Coaxially-packaged DFB laser transmitter with refrigeration function

A technology of laser emitters and packaging tapes, which is applied in the direction of lasers, phonon exciters, laser components, etc., can solve the problems of difficult to achieve wavelength division multiplexing long-distance transmission, no temperature control, large packaging size, etc., to achieve suppression Chirp effect, precise temperature control, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

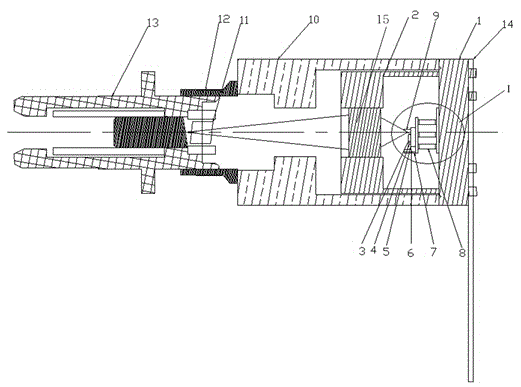

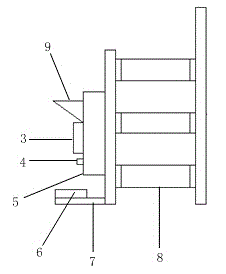

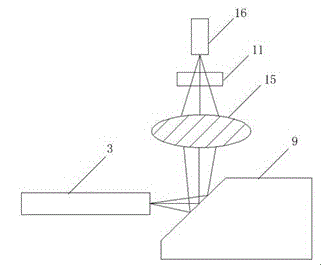

[0017] Such as figure 1 , 2 As shown, the present invention adopts a TO-8 package structure, mainly including a tube base 1, a tube cap 2, a DFB laser chip 3, a thermistor 4, a laser chip heat sink 5, a backlight detection chip 6, a detection chip heat sink 7, a thermoelectric Refrigerator 8, 45° full reflection film 9, housing 10, optical isolator 11, metal sleeve 12, adapter 13, soft belt 14 and lens 15. The cavity of the laser transmitter is composed of a tube base 1, a housing 10 and an adapter 13, and the tube base 1 needs to meet the 10G communication transmission rate. The DFB laser chip 3 is mounted on the laser chip heat sink 5 through gold selenium solder, and the backlight detection chip 6 is mounted on the detection chip heat sink 7 through epoxy glue. The tube base 1, tube cap 2, optical isolator 11, adapter 13 and 45° full reflection film 9 in the cavity are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com