Novel metal floor tile

A new type of metal technology, applied in the direction of floors, pavements paved with prefabricated blocks, roads, etc., can solve the problems of low wear resistance, high cost, easy to cause accidents, etc., to improve strength and service life, reduce laying cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

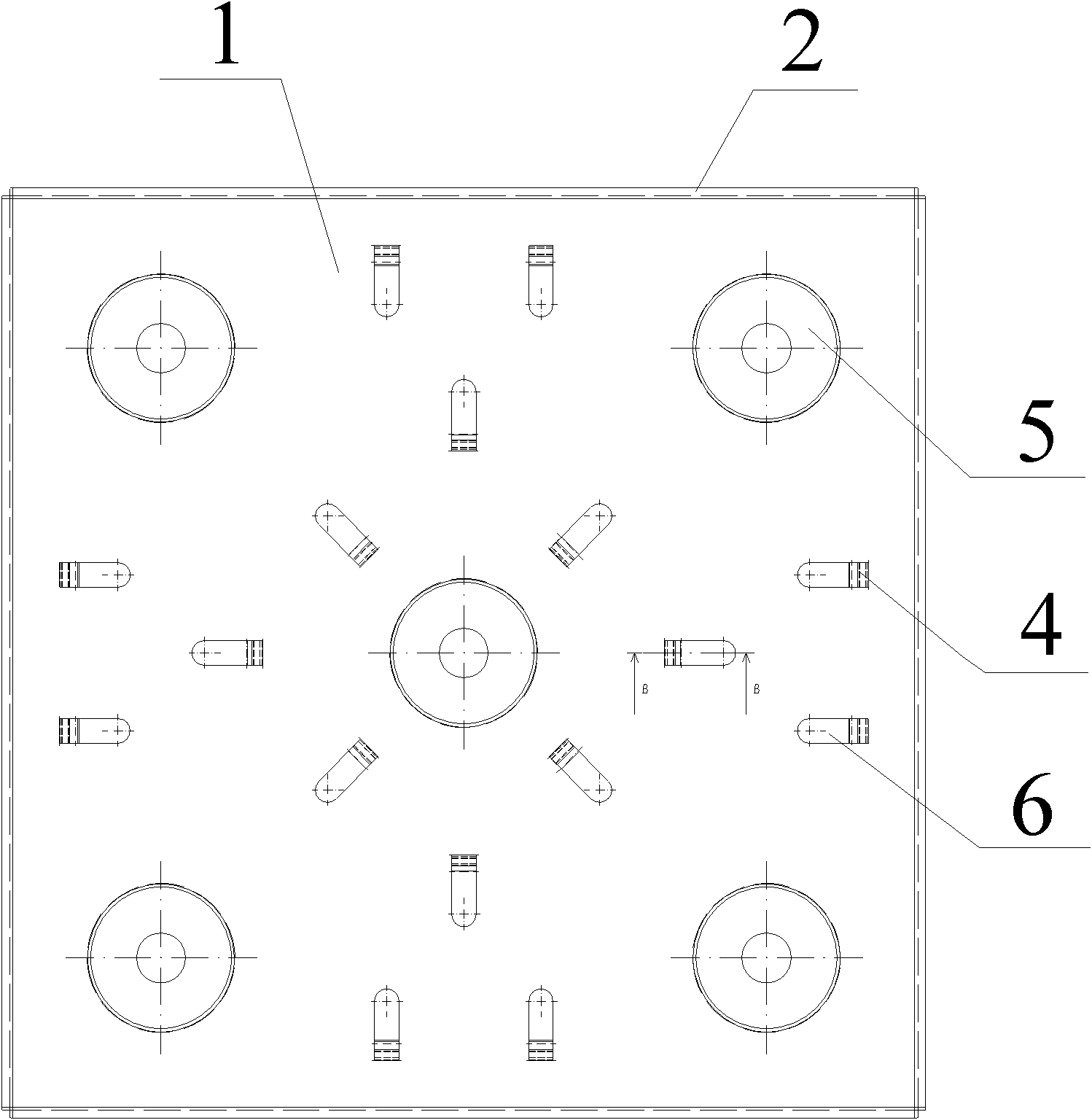

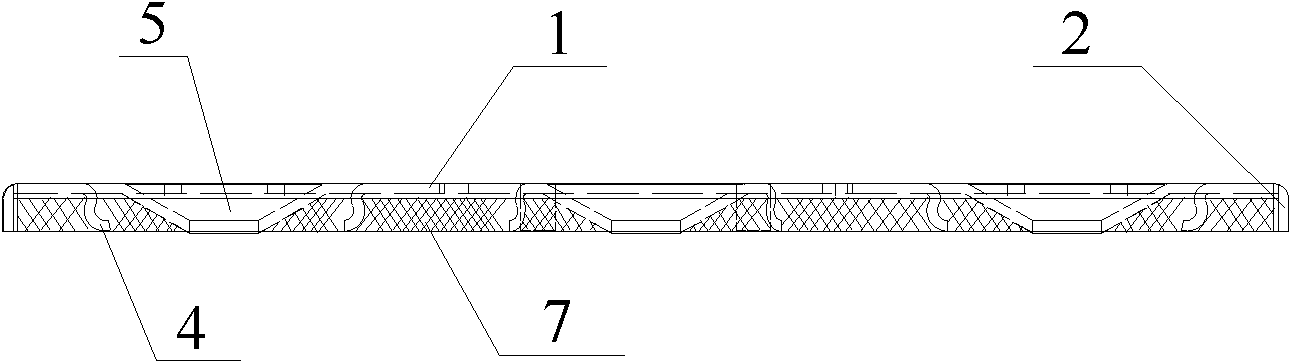

[0044] Metal floor tiles, the structure of which is as Figure 1~2 shown. The metal floor tiles can be fixed by bolts when laying, and are composed of a panel 1 and a frame edge 2 bent downwards around the panel 1 and a filler 7. The panel 1 and the frame edge 2 are made of steel plates, stainless steel plates, copper plates, Made of aluminum sheet or cast iron. The panel 1 is square, and the bending angle with the frame edge 2 is 90 degrees. According to the size, 8 to 46 openings 6 and 5 to 12 counterbores 5 for fixing bolts can be provided on the panel 1. In this embodiment, 16 openings 6 are provided on the panel 1, and counterbores 5 are provided 5, the shape of the opening 6 is a combination of squares and circles, and one end is downward to form an anchor strip 4 connected to the panel 1. The angle between the anchor strip 4 and the panel 1 is 30-90 degrees, and the longitudinal section of the anchor strip 4 is half Circular, approximately semicircular arc, S-shape c...

