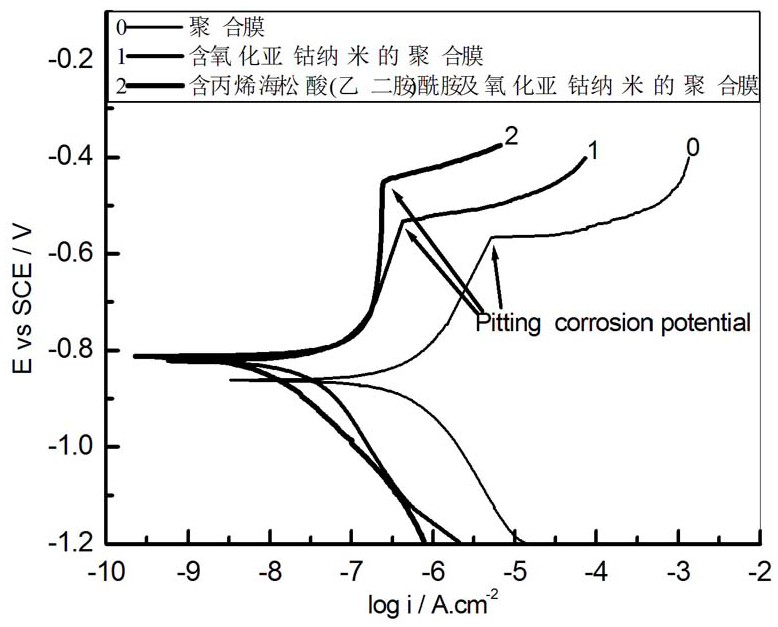

Preparation method of rosin-based thermal polymerization anti-corrosion film doped with cobaltous oxide nanoparticles with high pitting potential

A nano-cobaltous oxide thermal polymerization technology, applied in the field of anti-corrosion coatings, can solve the problems of global ecological environment impact, pollution of oceans, rivers and soil environment, poor anti-corrosion performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

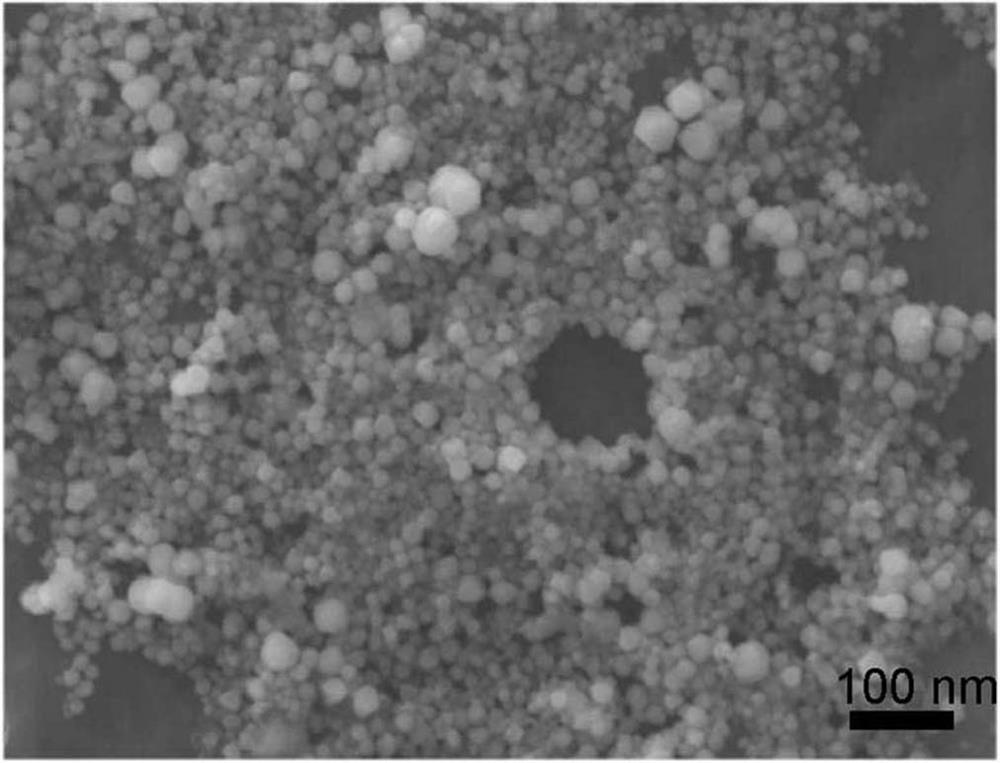

Image

Examples

Embodiment 1

[0015] 1. Treatment of 6063 aluminum alloy sheet

[0016] The 6063 aluminum alloy sheet was polished with 1.0 μm and 0.3 μm alumina powder on a polishing cloth in turn, then placed in 5% hydrochloric acid for 5 minutes, then placed in deionized water for 5 minutes, and finally placed in anhydrous Sonicated in ethanol for 6 min and dried for later use.

[0017] 2. Preparation of polymeric anticorrosion film

[0018] Add 0.01 g of cobalt (II) chloride, 1 g of glycerin, and 100 g of distilled water into the beaker, stir for 10 minutes, and slowly drop in a concentration of 0.01 g / hydrogen after the cobalt (II) chloride is dissolved. 10 ml of sodium oxide was stirred vigorously for 30 minutes, then transferred to a 200 ml stainless steel autoclave lined with polytetrafluoroethylene, reacted for 1 hour at a temperature of 150 degrees Celsius, then centrifuged to collect the precipitate, and washed with deionized water and ethanol for three times, and dried at a temperature of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com