Method for changing applied force state of pile

A technology of stress state and power, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve problems such as increased cost, high safety factor, and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

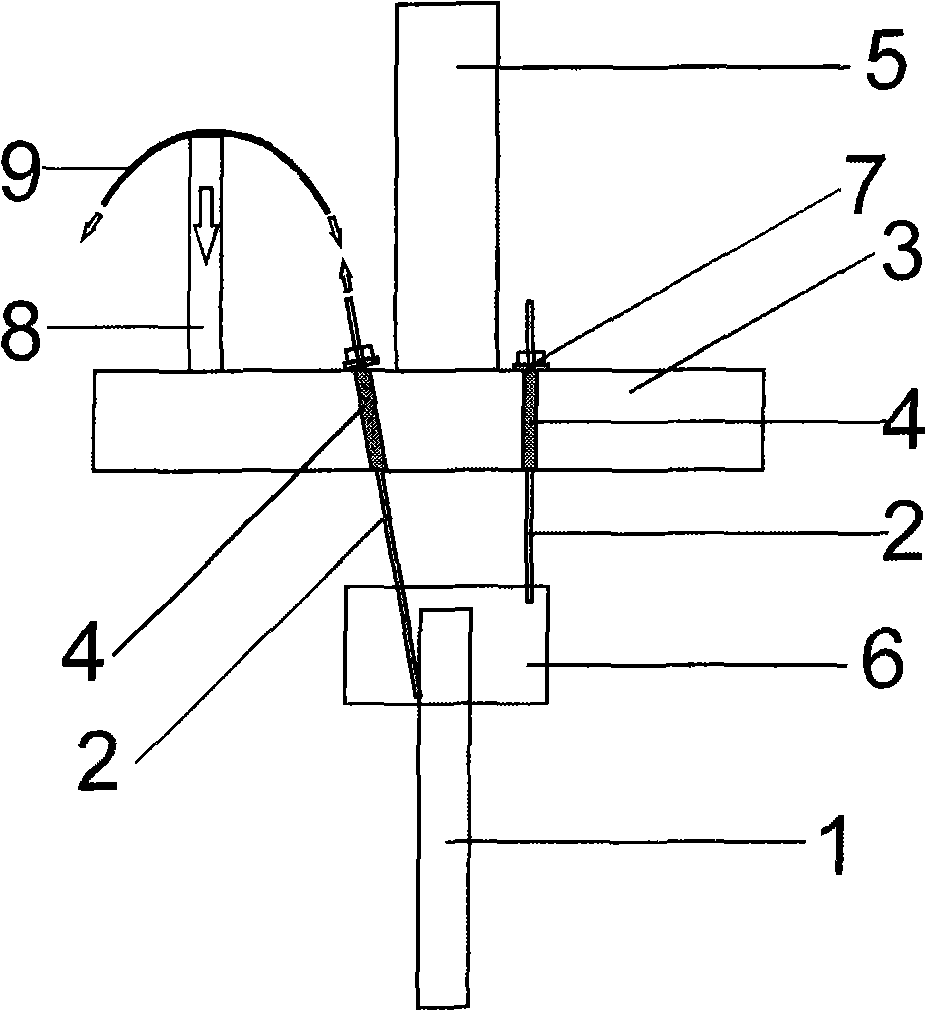

[0013] Embodiment 1: see attached figure 1

[0014] The member (2) connected to the pile (1) extending out of the pile passes through the hole (4) provided in the cap (foundation bottom plate) (3), and extends to the top of the cap (foundation bottom plate) (3), Thereby, a space for operation is provided for tensioning or compressing the member (2) protruding from the pile. The member (2) protruding from the pile is fixed through the hole, or fixed after a set tension or compression operation procedure, and the load is transferred to the pile (1) through the member (2) protruding from the pile, so that the load The transmission path of the pile (1) and the stress state of the pile (1) change. The supporting anchor point (8) of the equipment used for tension or compression is not set directly above the pile (1), and the pile (1) can bear The load of the pile is shared to the surrounding area, or the load of the surrounding area is concentrated on the pile (1), thereby affec...