Embodiment 2

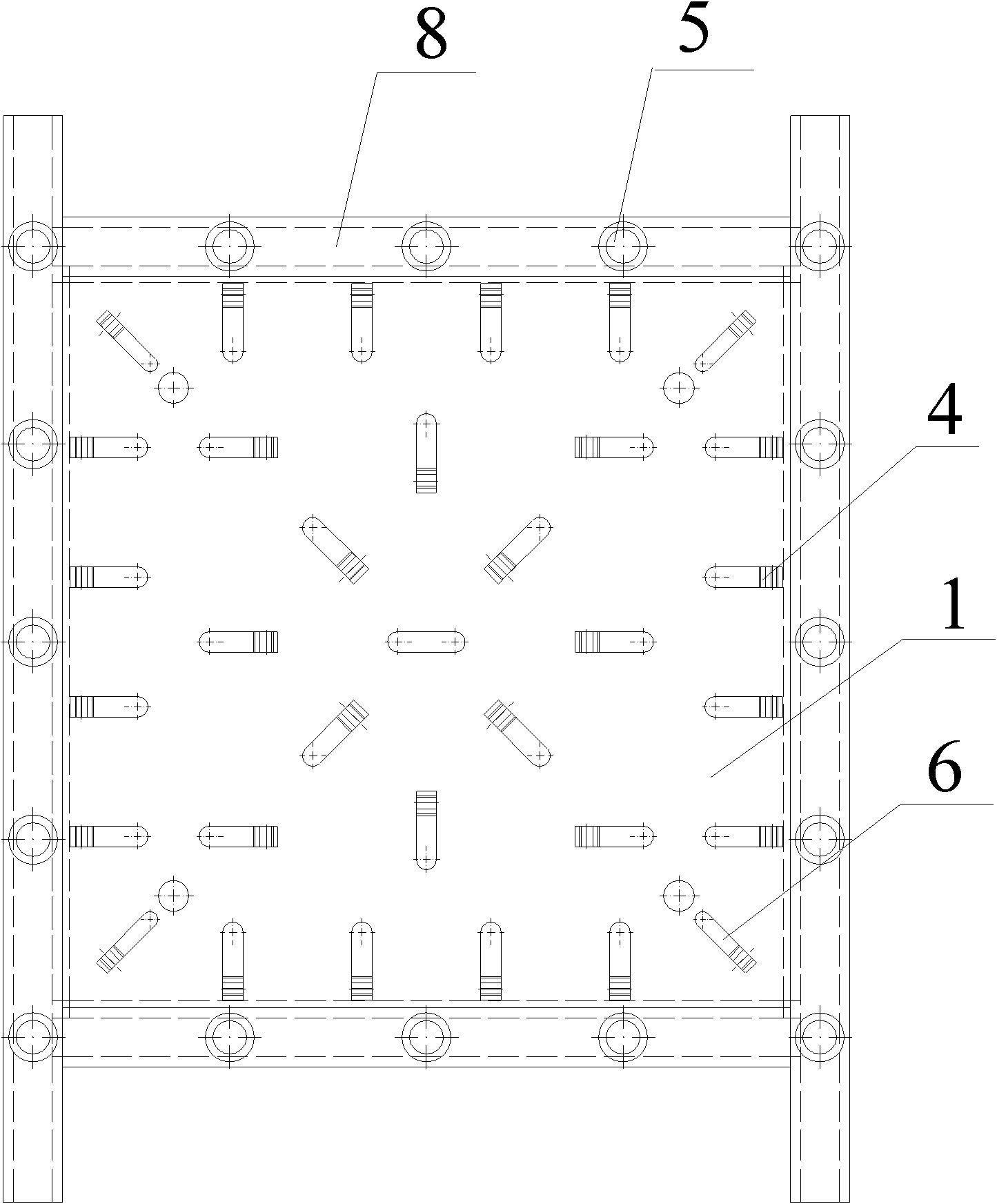

[0047] Metal floor tiles, the structure of which is as Figure 3-4shown. This metal floor tile can adopt the structure that bead 8 and bolt are fixed when laying, and is made up of panel 1 and the frame edge 2 that is formed by bending downwards around this panel 1 and filler 7, the adoption of panel 1 and frame edge 2 (plating Steel plate with zinc layer) stainless steel plate, copper plate, aluminum plate, steel plate or cast iron. The panel 1 is square, and the bending angle with the frame edge 2 is 90 degrees. 8 to 46 openings 6 can be set on the panel 1 according to the size. In this embodiment, there are 32 openings 6 on the panel 1. The shape of the openings 6 is a combination of square and circle. 1 is connected to the anchor strip 4, the angle between the anchor strip 4 and the panel 1 is 90 degrees, and the longitudinal section of the anchor strip 4 is semicircular, approximately semicircular arc, two semicircular or approximately semicircular S-shape, multiple S-...

Embodiment 3

[0051] A prefabricated metal floor tile that is laid and installed on the floor of the site. The metal material of the floor tile can be made of steel plate, stainless steel plate, copper plate, aluminum plate, or cast iron. It is selected according to different operating methods in the production workshop. The foundation of the floor The material conventionally used is cement or other mixtures of cement mixes.

[0052] Its structure of the metal floor tile of the present embodiment is as Figure 6~7 As shown, the laying method is used to lay on the ground. It is composed of a panel 1 and a frame edge 2 around it. The bending angle between the panel and the frame edge is 90 degrees. The panel 1 is square or rectangular and has 46 openings 6. The shape of the hole 6 is square, circular or a combination of squares and circles. One end of the opening 6 is downward to form an anchor strip 4 connected to the panel 1. The angle between the anchor strip 4 and the panel 1 is 30-90 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com