Partial solid prestressed pile produced through centrifuge method, and production process

A technology of prestressed piles and production technology, which is applied in the direction of sheet pile walls, manufacturing tools, and foundation structure engineering, etc., which can solve the problems of troublesome production of solid prestressed piles, low safety in use, and short service life, and achieve quick demoulding , long service life and increased compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of part solid prestressed pile and production technology of centrifugation production, comprise the steps:

[0038] a: Material selection: cement, sand, stones, water reducing agent, rust inhibitor, third-grade threaded steel bar, and release agent, of which: cement 28%, sand 25%, stone 45%, water reducing agent 3%, rust inhibitor 3%;

[0039] b: Make concrete: Put the cement, sand and stones in step a into a concrete mixer for 20-35 minutes, and add water reducing agent and rust inhibitor during mixing to obtain the concrete used;

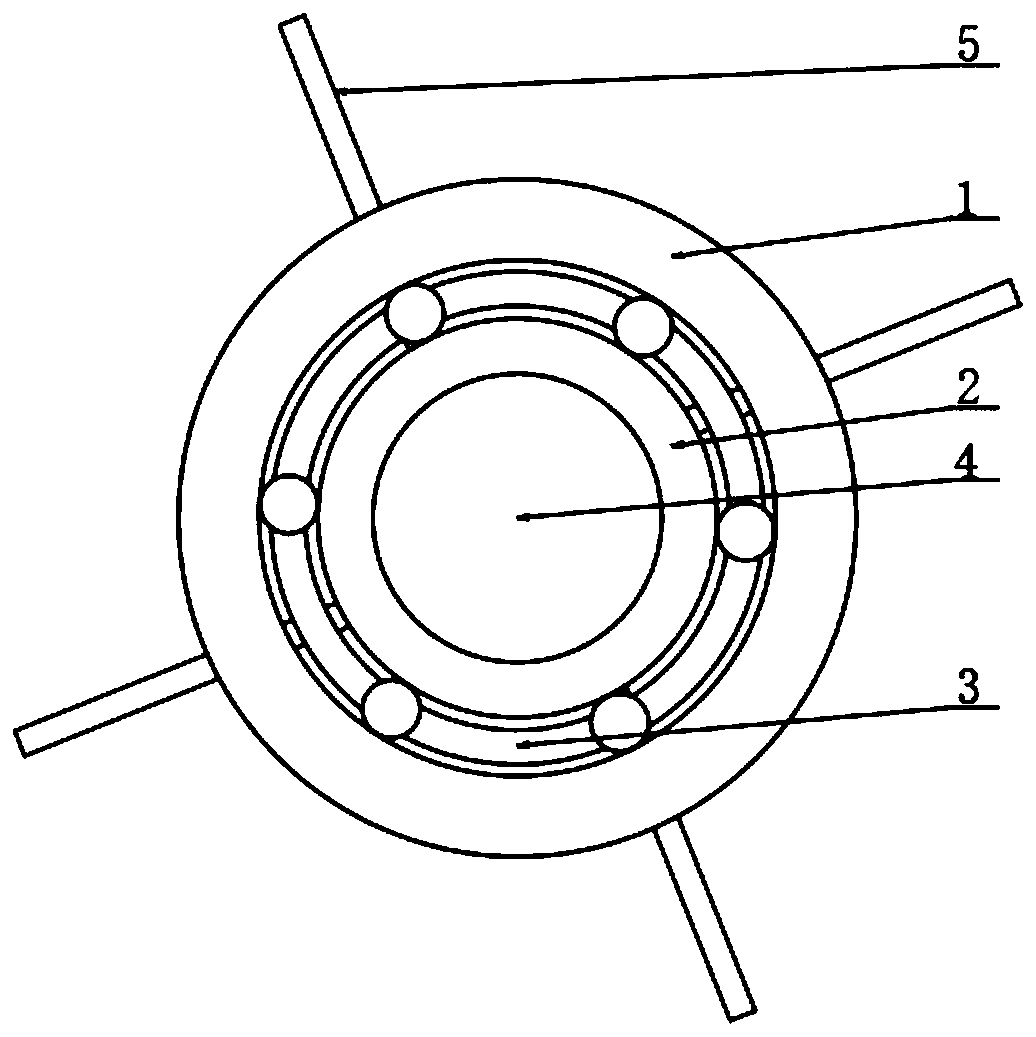

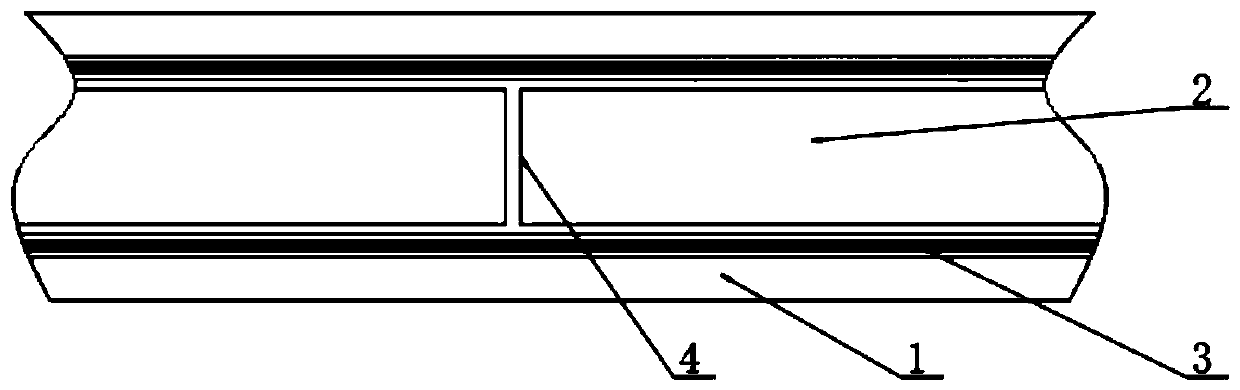

[0040] c: Make the cage frame: first stretch the third-grade threaded steel bars, and then weld or bundle them to make the inner steel bar cage and the outer bar bar cage, so that the inner bar bar cage is placed in the outer bar bar cage and the inner bar bar Relatively fixed, the threaded steel bars of the inner reinforcement cage and the outer reinforcement cage are parallel to form a reinforcement cage frame 3;

...

Embodiment 2

[0051] Embodiment 2: a kind of part solid prestressed pile and production technology that centrifugal method produces, comprise the steps:

[0052] a: Material selection: cement, sand, stones, water reducing agent, rust inhibitor, third-grade threaded steel bar, and release agent, of which: cement 32%, sand 35%, stone 55%, water reducing agent 7%, rust inhibitor 5%;

[0053] b: Make concrete: put the cement, sand and stones in step a into a concrete mixer for 35 minutes, and add water reducing agent and rust inhibitor during mixing to obtain the concrete used;

[0054] c: Make the cage frame: first stretch the third-grade threaded steel bars, and then weld or bundle them to make the inner steel bar cage and the outer bar bar cage, so that the inner bar bar cage is placed in the outer bar bar cage and the inner bar bar Relatively fixed, the threaded steel bars of the inner reinforcement cage and the outer reinforcement cage are parallel to form a reinforcement cage frame 3;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com