Drilling rig derrick state online detection system and method

A detection system and derrick technology, which is applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve problems such as the inability to feedback the status of the derrick in real time, and the inability to monitor the status of the derrick.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below in conjunction with the examples and specific implementation methods, but this should not be interpreted as the scope of the above-mentioned subject of the present invention being limited to the following examples, and all technologies realized based on the content of the present invention belong to the present invention scope.

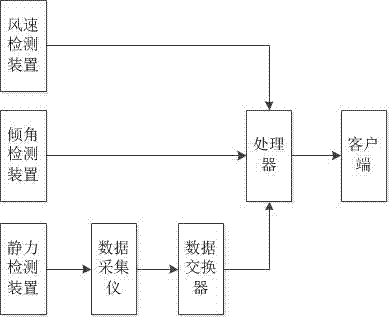

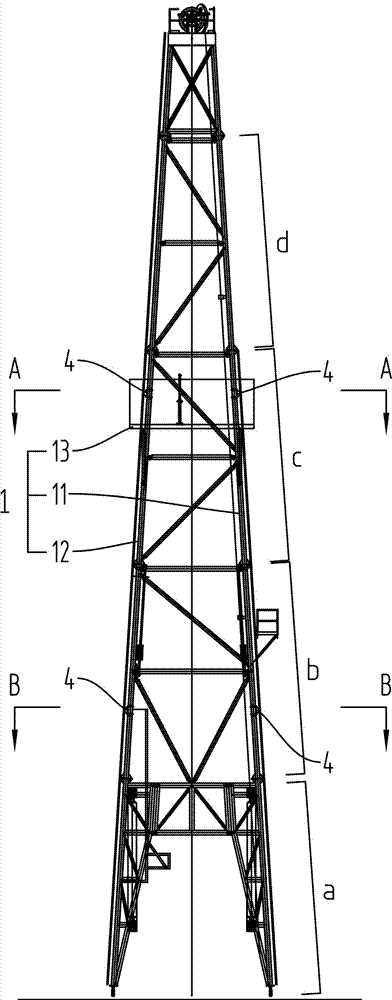

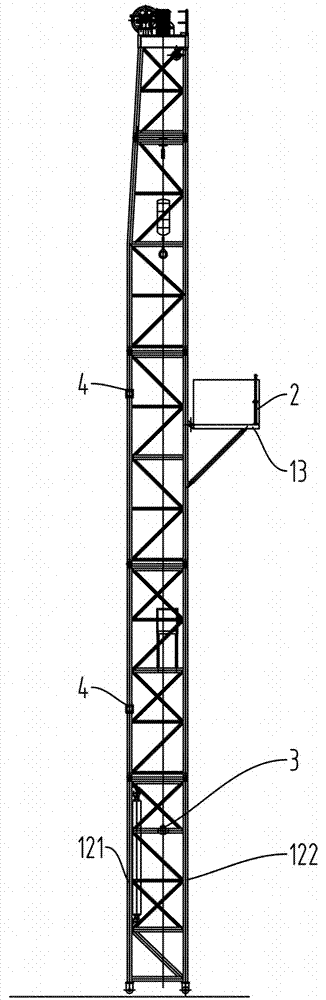

[0058] Such as figure 1 , figure 2 with image 3 As shown, an online detection system for the state of a drilling rig derrick includes a wind speed and direction detection device 2, an inclination detection device 3, a static force detection device 4, a data switch, a processor and a client, a wind speed and wind direction detection device 2, and an inclination detection device 3 1. The static detection device 4 is fixedly connected with the derrick 1 respectively, and the static detection device 4 is wired or wirelessly connected with the data switch, and the data switch collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com