Uneven settlement reinforcing leveling repairing method for existing building floors

A technology of existing buildings and repair methods, which is applied in the field of uneven settlement reinforcement and leveling repair of existing buildings, and can solve the problems of uneven penetration of grout, damage to equipment and goods, large difference between expansion and original volume, etc. problems, to achieve the effect of reducing the use of grouting equipment, improving stability and durability, and improving construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings. The words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top", "inner " and "outward" refer to directions toward or away from the geometric center of a particular part, respectively.

[0045] The method of strengthening, leveling and repairing the uneven settlement of the existing building floor, the steps are as follows:

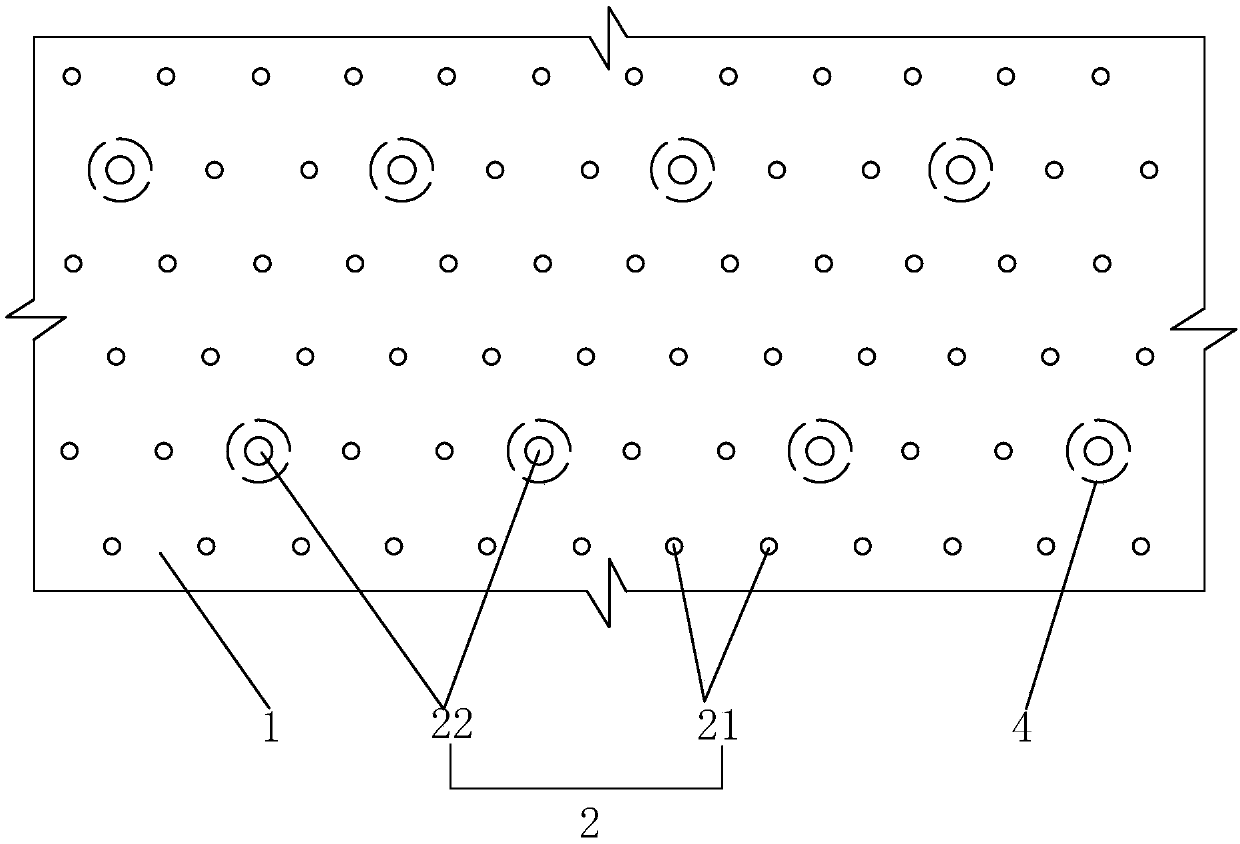

[0046] S1 as figure 1As shown, the grouting holes 2 are arranged along the floor 1. The grouting holes 2 include shallow grouting holes 21 and deep grouting holes 22. The diameter of the grouting holes 2 is 42-52mm. All grouting holes 2 are arranged in a quincunx pattern, and all grouting deep holes 22 are also arranged in a quincunx pattern. The distance between the centers of adjacent grouting holes 2 is 2-4m, and the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com