Railway traffic cross-sea segment concrete

A technology of rail transit and concrete, which is applied in the field of rail transit cross-sea segment concrete, and can solve the problems of no concrete base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

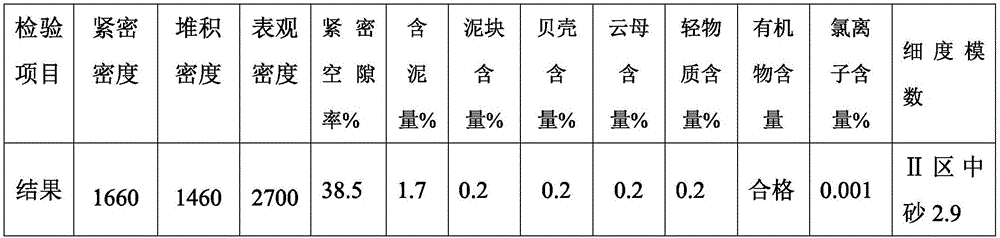

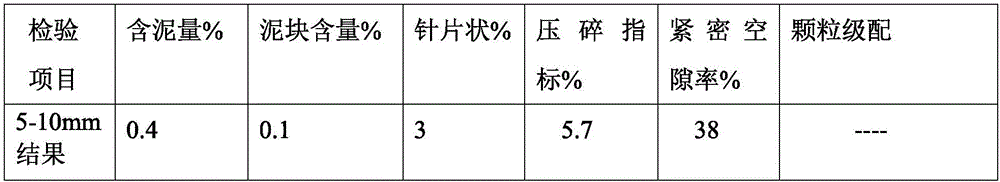

[0031] For rail transit cross-sea segment concrete, the sand rate is 36%, and the specific mix ratio is as follows:

[0032]

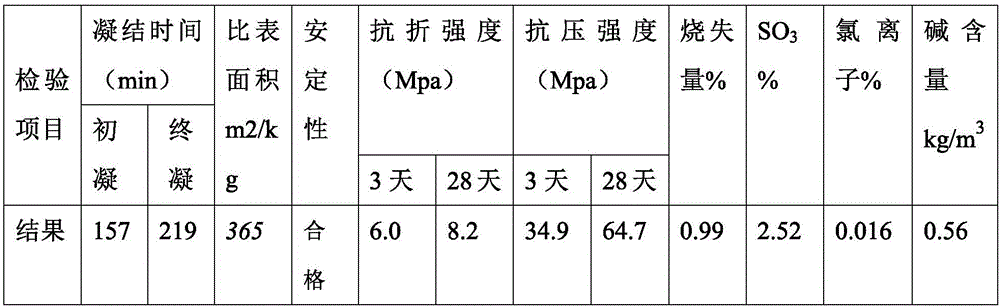

[0033] Mix the above-mentioned components uniformly to make concrete slurry, and place it in a segment mold for molding. The performance indicators of the prepared concrete are as follows:

[0034]

[0035] The specific method for preparing the cross-sea segment concrete for the above-mentioned rail transit cross-sea segment is as follows: the raw material components that have passed the inspection are sent to the mixer through the metering equipment automatically controlled by a computer, and then mixed evenly to form a concrete mixture. And placed in the segment mold molding. Through the technical process of one-time dough collection, resting, second-time dough collection, steam curing, mold removal, water curing for 7 days and natural curing for more than 28 days, the cross-sea view sheet is obtained.

[0036] The segments prepared from the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com