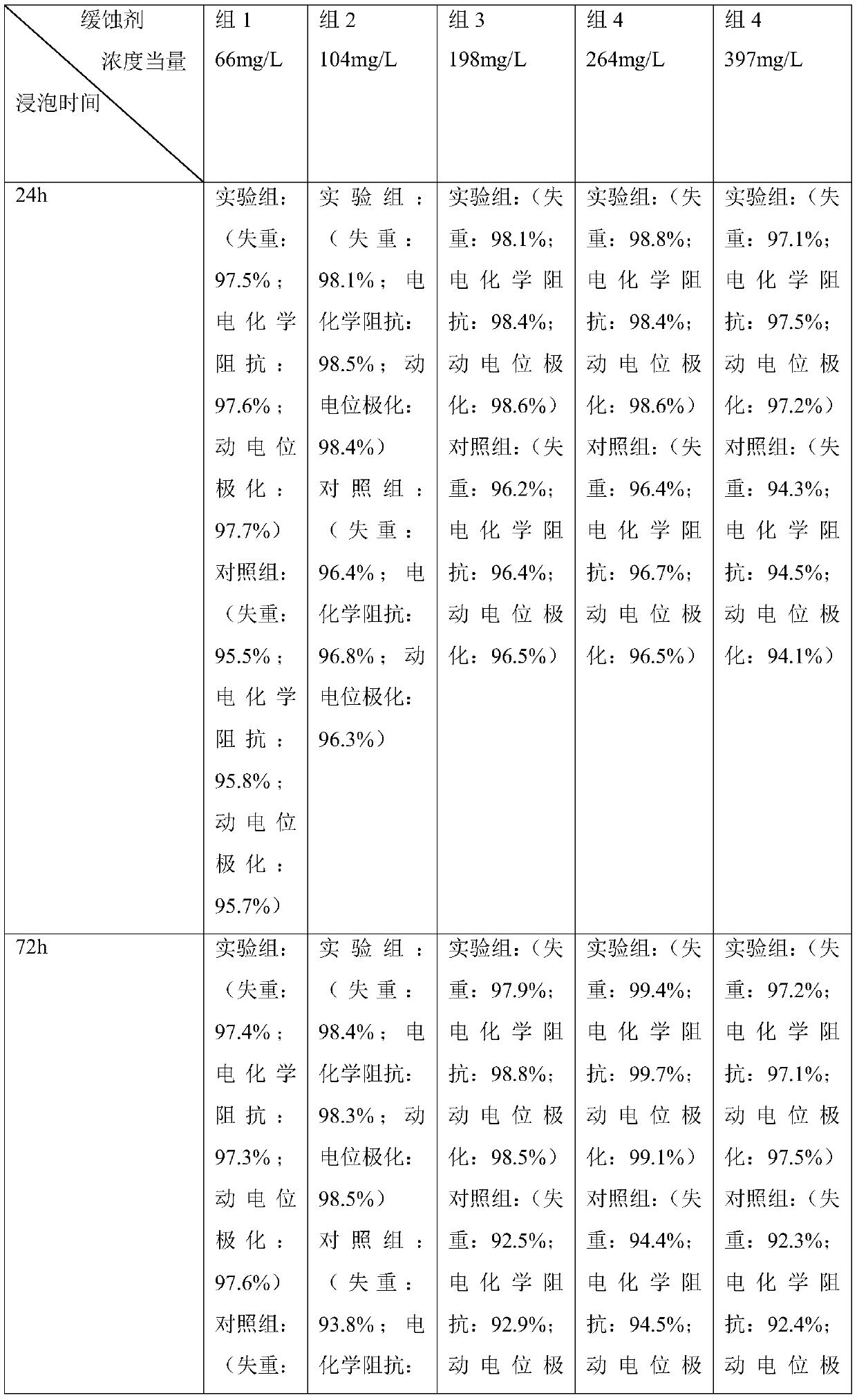

[0043] First add copper nitrate trihydrate (60mg, 0.25mmol) and cetyltrimethylammonium bromide (1.82g, 5.0mmol) to 80ml deionized water in a molar ratio of 0.05:1, shake and mix well, then add 150mg (2.0mmol) 3-mercapto-1,2,4-triazole to prepare mixed solution A; then add 0.185g (0.9mmol) trimesic acid to another beaker and dissolve it with 80ml deionized water, then drop Add 2 drops of triethylamine solution to prepare mixed solution B; after mix...

Embodiment 2

[0047] Preparation of 3-mercapto-1,2,4-triazole complexes containing mercapto groups encapsulated in PVA hydrogel doped copper-based carboxylic acid metal-organic frameworks

[0048] The first step: Synthesis of copper-based carboxylate metal-organic framework to encapsulate 3-mercapto-1,2,4-triazole corrosion inhibitor precursor

[0049] First, copper nitrate trihydrate (121mg, 0.5mmol) and cetyltrimethylammonium bromide (1.82g, 5.0mmol) were added to 80ml of deionized water in a molar ratio of 0.1:1, shaken and mixed, and then 300mg (3.9mmol) 3-mercapto-1,2,4-triazole to prepare mixed solution A; then add 0.185g (0.9mol) trimesic acid to another beaker and dissolve it with 80ml deionized water, then drop Add 2 drops of triethylamine solution to prepare mixed solution B; after mixing the two solutions, a copper-based carboxylate metal organic framework-encapsulated 3-mercapto-1,2,4-triazole corrosion inhibitor precursor is obtained.

[0050] Step 2: Encapsulation of 3-mercap...

Embodiment 3

[0053] Preparation of 3-mercapto-1,2,4-triazole complexes containing mercapto groups encapsulated in PVA hydrogel doped copper-based carboxylic acid metal-organic frameworks

[0054] The first step: Synthesis of copper-based carboxylate metal-organic framework to encapsulate 3-mercapto-1,2,4-triazole corrosion inhibitor precursor

[0055] First, copper nitrate trihydrate (241mg, 1.0mmol) and cetyltrimethylammonium bromide (1.82g, 5mmol) were added to 80ml of deionized water in a molar ratio of 0.2:1, shaken and mixed, and then 400mg ( 5.3mmol) of 3-mercapto-1,2,4-triazole to prepare mixed solution A; then add 0.185g (0.9mol) of trimesic acid to another beaker and dissolve it with 80ml of deionized water, then drop into 2 drops of triethylamine solution to prepare mixed solution B; after mixing the two solutions, a copper-based carboxylate metal organic framework encapsulated 3-mercapto-1,2,4-triazole corrosion inhibitor precursor was obtained.

[0056] Step 2: Encapsulation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com