A kind of processing method of dietary fiber nanoemulsion coating film for fish floss

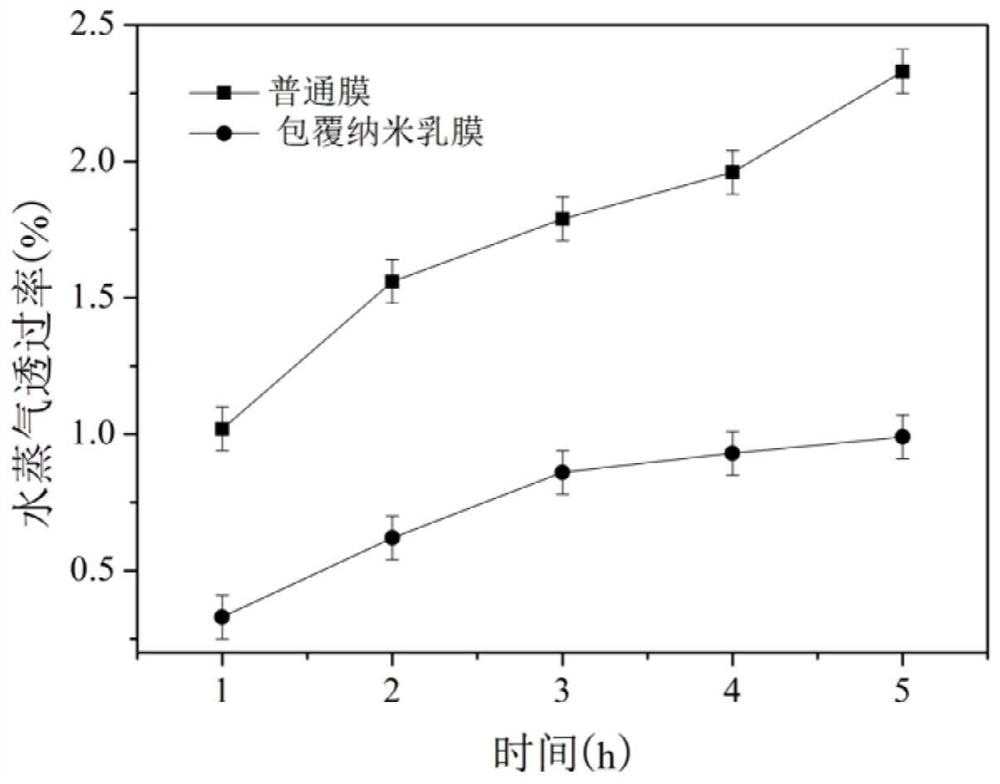

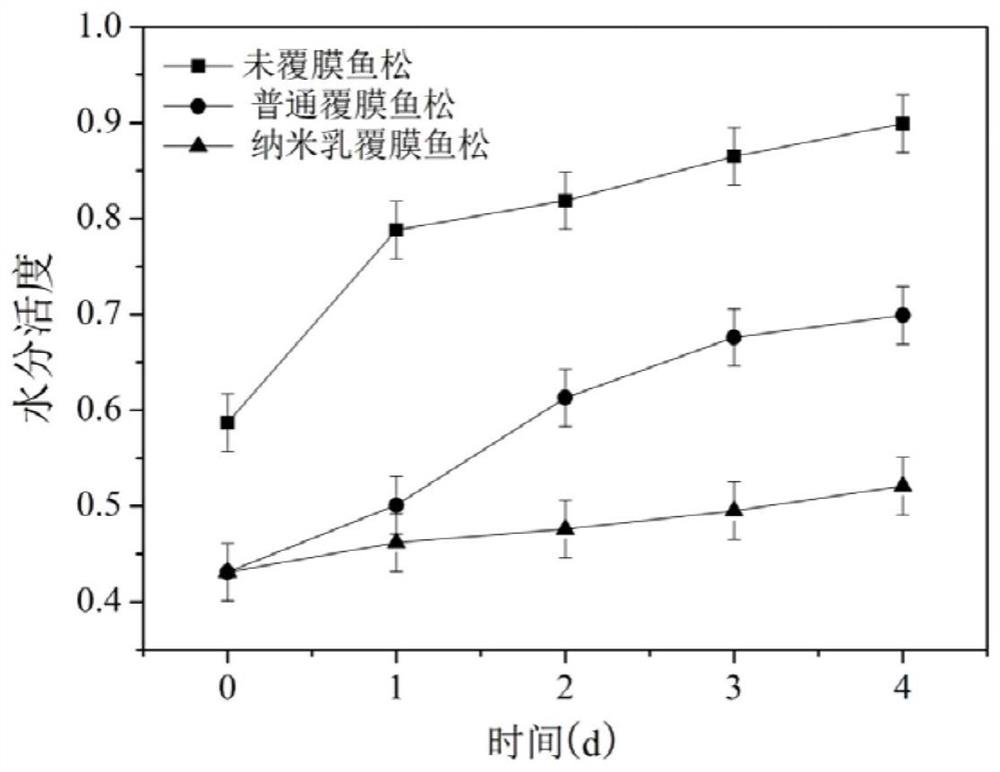

A technology of dietary fiber and processing method, which is applied in the processing field of coating film for fish floss, can solve the problems of unsatisfactory anti-oxidation ability and water blocking effect, low mechanical properties, easy to produce cracks, etc., and achieves good water vapor transmission. rate and moisture control ability, improve mechanical properties, avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of nanoemulsion in described step 2. comprises the following steps:

