Air bag type sealing structure for deformation joint of open trench tunnel

A technology for open-cut tunnels and sealing structures, applied in underwater structures, infrastructure engineering, hydraulic engineering, etc., can solve problems such as difficulty in concrete, water leakage, concrete damage or displacement, and achieve the effect of meeting durability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

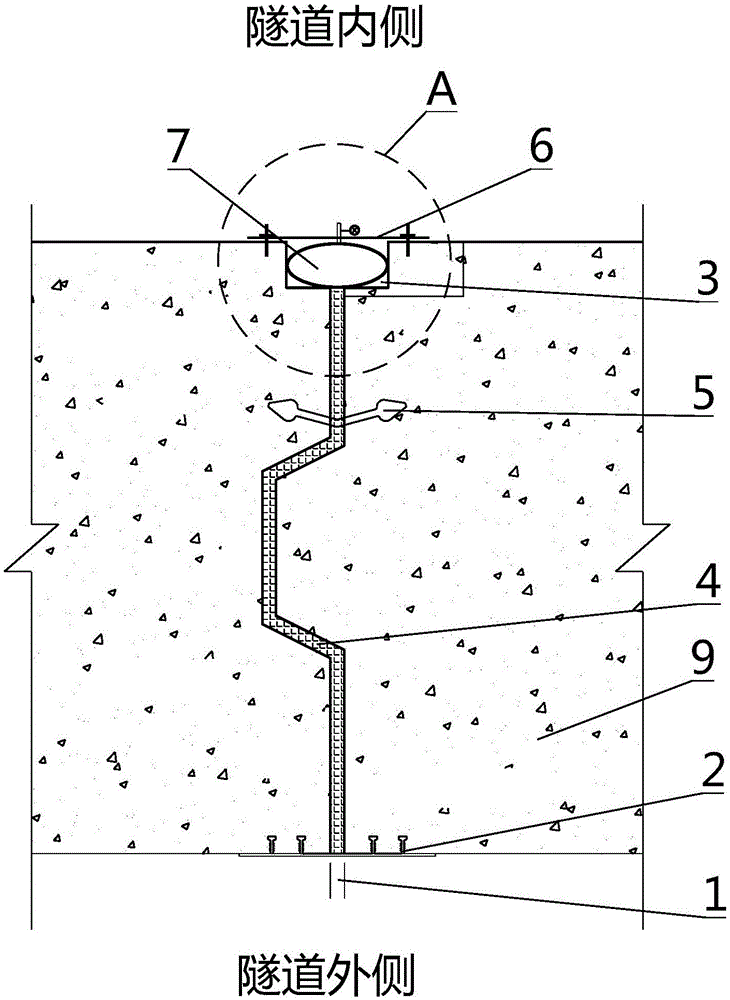

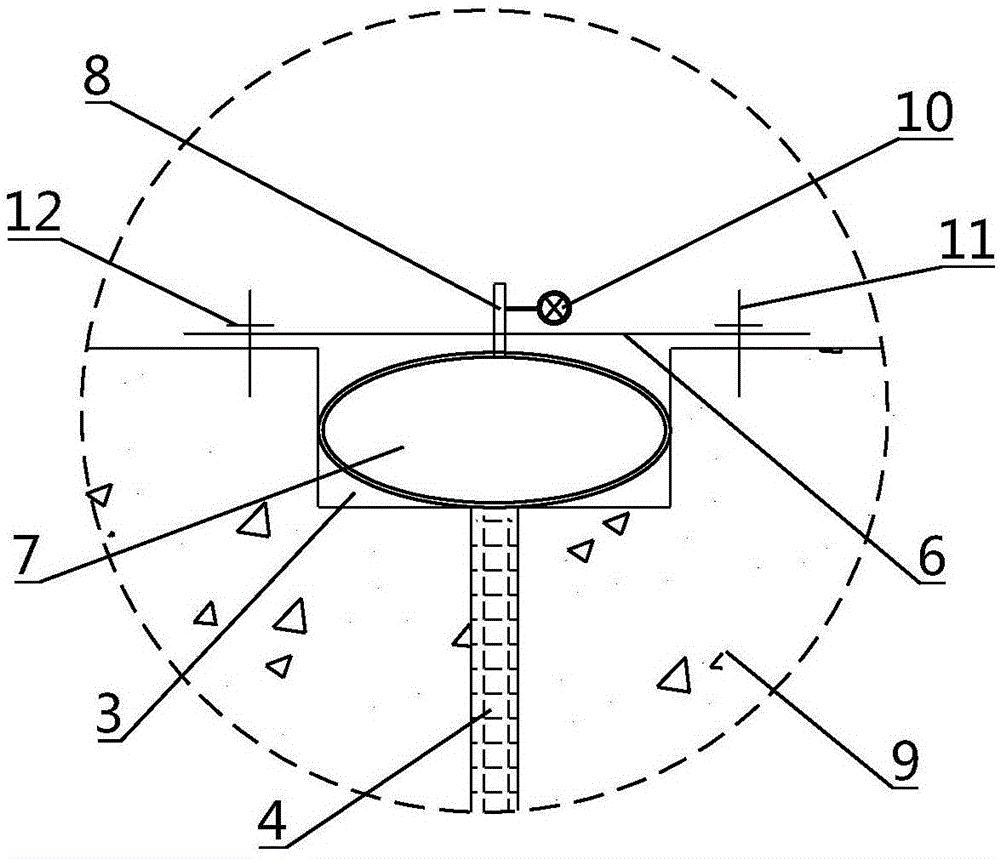

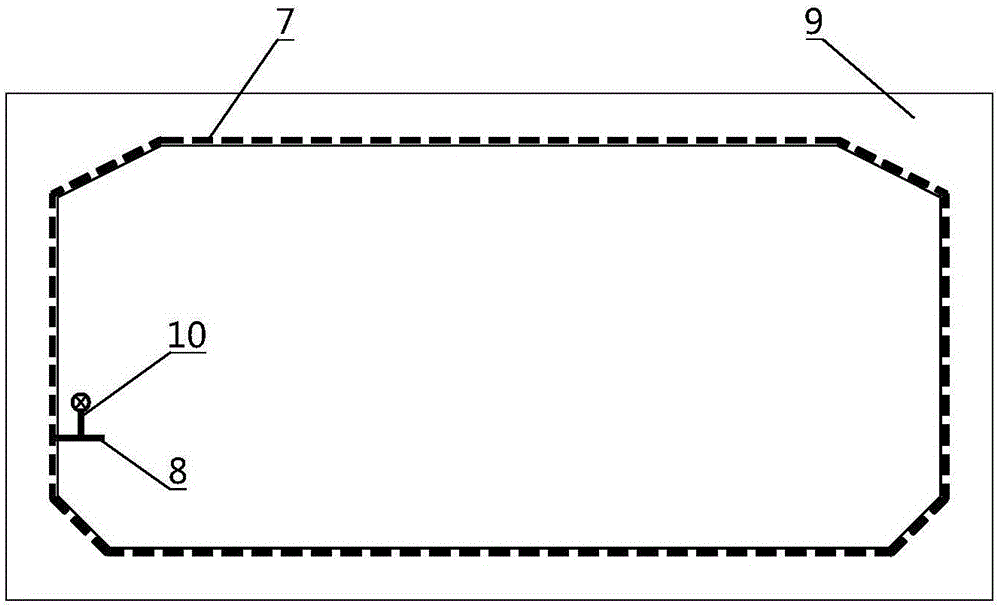

[0020] pass below Figure 1 ~ Figure 3 And the way of enumerating some optional embodiments of the present invention, the technical solution of the present invention (including the preferred technical solution) is described in further detail, and any technical feature and any technical solution in this embodiment do not limit the protection scope of the present invention .

[0021] like figure 1 , figure 2 and image 3 As shown, the sealing structure of the deformation joint of the airbag type open-cut tunnel designed by the present invention is provided with a groove 3 along the circumference of the inner wall of the tunnel at the position of the deformation joint 1 inside the tunnel, and at the position of the deformation joint 1 outside the tunnel. There is a back-adhesive waterstop 2; the deformation seam 1 between the back-adhesive waterstop 2 and the bottom of the groove 3 is filled with filling material 4, and the deformation seam 1 is also provided with an embedded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com