High-density frozen-penetration-resistant marine concrete and preparation method thereof

A marine concrete and dense technology, which is applied in the field of high-density anti-freeze and seepage marine concrete and its preparation, can solve the problems of material deterioration, poor service performance, and peeling of the protective layer, so as to improve the anti-freeze seepage effect and meet the durability Requirements, the effect of improving the compactness of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-density anti-freezing and seepage marine concrete is prepared by the following method:

[0021] (1) Preparation of modified metakaolin: Using the excellent ball effect of silica fume to make up for the disadvantage that calcined metakaolin will reduce the workability of cement-based materials, the mass ratio of silica fume and calcined metakaolin is controlled at 4:1, and the silicon The ash and the calcined metakaolin are mixed and then placed in a ball mill for blending and ball milling. The ball-to-material ratio of the ball-milling blend is 100:6-100:8, and the ball-milling speed is 60r / min-80r / min to prepare the modified metakaolin;

[0022] (2) Determine the components of the gelling system:

[0023] a. Determine the components of mineral admixtures, select modified metakaolin and S95 mineral powder as mineral admixtures, and use the minimum water demand method to determine the ratio of the two. The specific test process is as follows:

[0024] Using a pur...

Embodiment 2

[0033] A high-density anti-freezing and seepage marine concrete is prepared by the following method:

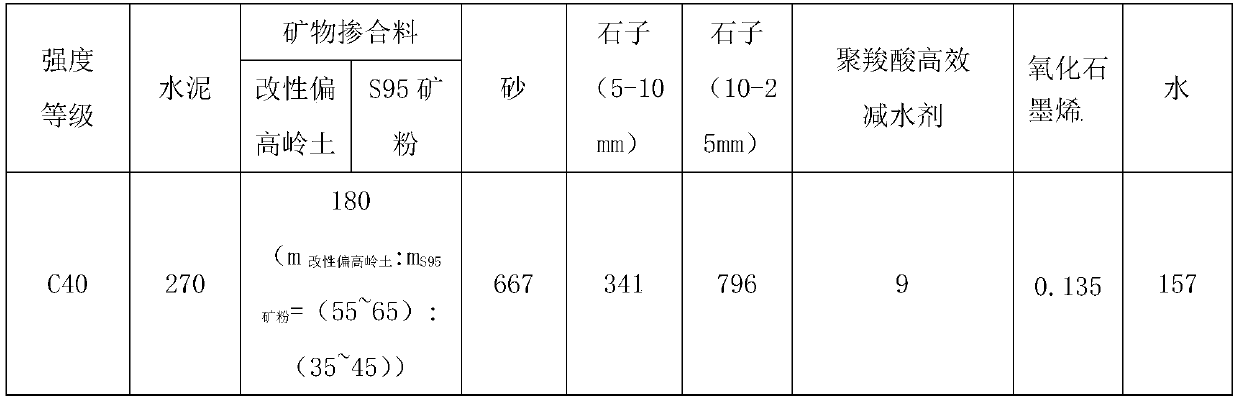

[0034] (1) The distribution ratio of each group is shown in Table 3 below;

[0035] Table 3 Optimized mix ratio (kg / m 3 )

[0036]

[0037] The raw materials for preparing concrete were sampled according to the proportions shown in Table 3, and were produced with reference to the standard of GB / T 50081 "Standard for Testing Method of Mechanical Properties of Ordinary Concrete". Add coarse aggregate, fine aggregate and cementitious material (cement + mineral admixture) to the horizontal shaft forced concrete mixer in sequence, pre-mix for 1 minute, and after mixing evenly, start the formal mixing, and add them separately during the mixing process. Water and pre-prepared graphene oxide / polycarboxylate superplasticizer (graphene oxide / polycarboxylate superplasticizer is obtained after blending graphene oxide and admixtures for 60min ultrasonically), and the stirring time is...

Embodiment 3

[0039] A high-density anti-freezing and seepage marine concrete is prepared by the following method:

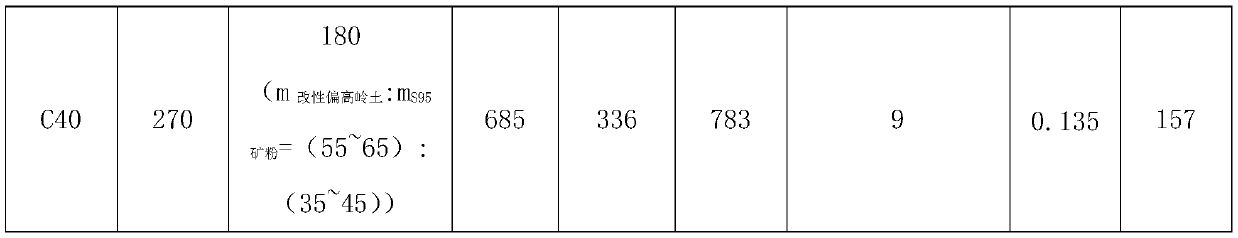

[0040] (1) The distribution ratio of each group is shown in Table 4 below;

[0041] Table 4 Optimized mix ratio (kg / m 3 )

[0042]

[0043] The raw materials for preparing concrete were sampled according to the proportions shown in Table 4, and were produced with reference to the standard of GB / T 50081 "Standard for Mechanical Properties of Ordinary Concrete". Add coarse aggregate, fine aggregate and cementitious material (cement + mineral admixture) to the horizontal shaft forced concrete mixer in sequence, pre-mix for 1 minute, and after mixing evenly, start the formal mixing, and add them separately during the mixing process. Water and pre-prepared graphene oxide / polycarboxylate superplasticizer (graphene oxide / polycarboxylate superplasticizer is obtained after blending graphene oxide and admixtures for 60min ultrasonically), and the stirring time is controlled at 3mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sand rate | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com