Embodiment 2

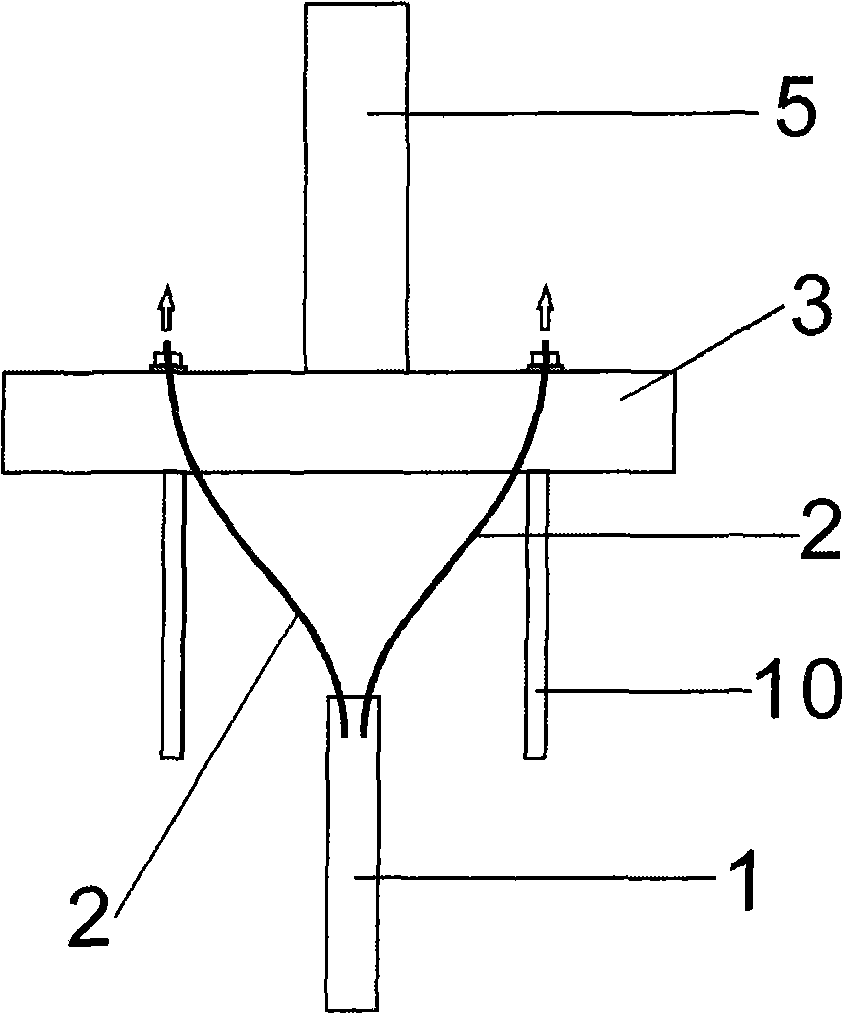

[0015] Embodiment 2: see attached figure 2

[0016] Set hoops (10) in the upper and lower set height ranges on the side of the pile head, or set auxiliary piles (10) around the pile (1), place shock absorbing devices, displacement The adjustment device is filled with gravel, sand, fly ash, rubber, foam plastic and other materials of different materials and their combinations or reserved clearance according to the needs. The hoop (10) and the pile (1) are one pile (1) and one hoop One in four forms such as (10), many piles (1) one hoop (10), one pile (1) many hoops (10), many piles (1) and many hoops (10). The effect of the hoop is many, and in the method of the present invention, use the hoop mainly because the hoop can share the load of the pile. The distance of groundwater seepage is increased, and the pressure of water stop and seepage prevention caused by opening holes on the cap (foundation floor) is reduced. In addition, the position of hoops or auxiliary piles is als...

Embodiment 3

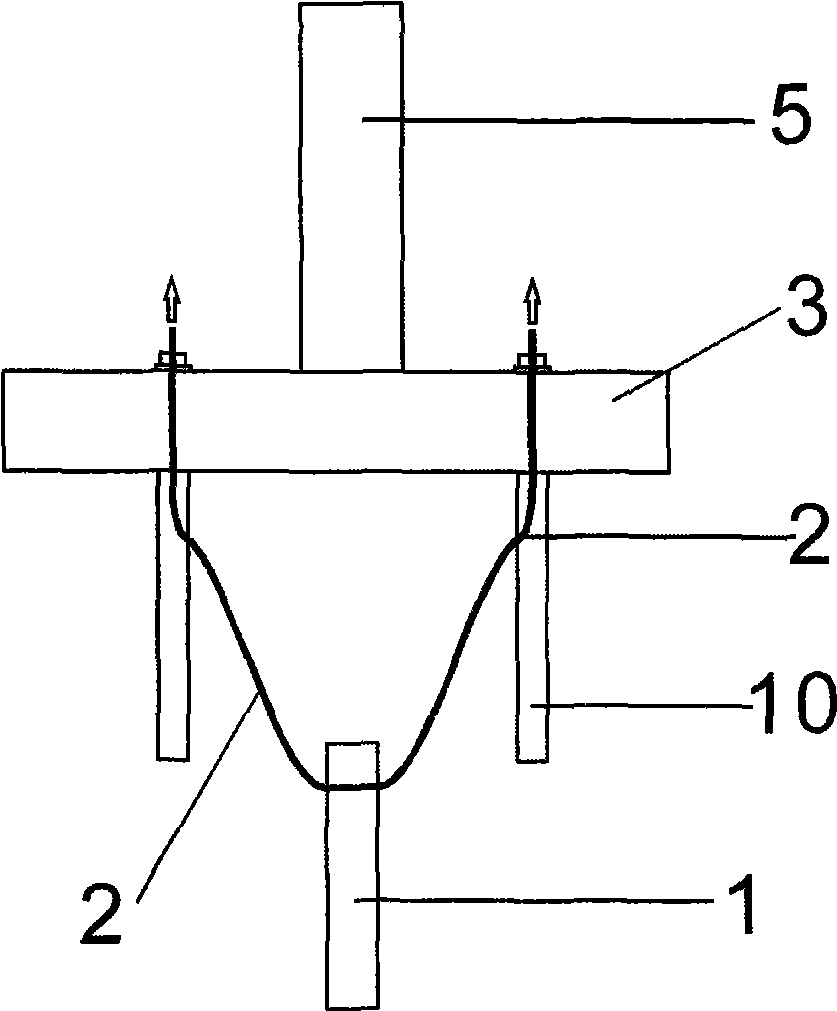

[0017] Embodiment 3: see attached image 3 , attached Figure 4

[0018] A hole (4) is set in the hoop or auxiliary pile (10) so that the member (2) protruding out of the pile passes through, or the member (2) protruding out of the pile nearly horizontally is directly connected to the hoop or auxiliary pile (10) ) to fix. The member (2) protruding out of the pile is directly fixed on the hoop or the auxiliary pile (10) close to the horizontal, and is directly fixed on the cap (foundation floor) close to the vertical, and the effect is very different. In the absence of holes (4), if the cross-section and strength of the components protruding from the pile are relatively large, and they are directly fixed on the cap (foundation floor) close to vertical, then it should be regarded as the pile top itself. Or shock-absorbing device, displacement adjustment device; if the components protruding from the pile are slender steel bars and steel strands, and are directly fixed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com