Manufacturing method for multi-core optical fiber preform

A manufacturing method and technology of multi-core optical fiber, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of cumbersome preparation process, unstable mutual interference prevention between core layers, etc., and achieve mature process route, important application value, and easy batch production The effect of chemical production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

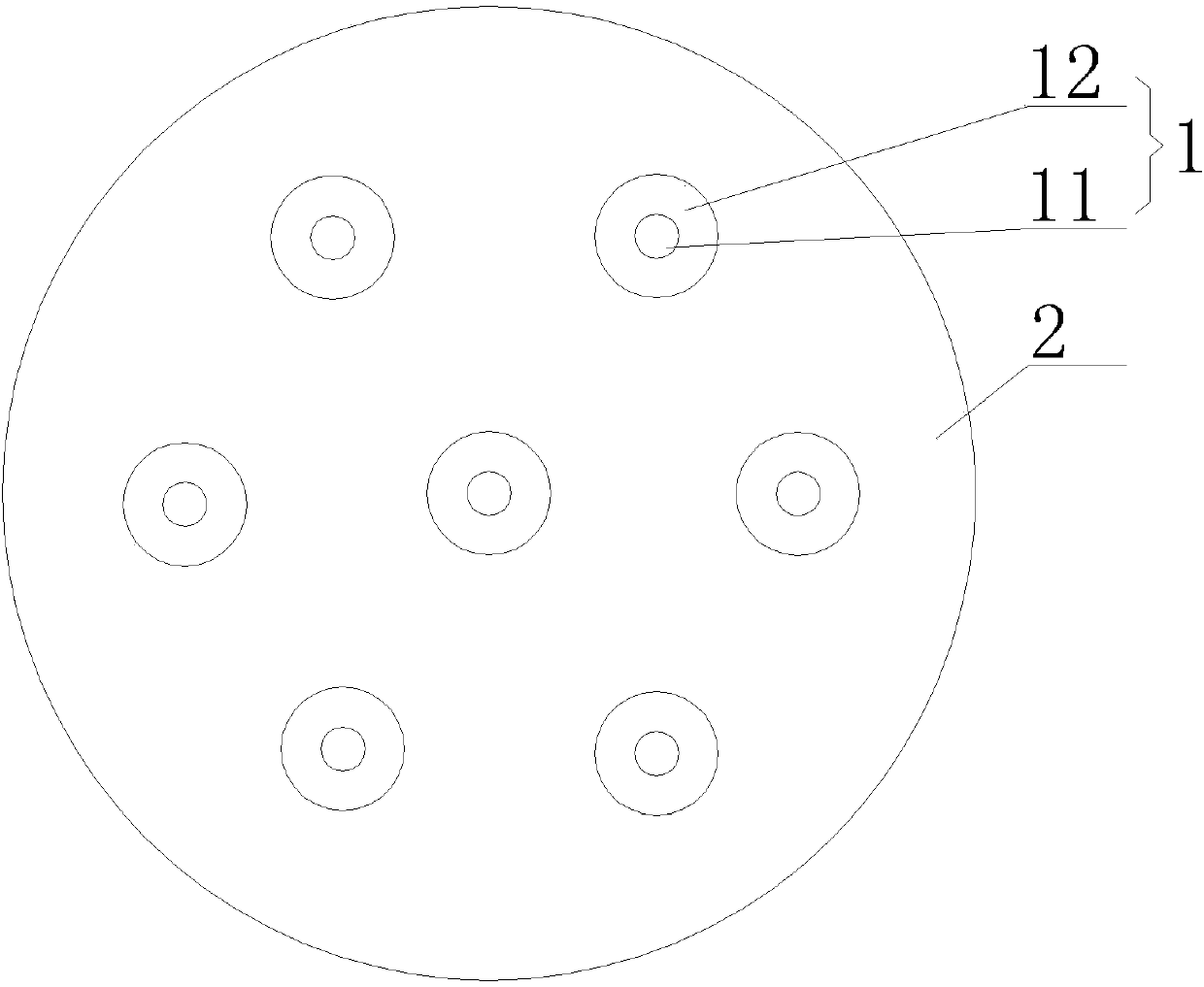

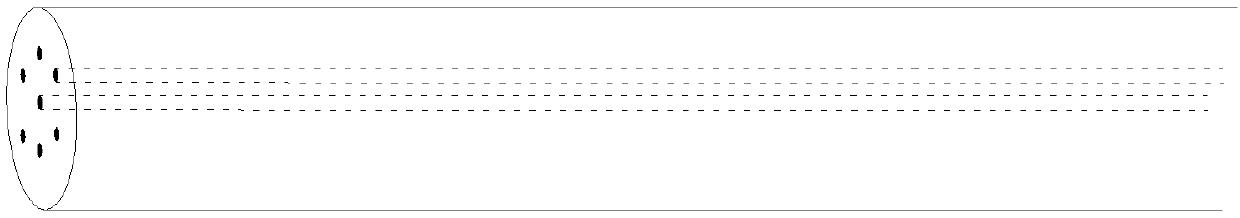

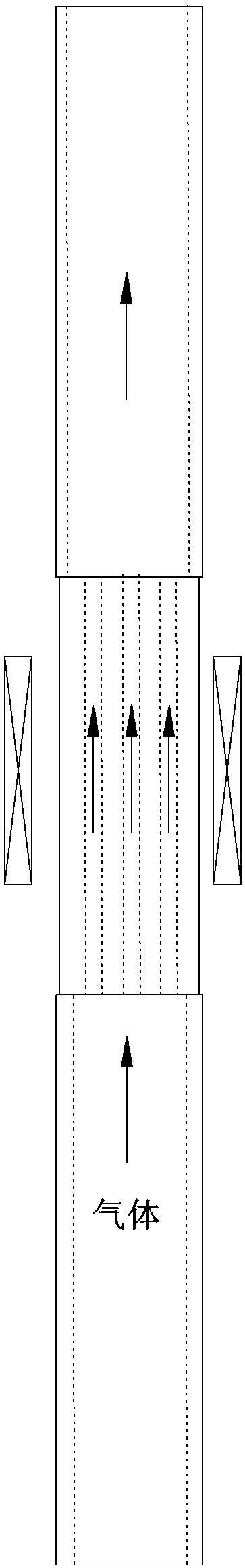

[0024] A method of manufacturing a multi-core optical fiber preform, see Figure 1-Figure 3 : Make fiber core 1 and preform cladding layer 2 respectively, fiber core 1 includes core 11 and core cladding layer 12, wherein core 11 is prepared by chemical vapor deposition VAD process and doped with germanium; core cladding layer 12 is prepared by VAD process, Then, the core 11 and the core cladding layer 12 are melted and shrunk to form the fiber core 1, and then the fiber core 1 is inserted into the corresponding deep hole in the preform cladding layer 2.

[0025] In a specific embodiment:

[0026] In the preparation of the fiber core, after depositing the germanium-doped core by VAD, it is assembled and extended with the fluorine-doped cladding to obtain the fiber core, and the diameter of the obtained fiber core is 12mm-14mm;

[0027] The refractive index difference between the germanium-doped core and the fluorine-doped core cladding layer is 0.0070-0.0080;

[0028] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com