Slurry mineral admixture suitable for special-shaped member concrete, and preparation method thereof

A technology of mineral admixture and special-shaped components, which is applied in the field of building materials, can solve the problems of less than 30% comprehensive utilization rate of steel slag, no report of steel slag, difficult to wear and activation, etc., to meet the requirements of formwork removal strength and durability, reduce Pores and pockmarks, the effect of reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

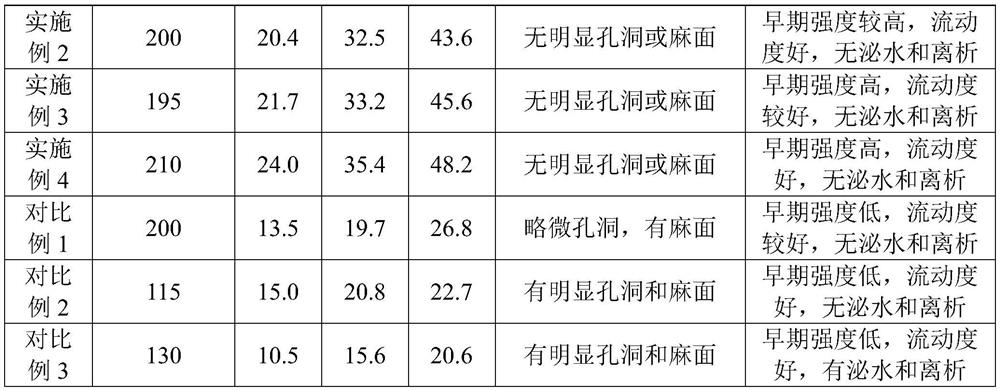

Embodiment 1

[0021] Take 150 parts of massive steel slag (moisture content 10%), 160 parts of slag (moisture content 8%), and crush it to a maximum particle size of 1mm through a jaw crusher. 1 Configuration function 5 parts of admixture and 150 parts of water are placed in a ball mill with a ball ratio of 10 parts with a particle size of 0.6-1.0 mm, 80 parts with a particle size of 1.0-1.7 mm, and 140 parts with a particle size of 1.7-2.5 mm. Grinding for 45 minutes, the median particle size of the obtained slurry mineral admixture is 11.5 μm, mixed with 700 parts of 425 ordinary Portland cement, 750 parts of sand, 1050 parts of crushed stone, 2 parts of polycarboxylate superplasticizer, 140 parts The concrete material was obtained by stirring with water, steamed and cured at 40°C for 8 hours, and after the formwork was removed, the standard curing (20°C, humidity 95%), its performance indicators are shown in Table 1.

Embodiment 2

[0023] Take 180 parts of massive steel slag (moisture content 15%), 200 parts of slag (moisture content 8%), and crush it to a maximum particle size of 1mm through a jaw crusher. 1.5 Configuration function 9 parts of admixture and 180 parts of water are placed in the ball mill with a ball ratio of 15 parts with a particle size of 0.6-1.0 mm, 70 parts with a particle size of 1.0-1.7 mm, and 120 parts with a particle size of 1.7-2.5 mm. Grinding for 60 minutes, the obtained slurry mineral admixture has a median particle size of 9.5 μm, and 850 parts of 425 ordinary Portland cement, 800 parts of sand, 1100 parts of gravel, 5 parts of naphthalene-based water reducer, and 250 parts of water The concrete material obtained by mixing was steamed and cured at 40°C for 8 hours, and after the formwork was removed, it was cured under standard conditions (20°C, humidity 95%), and its performance indicators are shown in Table 1.

Embodiment 3

[0025] Take 160 parts of massive steel slag (moisture content 8%), 180 parts of slag (moisture content 10%), and crush it to a maximum particle size of 1mm through a jaw crusher. 1.3 Configuration function 7 parts of admixture and 170 parts of water are placed in the ball mill with a ball ratio of 20 parts with a particle size of 0.6-1.0 mm, 120 parts with a particle size of 1.0-1.7 mm, and 160 parts with a particle size of 1.7-2.5 mm. Grinding for 50 minutes, the obtained slurry mineral admixture has a median particle size of 7 μm, which is obtained by stirring with 800 parts of 425 ordinary Portland cement, 780 parts of sand, 1080 parts of crushed stone, 3 parts of melamine water reducer and 250 parts of water. Concrete materials are cured by steam curing at 40°C for 8 hours, and after demoulding, standard curing (20°C, humidity 95%), and its performance indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com