Automobile ABS mounting bracket

A technology for mounting brackets and automobiles, which is applied to vehicle parts, transportation and packaging, etc. It can solve problems affecting assembly speed and effect, difficult manufacturing and processing, complex shape and structure, etc., and achieve the effects of saving assembly time, easy processing, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

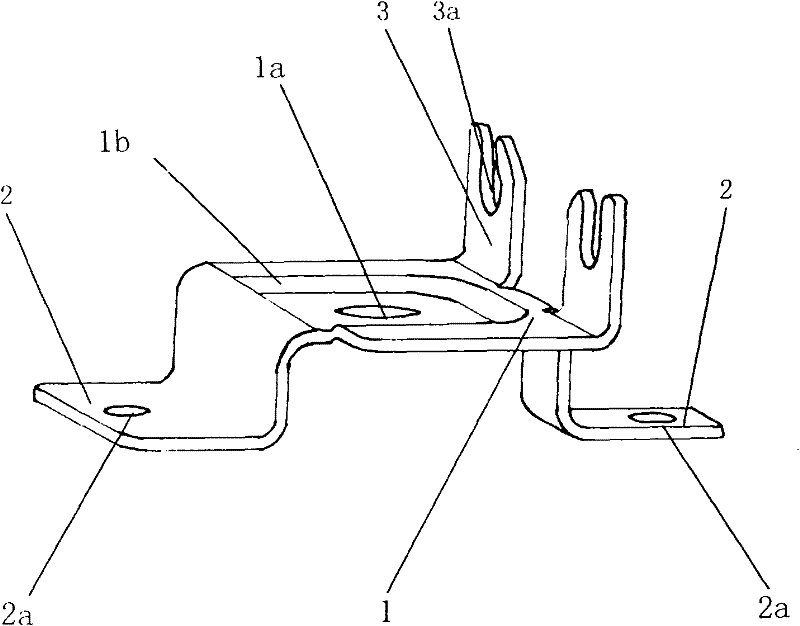

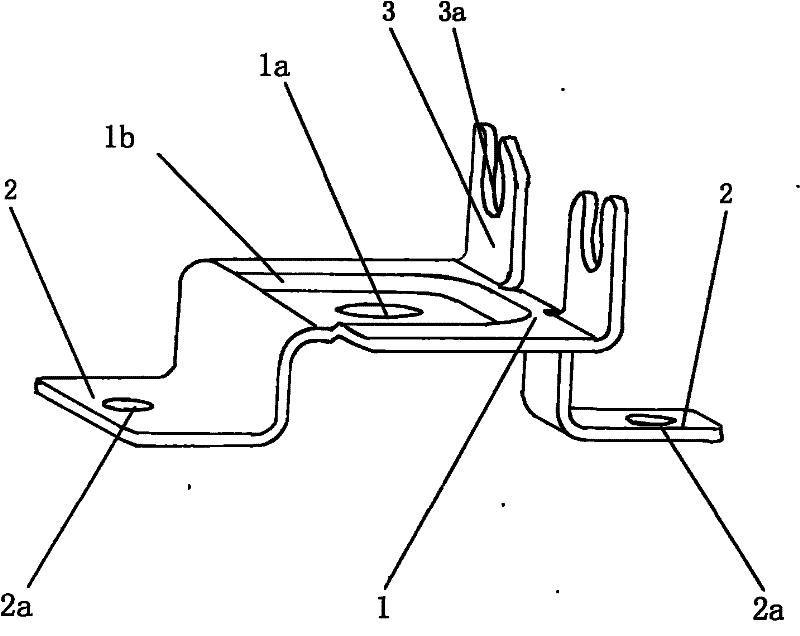

[0018] see figure 1 , The automotive ABS mounting bracket includes an ABS actuator positioning surface 1, a bracket mounting surface 2 and an ABS actuator mounting surface 3, and the three parts are formed by a plate. The mounting surface of the bracket is respectively connected to the left and right sides of the positioning surface 1 of the ABS actuator, and extends downward and then protrudes outward, forming an L-shape, forming an approximate "J"-shaped structure with the positioning surface 1 of the ABS actuator. Mounting holes 2a are provided on the mounting surface of the bracket. The ABS actuator mounting surface 3 is respectively connected to the two sides on the right side of the ABS actuator positioning surface 1 and extends vertically upwards, and the opening of the mounting groove 3a at the top of the ABS actuator mounting surface 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com