Frame-core tube structure with flexible inhaul cable

A flexible cable and core tube technology, applied in special structures, building components, etc., can solve problems such as instability, increase in the size of long inclined rods, failure to meet structural design reliability requirements, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

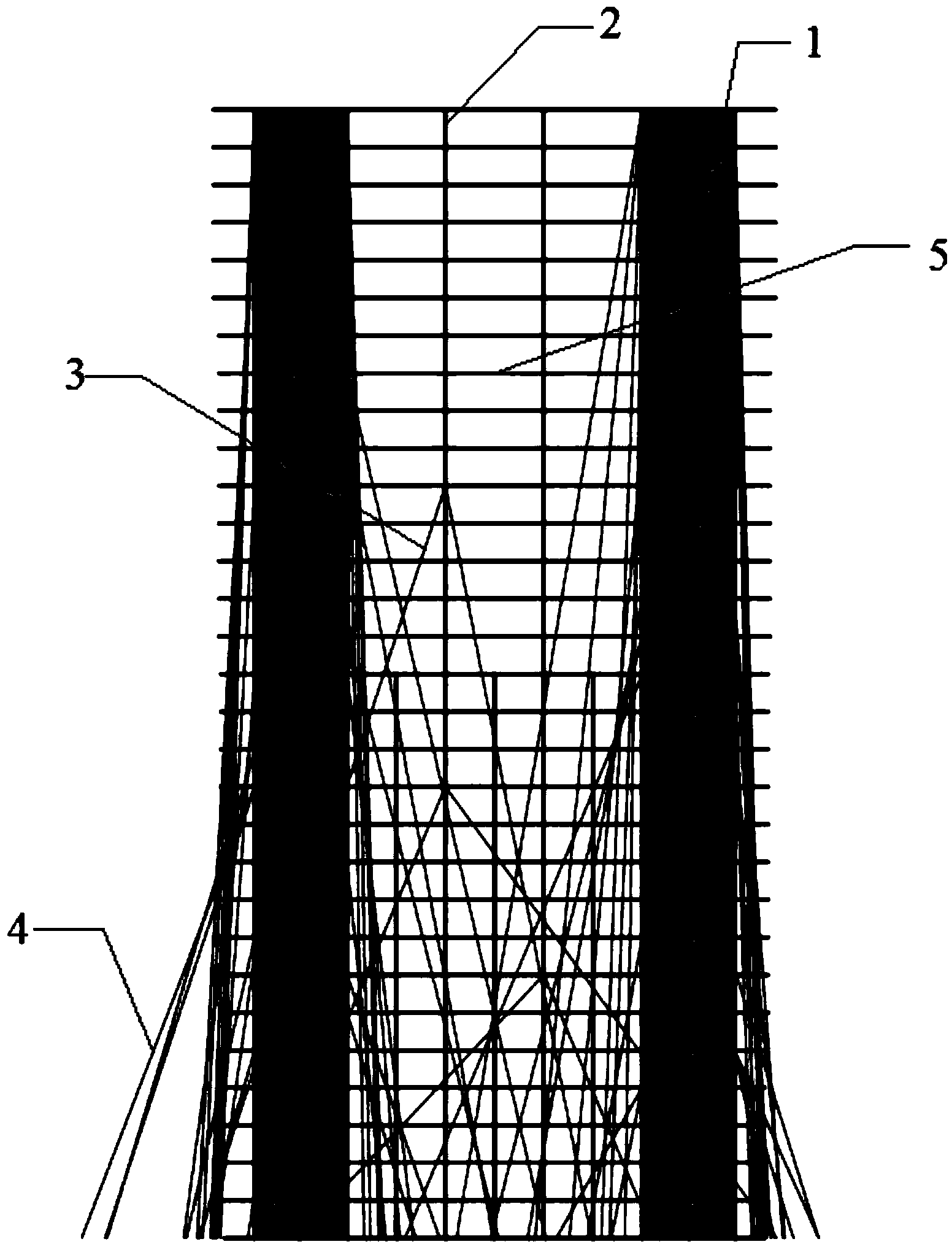

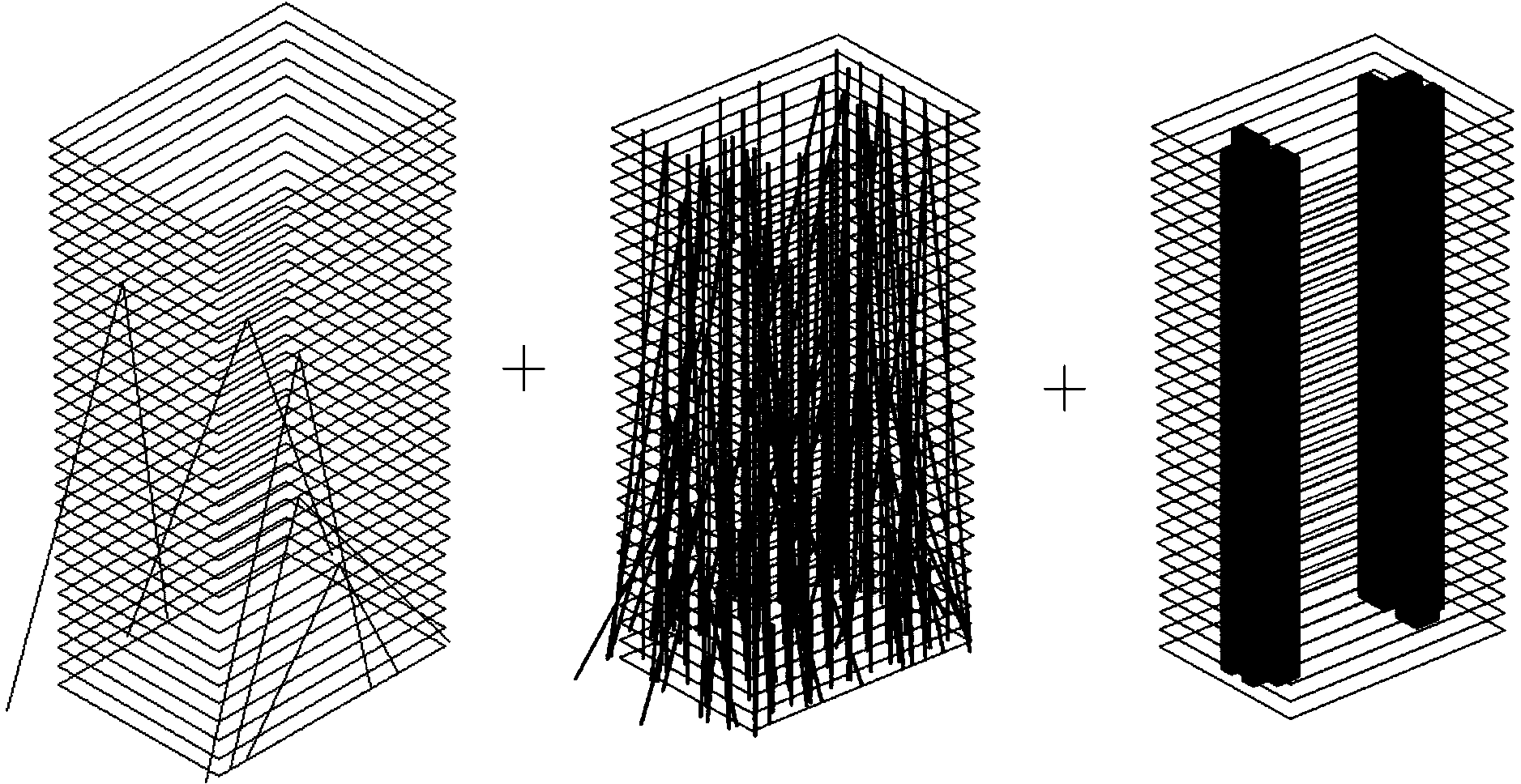

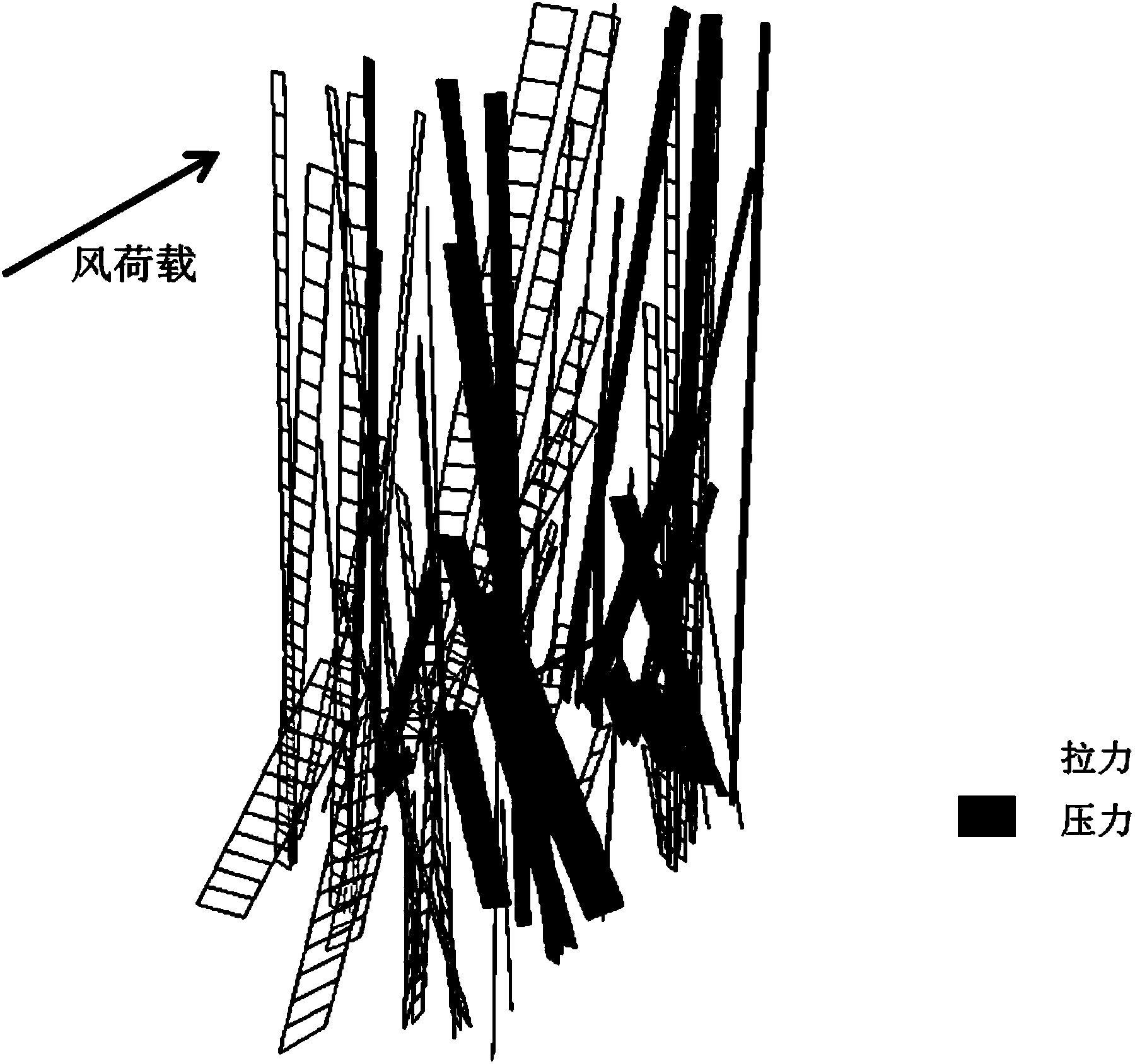

[0022] like Figure 1-Figure 2 As shown, a frame-core tube structure with flexible cables adds slanted columns to the traditional frame-core tube system. At the same time, the long slanted rods of the jump are made of flexible cables and prestressed to ensure that they are Building form under extreme loads and resisting lateral extreme loads by providing tension where necessary. The frame-core tube structure includes a core tube 1, frame columns 2, inclined columns 3, flexible stay cables 4, horizontal steel beams and composite floors 5, the frame columns 2 are evenly arranged outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com