[0041] ① Mix and stir glyceryl monocaprylate and Span 80 at a mass ratio of 7:3 to obtain oil phase D;

[0042] ② Slowly add 1 mL of tea polyphenols dropwise to 9 mL of D oil phase, and stir at room temperature at 900 rpm for 20 minutes. The content of the tea polyphenols is 25 mg / mL to obtain E mixture;

[0043] ③Prepare 60mL of a mixed solution containing 0.07% sodium alginate, 3% Tween 80 and 0.06% SDF, then mix and stir the solution at a speed of 600rpm, and add E mixture dropwise at a speed of 1mL / min during the stirring process , to get the F mixture;

[0044]④ Ultrasonic homogenize the mixed solution F for 2 minutes to obtain the mixed solution f1; then add 1 mL of 0.1% calcium chloride solution dropwise to the mixed solution f1, and stir at a speed of 600 rpm for 30 minutes to obtain the mixed solution f2; 4 mL of chitosan with a concentration of 0.06% was put into the...

experiment example 1

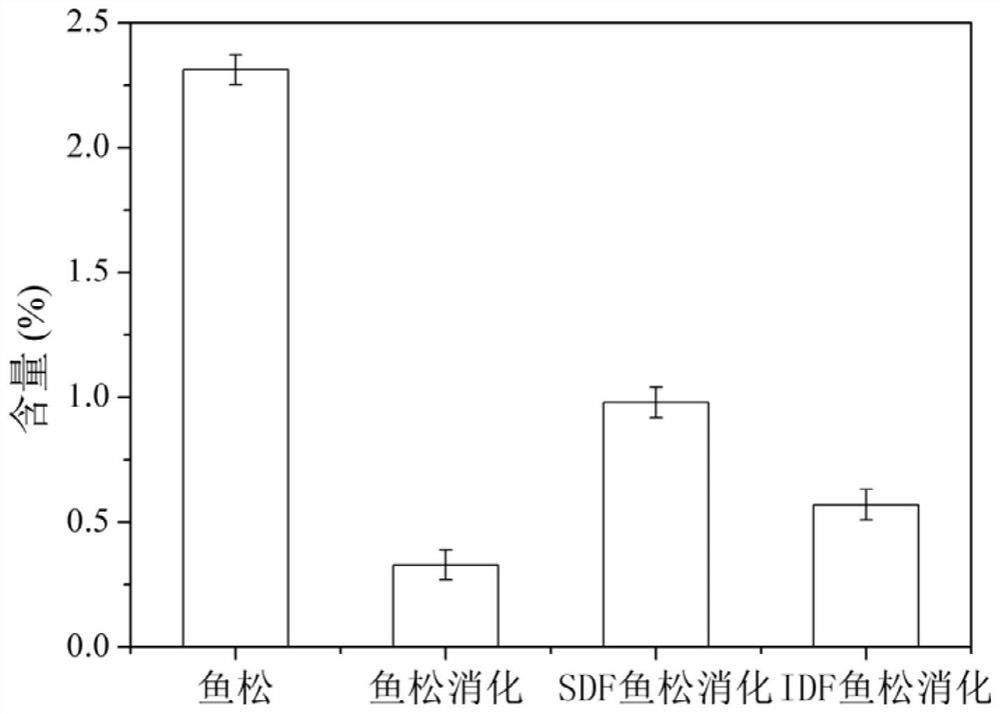

[0052] Experimental Example 1: After soaking the wheat bran raw material in water for 15 minutes at a mass ratio of 1:10, it was centrifuged and dehydrated three times, and after each centrifugation, the upper layer of starch and protein was removed to obtain a precipitate; then the precipitate was mixed with Water is mixed at a mass ratio of 1:10, and the pH is adjusted to 5.5 with 1mol / L citric acid, and then placed in a constant humidity incubator at 55°C to decompose phytic acid for 5 hours and then washed to neutrality; then placed at 55°C ℃ in a constant temperature drying oven for 8 hours; to obtain 100 mesh wheat bran powder. Then the wheat bran powder and the H powder prepared by the step of the present invention are processed according to steps ③-⑥ in the preparation method of pure SDF respectively to obtain the IDF of wheat bran, the pure product of SDF and the IDF, Pure SDF. Then carry out component analysis identification to 4 parts of pure products, the result i...

experiment example 2

[0056] Experimental Example 2: The pure wheat bran SDF and mung bean skin SDF pure products obtained in Experimental Example 1 were used as experimental products, and the 2,2'-diphenyl-1-picrylhydrazine (DPPH ), 2,2-azinobis-3-ethylbenzothiazoline-6-sulfonate (ABTS·+) and hydroxyl radical (·OH) scavenging ability. The method of measuring DPPH free radicals is: take 1 mg / mL of SDF extract and DPPH ethanol solution (6×10-5M) in a ratio of 1:4 and mix them at room temperature for 20 minutes in the dark and then measure the absorbance at 517nm. A calibration curve was constructed using vitamin C (VC) as a comparison, and the results were expressed as VC equivalents.

[0057] The method of measuring ABTS·+ free radicals is: mix each 7.0mM ABTS·+ solution and 4.95mM potassium persulfate solution at a volume ratio of 1:2, and react in the dark for 12 hours at room temperature to obtain the ABTS·+ stock solution. Then dilute the ABTS·+ stock solution with 80% ethanol so that the abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com