Structure with prefabricated composite insulation board mounted by anchor bolts

A composite thermal insulation and anchor bolt technology, applied in thermal insulation, building thermal insulation materials, building components and other directions, can solve the problems of poor fire resistance of steel, easy corrosion of thermal insulation layer, poor durability, etc. Good performance and good fireproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

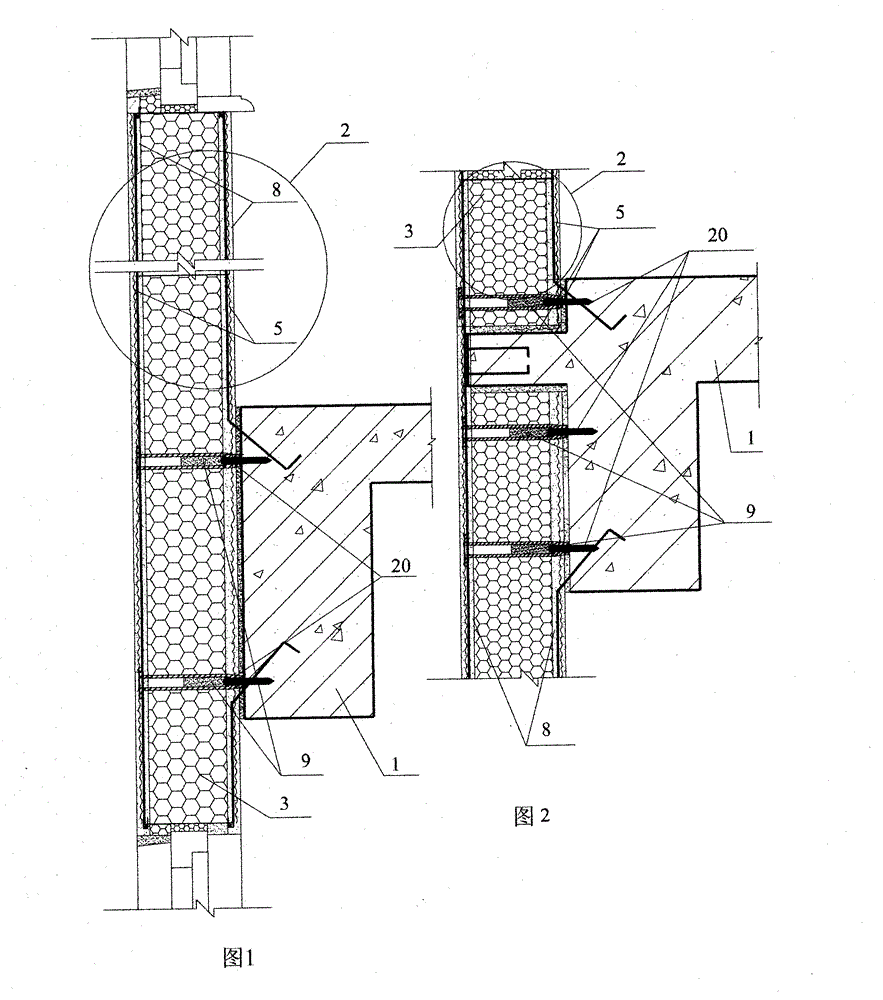

[0015] Implementation mode one: see figure 1 , figure 2 , a structure for installing prefabricated composite thermal insulation boards with anchor bolts in this embodiment, which is composed of building main structure 1, prefabricated composite thermal insulation boards 2, and anchor bolts 20; The structure 1 is fixed, and there is a fireproof material in a certain range of the protective layer 8 at the outer end of the anchor bolt 20 or / and within a certain range on the surface, forming a structure in which the anchor bolt is used to install the prefabricated composite insulation board;

[0016] The prefabricated composite insulation board 2 includes prefabricated composite insulation boards of various structures; the prefabricated composite insulation board 2 is composed of an insulation layer 3, a protective layer 8, a mesh tensile material 5, and cement polymer mortar 4. The prefabricated composite insulation board There are steel bars or no steel bars in 2; the thermal ...

Embodiment approach 2

[0024] Implementation mode two: see figure 1 , figure 2 The difference between this embodiment and Embodiment 1 is that in this embodiment, an alkaline material 9 is injected into the casing of the anchor bolt 20, and the alkaline material 9 protects the nails or other steel connectors in the anchor bolt 20 to increase corrosion resistance. performance.

[0025] The thickness of the galvanized layer of nails is limited. When using nail-type plastic anchors, inject alkaline materials into the plastic casing, such as cement polymer mortar, and then plug the outer end with insulation materials to ensure that the durability will not last. Less than 50 years, very convenient and low price.

[0026] Explanation about the present invention:

[0027] Protective layer 8 of the present invention is modified cement mortar or modified concrete layer, including the following meanings:

[0028] 1. Including cement mortar or modified concrete modified by adding additives, fly ash, stone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com